Aquagel, preparation method therefor and application of aquagel

A hydrogel and reaction technology, used in medical science, bandages, etc., can solve the problems of insignificant bacteriostatic effect and drug resistance, and achieve the effects of no cytotoxicity, reduction of reaction steps, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

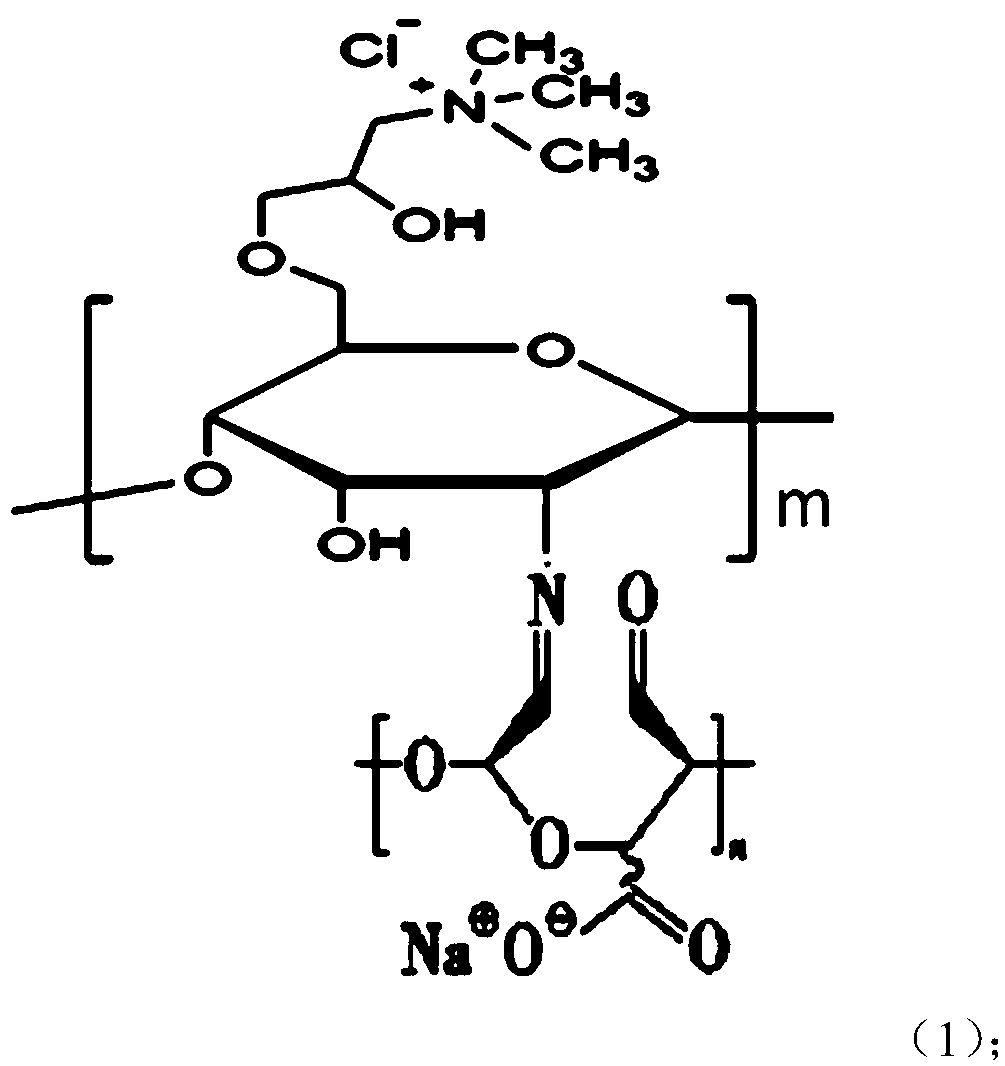

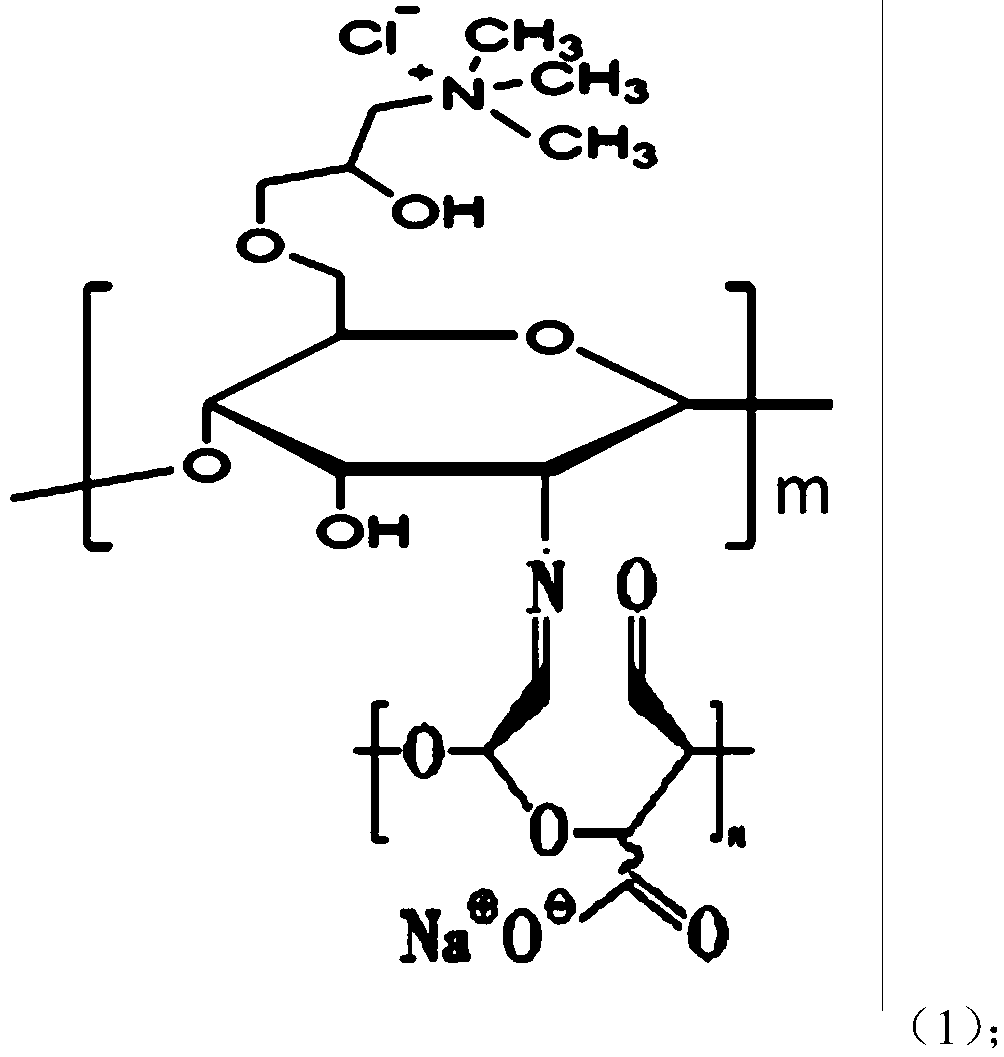

