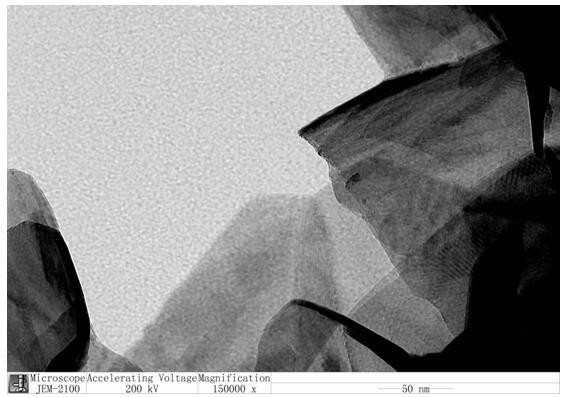

Preparation method of composite positive electrode material for lithium-sulfur battery with nanosheet layered structure

A composite positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of difficult commercial production of lithium-sulfur batteries, low conductivity of sulfur positive electrodes, fast capacity decay, etc., to achieve excellent cycle Excellent performance, good cycle stability, and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

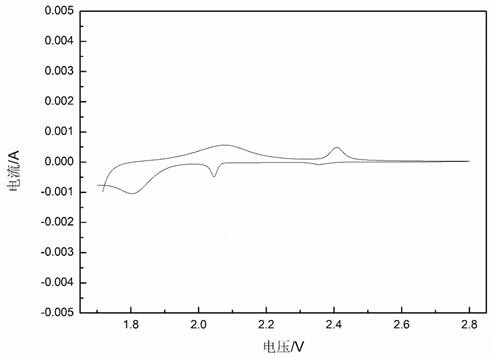

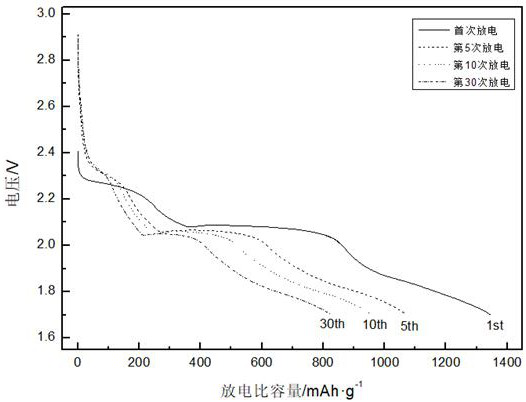

Image

Examples

Embodiment 1

[0029] A method for preparing a composite cathode material for a lithium-sulfur battery with a nanosheet layered structure, specifically comprising the following steps:

[0030] (1) Add nickel chloride into N,N-dimethylformamide according to the mass volume ratio g:mL of 1:150, stir with a magnetic stirrer combined with ultrasonic dispersion for 30 minutes to obtain a mixed solution A; Diformic acid is added to the mixed solvent according to the ratio of mass volume ratio g:mL of 1:100, and the magnetic stirrer is combined with ultrasonic dispersion for 30 minutes to mix to obtain the mixed solution B. The mixed solvent is N,N-dimethylformamide, ethanol and The water is mixed according to the volume ratio of 5:1:1, the magnetic stirring speed of the magnetic stirrer combined with the ultrasonic treatment is 500 rpm, and the ultrasonic power is 100W;

[0031] (2) Mix the mixed solution A and the mixed solution B in step (1) according to the molar ratio of nickel chloride and te...

Embodiment 2

[0040] A method for preparing a composite cathode material for a lithium-sulfur battery with a nanosheet layered structure, specifically comprising the following steps:

[0041](1) Add nickel chloride into N,N-dimethylformamide according to the mass volume ratio g:mL of 1:180, stir with a magnetic stirrer combined with ultrasonic dispersion for 30 minutes to obtain a mixed solution A; Diformic acid is added into the mixed solvent according to the ratio of mass volume ratio g:mL of 1:120, and the magnetic stirrer is combined with ultrasonic dispersion for 30 minutes to mix to obtain the mixed solution B. The mixed solvent is N,N-dimethylformamide, ethanol and The water is mixed according to the volume ratio of 4:1:1, the magnetic stirring speed of the magnetic stirrer combined with the ultrasonic treatment is 1000 rpm, and the ultrasonic power is 200W;

[0042] (2) Mix the mixed solution A and the mixed solution B in step (1) according to the molar ratio of nickel chloride and ...

Embodiment 3

[0047] A method for preparing a composite cathode material for a lithium-sulfur battery with a nanosheet layered structure, specifically comprising the following steps:

[0048] (1) Add nickel chloride into N,N-dimethylformamide according to the mass volume ratio g:mL of 1:200, stir with a magnetic stirrer combined with ultrasonic dispersion for 30 minutes to obtain a mixed solution A; Diformic acid is added into the mixed solvent according to the ratio of mass volume ratio g:mL of 1:150, and the magnetic stirrer is combined with ultrasonic dispersion for 30 minutes to mix to obtain the mixed solution B. The mixed solvent is N,N-dimethylformamide, ethanol and The water is mixed according to the volume ratio of 3:1:1, the magnetic stirring speed of the magnetic stirrer combined with the ultrasonic treatment is 800 rpm, and the ultrasonic power is 300W;

[0049] (2) Mix the mixed solution A and the mixed solution B in step (1) according to the molar ratio of nickel chloride and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com