Carbon cloth supported nickel sulfide-molybdenum sulfide heterogeneous nano-sheet array structure and preparation method thereof

A nanosheet array and nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as unfavorable production applications and cumbersome experimental steps, and achieve low cost, high-quality equipment and processes Simple, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

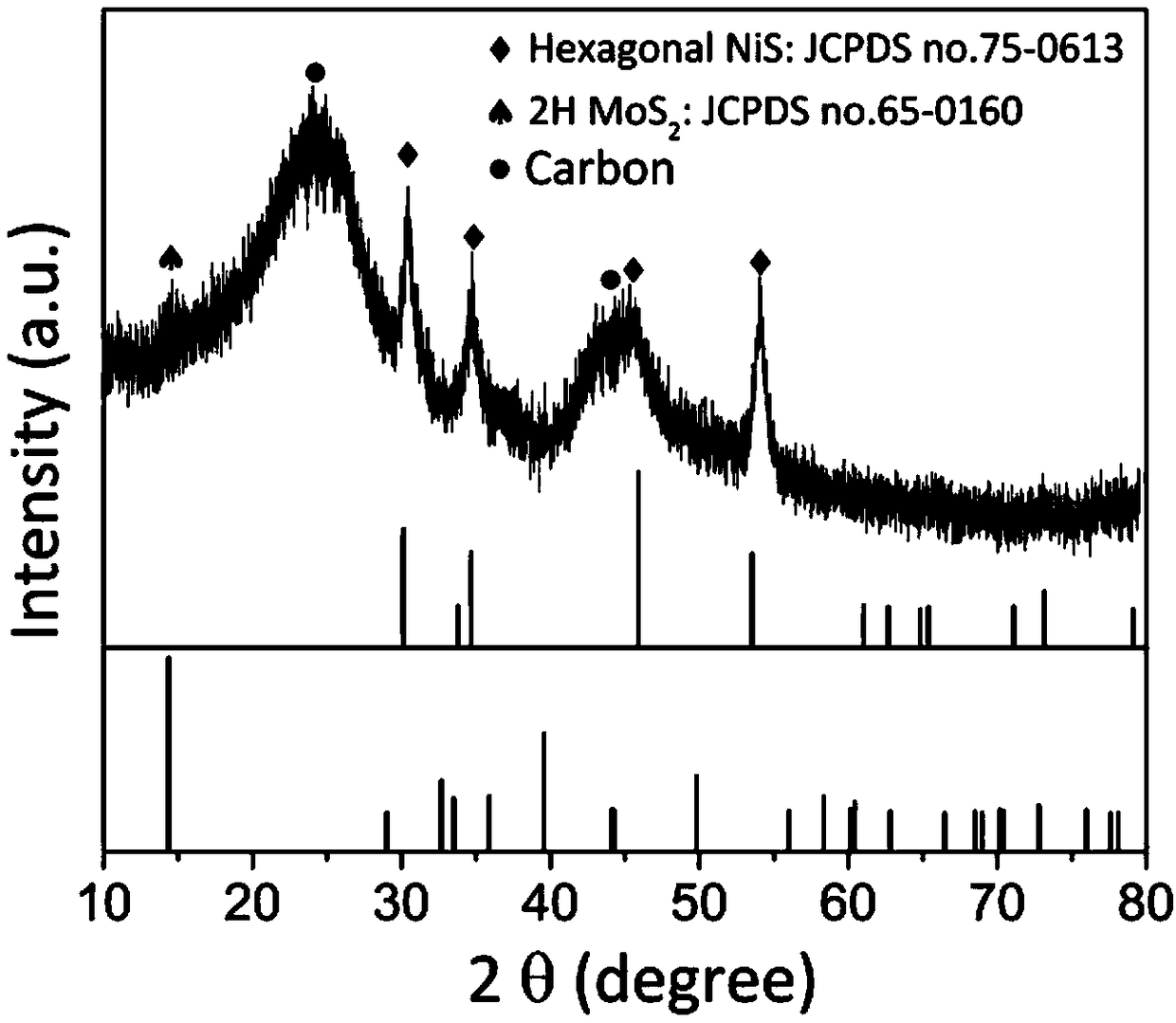

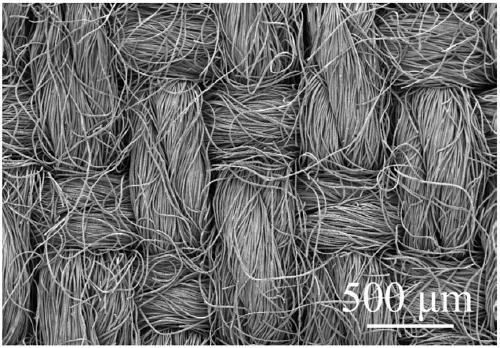

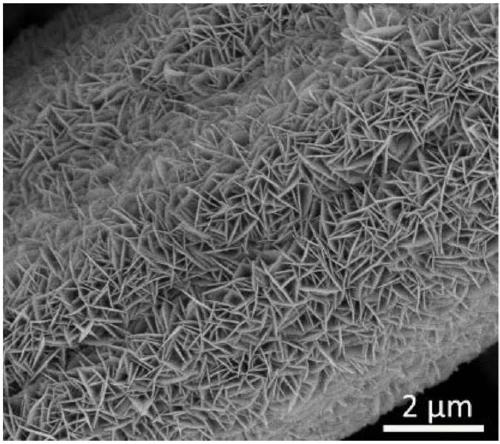

[0039] NiS-MoS supported by carbon cloth proposed by the present invention 2 The preparation method of the heterogeneous nanosheet array structure includes the following steps and contents in sequence:

[0040] (1) The carbon cloth is ultrasonically cleaned with acetone, 1-2 mol / L hydrochloric acid aqueous solution and deionized water for 0.5-1 hour in advance, and dried at 60°C, and stored for later use.

[0041] (2) Put commercially available analytically pure nickel acetate, ammonium molybdate, thiourea and sodium lauryl sulfate powder into a beaker, then add deionized water and stir to make it evenly mixed, and control the concentration of nickel acetate in the reactant mixed solution The concentration of ammonium molybdate is 0.001-0.005mol / L, the concentration of thiourea is 0.05-0.08mol / L, and the concentration of sodium lauryl sulfate is 0.15-0.25mol / L. Then use 0.5-1.0 mol / L sodium hydroxide aqueous solution to adjust the pH value of the reactant mixed solution to 5....

Embodiment 1

[0048] Example 1: A piece of carbon cloth with a size of 2.5×4cm was ultrasonically cleaned with acetone, 1mol / L hydrochloric acid aqueous solution and deionized water for 0.5 hours in advance, and dried at 60°C, and stored for later use.

[0049] In a 100mL beaker, add 0.224g nickel acetate, 0.074g ammonium molybdate, 0.137g thiourea and 1.73g sodium lauryl sulfate, then add 30mL deionized water and stir until the solution is clear; slowly drop 0.5mol / L sodium hydroxide aqueous solution adjusts the pH value of reactant mixed solution to 6.5; Then the reaction mixed solution is all transferred in the 40mL high-pressure hydrothermal reaction kettle, after the carbon cloth that cleans is vertically immersed in the solution, seal the reaction kettle; Then The reactor was moved to an electric furnace, heated to 180°C at a rate of 5°C / min and reacted for 9 hours.

[0050] After naturally cooling to room temperature, open the reactor, take out the carbon cloth and rinse it with dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com