Glass fibre reinforced plastic septic-tank glue and preparation method thereof

A glass tempering and septic tank technology, applied in the field of glass fiber reinforced plastics, can solve problems such as poor temperature resistance, odor generation, human health hazards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

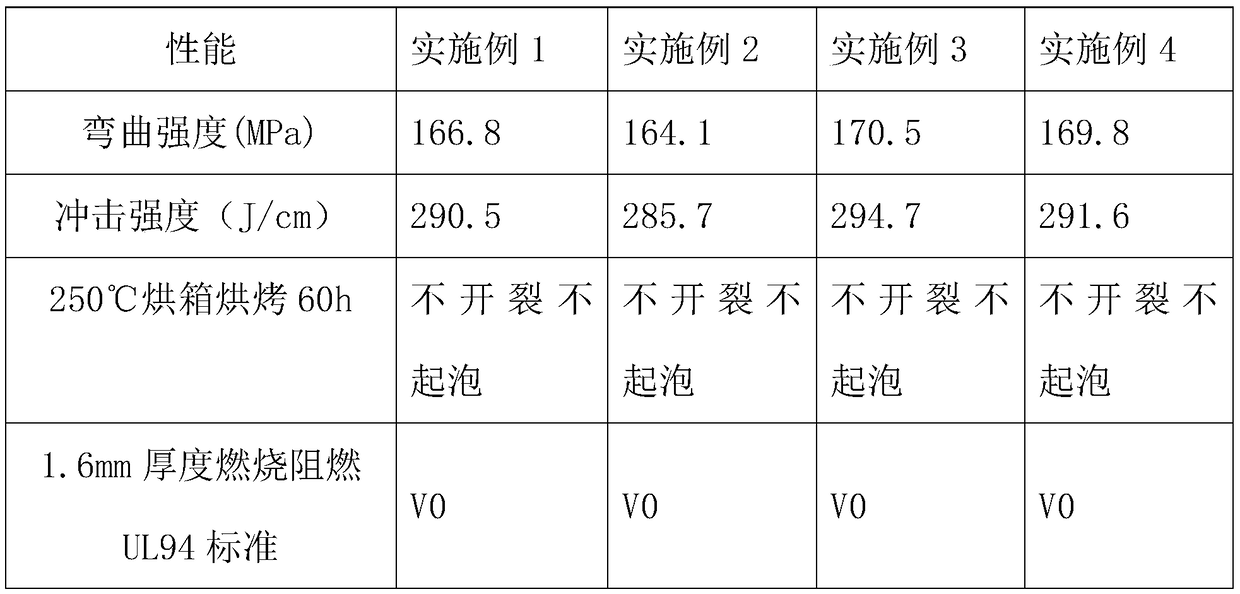

Examples

Embodiment 1

[0021] A kind of fiberglass septic tank compound, its raw material comprises by weight: 20 parts of unsaturated polyester resin, 20 parts of epoxy-modified phenolic resin, 8 parts of glass fiber, 15 parts of flame retardant, 6 parts of silicon carbide micropowder, 10 parts of quartz powder, 1 part of calcium stearate, 10 parts of titanate coupling agent, 0.1 part of antioxidant, 0.3 part of lubricant;

[0022] Wherein, the unsaturated polyester resin is prepared by the following process: 17 parts by weight of maleic anhydride, 28 parts of tetrahydrophthalic anhydride, 4 parts of adipic acid, 38 parts of propylene glycol, 4 parts of diethylene glycol After mixing the parts, raise the temperature to 160°C and stir the reaction for 0.5h, continue to raise the temperature to 220°C, stir the reaction until the acid value is lower than 15mgKOH / g, cool down to 90°C, pass nitrogen, and then add N-(polydimethylsilane Mix 12 parts of oxane)maleimide and 0.1 part of dibenzoyl peroxide, h...

Embodiment 2

[0026] A kind of fiberglass septic tank compound, its raw material comprises by weight: 40 parts of unsaturated polyester resin, 10 parts of epoxy modified phenolic resin, 15 parts of glass fiber, 5 parts of flame retardant, 18 parts of silicon carbide micropowder, 4 parts of quartz powder, 5 parts of calcium stearate, 3 parts of titanate coupling agent, 0.5 part of antioxidant, 0.1 part of lubricant;

[0027]Wherein, the unsaturated polyester resin is prepared by the following process: 28 parts by weight of maleic anhydride, 12 parts of tetrahydrophthalic anhydride, 12 parts of adipic acid, 23 parts of propylene glycol, 8 parts of diethylene glycol After mixing the parts, heat up to 140°C and stir for 1 hour, continue to heat up to 200°C, stir and react until the acid value is lower than 15mgKOH / g, cool down to 100°C, pass nitrogen, and then add N-(polydimethylsiloxane Mix 5 parts of alk)maleimide and 0.5 part of dibenzoyl peroxide, heat up to 120°C, stir and react for 1 h, a...

Embodiment 3

[0031] A kind of fiberglass septic tank compound, its raw material comprises by weight: 30 parts of unsaturated polyester resins, 15 parts of epoxy-modified phenolic resins, 12 parts of glass fibers, 10 parts of flame retardants, 12 parts of silicon carbide micropowders, 7 parts of quartz powder, 3 parts of calcium stearate, 6 parts of titanate coupling agent, 0.3 part of antioxidant, 0.2 part of lubricant;

[0032] Wherein, the unsaturated polyester resin is prepared by the following process: 23 parts by weight of maleic anhydride, 20 parts of tetrahydrophthalic anhydride, 8 parts of adipic acid, 30 parts of propylene glycol, 6 parts of diethylene glycol After mixing the parts, raise the temperature to 145°C, stir and react for 0.8h, continue to raise the temperature to 205°C, stir and react until the acid value is lower than 15mgKOH / g, cool down to 95°C, pass nitrogen, and then add N-(polydimethylsilane Mix 8 parts of oxane)maleimide and 0.3 parts of dibenzoyl peroxide, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com