Sunlight self-repairing transparent flexible strain sensing composite material, preparation method and applications thereof

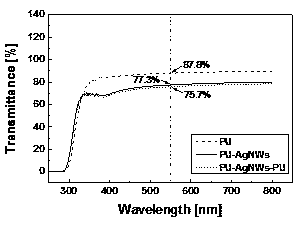

A composite material and strain sensing technology, which is applied in the field of solar self-repairing transparent flexible strain sensing composite materials and its preparation, can solve the problem of being easily affected by various environmental factors, or subjected to repeated bending, extrusion or Stretch and flexible strain sensors have high cost and reduced electrical conductivity, etc., to achieve excellent light transmittance, sensitive response to tensile strain, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Preparation of polyurethane solution

[0070] Polyurethane is prepared by reacting 15-28 parts of diisocyanate monomer, 10-50 parts of polyethylene glycol monomer, 5-15 parts of disulfide bond-containing monomer, and 0.5-2.5 parts of cross-linking agent. The specific preparation process is as follows: Disulfide bond-containing monomers, polyethylene glycol monomers and diisocyanate monomers undergo polymerization reactions to generate disulfide bond-containing polyurethane linear prepolymers; the disulfide bond-containing polyurethane linear prepolymers are combined with crosslinked Reaction of reagents to obtain the polyurethane. For the preparation of polyurethane, reference may be made to the examples in the patent CN105669932A.

[0071] In this example, 9.96g of isophorone diisocyanate, 3.20g of bis(2-hydroxyethyl) disulfide and 8.00g of polyethylene glycol 400 (PEG400, with a molecular weight of 400) were weighed and dissolved in 150mL of anhydrous In dichlor...

Embodiment 2

[0079] (1) Preparation of polyurethane solution

[0080] Weigh 9.96g isophorone diisocyanate, 3.20g bis(2-hydroxyethyl) disulfide and 8.00g polyethylene glycol 400 (PEG400, molecular weight is 400) and dissolve in 150mL anhydrous dichloromethane, in Under the protection of argon, react at 60° C. for 10 h, add 0.2 g of triethanolamine, and continue to react for 3 h to obtain a polyurethane solution.

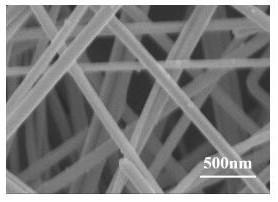

[0081] (2) Preparation of silver nanowires

[0082] Weigh 1.0g of silver nitrate and 1.0g of polyvinylpyrrolidone (K-90), add them into 100mL of ethylene glycol, stir well to dissolve. Then pour it into a 250mL hydrothermal reaction kettle, add 0.005g concentrated hydrochloric acid, mix well, heat to 140°C, and react for 16h. Cool to room temperature after the reaction, separate with a 200-1000-mesh standard sieve, wash with industrial alcohol, and finally disperse in dichloromethane to obtain a dichloromethane dispersion of silver nanowires.

[0083] This embodiment provides a...

Embodiment 3

[0086] (1) Preparation of polyurethane solution

[0087] Weigh 9.96g isophorone diisocyanate, 3.20g bis(2-hydroxyethyl) disulfide and 8.00g polyethylene glycol 400 (PEG400, molecular weight is 400) and dissolve in 150mL anhydrous dichloromethane, in Under the protection of argon, react at 60° C. for 10 h, add 0.2 g of triethanolamine, and continue to react for 3 h to obtain a polyurethane solution.

[0088] (2) Preparation of silver nanowires

[0089] Weigh 1.0g of silver nitrate and 1.5g of polyvinylpyrrolidone (K-60), add them into 100mL of ethylene glycol, stir well to dissolve. Then pour it into a 250mL hydrothermal reaction kettle, add 0.002g of concentrated hydrochloric acid, mix well, heat to 140°C, and react for 15h. Cool to room temperature after the reaction, separate with a 200-1000-mesh standard sieve, wash with industrial alcohol, and finally disperse in ethanol to obtain an ethanol dispersion of silver nanowires.

[0090] This embodiment provides a non-sandwic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com