Tungsten/PEEK radiation protection composite wire for 3D printing and preparation method thereof

A composite wire and radiation protection technology, applied in the field of tungsten/PEEK radiation protection composite wire and its preparation, can solve the problems of shortening the shutdown time of nuclear power equipment, poor structural performance of shielding components, and low mechanical strength, so as to shorten equipment shutdown Effect of time, super mechanical properties, excellent radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments.

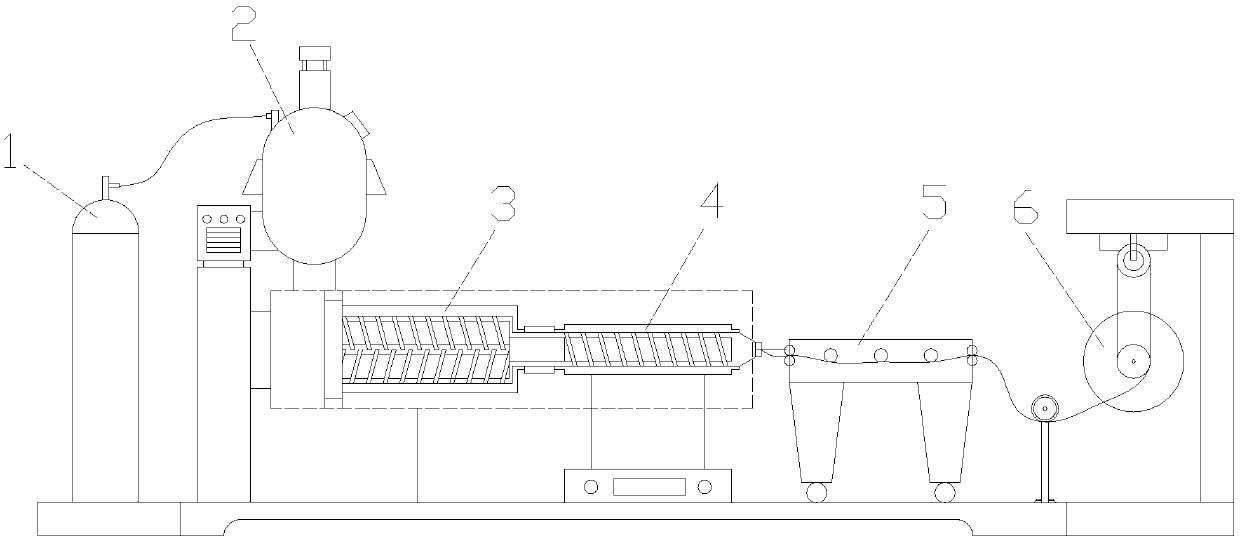

[0020] like figure 1 shown. The equipment used in the preparation process of the present invention is existing equipment; Among the figure: argon cylinder 1, reactor 2, twin-screw extruder 3, single-screw extruder 4, wire rod leveler 5, coiler 6 ;

[0021] Reactor 2 has a built-in stirring device, which is externally connected to argon cylinder 1; reactor 2 is connected to the feed port of twin-screw extruder 3, and argon cylinder 1 provides inert gas protection for reactor 2;

[0022] The outlet of the twin-screw extruder 3 is connected to the feed inlet of the single-screw extruder 4, and the outlet of the single-screw extruder 4 is connected to the wire leveler 5;

[0023] The wire leveling machine 5 leveles the wire through rollers, and has a built-in temperature sensor and a cooler; the temperature sensor detects the temperature of the wire, and the cooler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com