Graphite phase carbon nitride foam composite cuprous oxide quantum dot photocatalytic material and preparation method thereof

A technology of graphite phase carbon nitride and photocatalytic materials, applied in the field of photocatalytic materials, can solve the problems of not effectively improving the adsorption capacity and reduction, and achieve the effect of reducing scale, reducing recombination probability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The g-C 3 N 4 The preparation method of foam is: the g-C of 5~14 mass parts 3 N 4 Added into 100 parts by mass of deionized water, mixed evenly to obtain a suspension; 1.7 to 2.0 parts by mass of sodium dodecylsulfonate, 1.7 to 2.0 parts by mass of dodecyl alcohol and 1.7 parts by mass were added to the suspension ~2.0 parts by mass of resin glue, stirred at 40~60°C and 100~200r / min for 10~20min to obtain a mixed solution; under the condition of a rotating speed of 1500~2000r / min, stirred the mixed solution for 15~20min , and then add 5 to 14 parts by mass of binder to the mixed solution under stirring, and continue to stir for 5 to 10 minutes to obtain g-C 3 N 4 foam slurry; then the g-C 3 N 4 The foam slurry is poured and molded, freeze-dried for 6-12 hours, and dried at 80-100°C for 18-24 hours to obtain g-C 3 N 4 Foam.

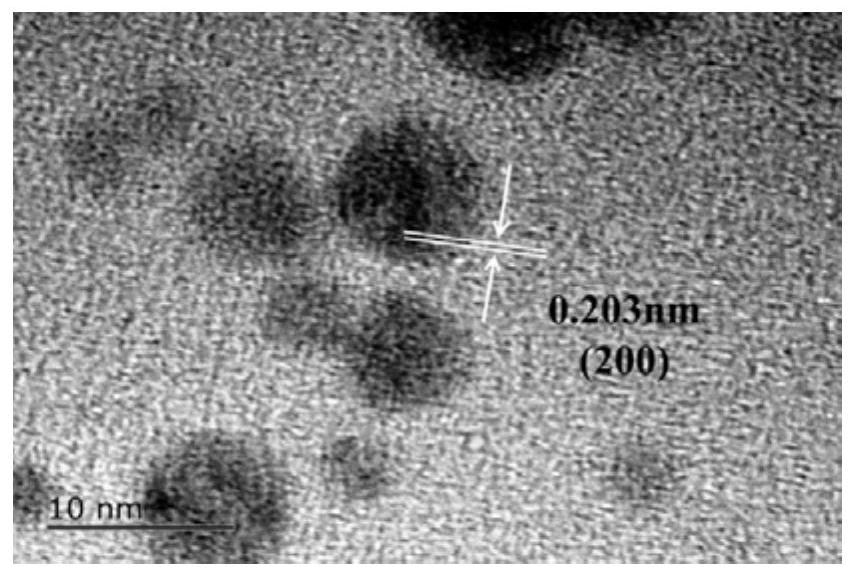

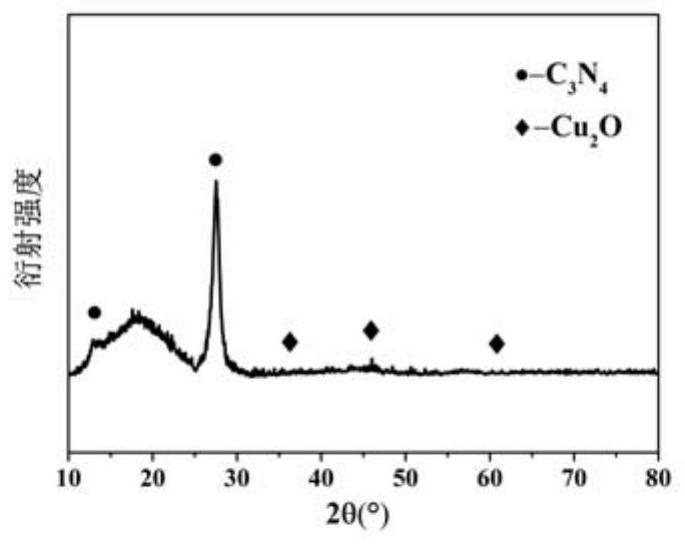

[0025] The g-C 3 N 4 The particle size is 1~20μm, g-C 3 N 4 The main chemical components are: C is 28-30wt%, N is 38-40wt%, and O is 2...

Embodiment 1

[0028] A graphite phase carbon nitride foam composite cuprous oxide quantum dot photocatalytic material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0029] Step 1, 10-12 mass parts of anhydrous methanol and 10-12 mass parts of hydrogen peroxide solution are dissolved in 100 mass parts of CuSO 4 solution, stir evenly to obtain the mixed solution I; then add 0.1 to 0.2 parts by mass of g-C to the mixed solution I 3 N 4 Bubbles, stirred for 10-14 minutes to obtain the mixed solution II.

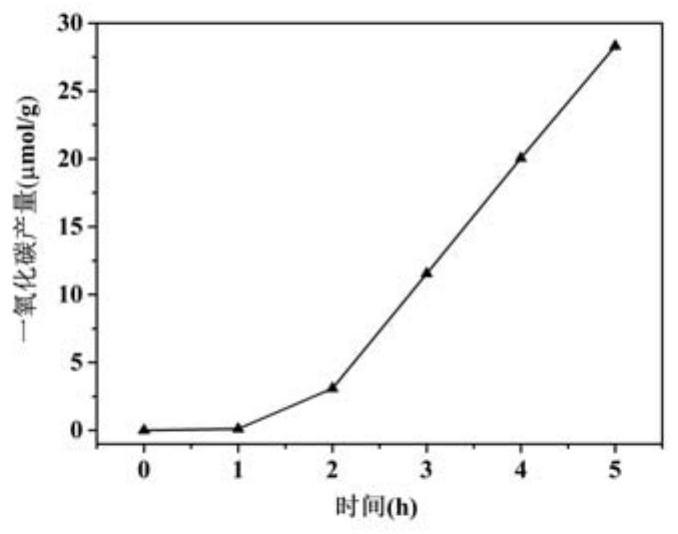

[0030] Step 2, reacting the mixed liquid II under the conditions of nitrogen atmosphere and 300W mercury lamp irradiation for 1-2 hours to obtain a reaction liquid.

[0031] Step 3: Filter the reaction solution, take the filter residue, wash and dry to prepare a graphite phase carbon nitride foam composite cuprous oxide quantum dot photocatalytic material.

[0032] CuSO described in this example 4 The concentration of the solution...

Embodiment 2

[0035] A graphite phase carbon nitride foam composite cuprous oxide quantum dot photocatalytic material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0036] Step 1. Dissolve 11-13 parts by mass of anhydrous methanol and 11-13 parts by mass of hydrogen peroxide solution in 100 parts by mass of CuSO 4 solution, stir evenly to obtain a mixed solution I; then add 0.2 to 0.3 parts by mass of g-C to the mixed solution I 3 N 4 Bubbles, stirred for 12 to 16 minutes to obtain the mixed solution II.

[0037] Step 2, reacting the mixed solution II for 2-3 hours under the conditions of nitrogen atmosphere and 300W mercury lamp irradiation, to obtain a reaction solution.

[0038] Step 3: Filter the reaction solution, take the filter residue, wash and dry to prepare a graphite phase carbon nitride foam composite cuprous oxide quantum dot photocatalytic material.

[0039] CuSO described in this example 4 The concentration of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com