[0035] A preparation method of the hydrogel comprises mixing and reacting an O-quaternary ammonium salt chitosan solution and an aldehyde sodium alginate solution to obtain a product with a structure shown in formula (1).

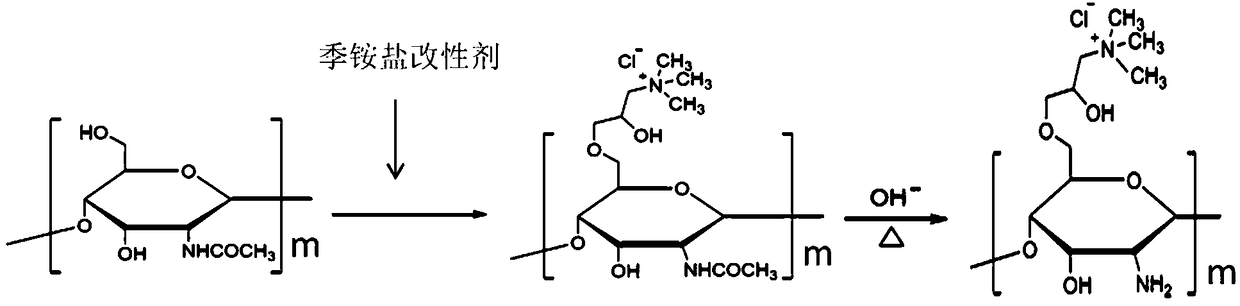

[0036] Further, in the preparation method, the O-quaternary ammonium salt chitosan is prepared by modifying chitin with a quaternary ammonium salt modifier.

[0037] What is explained here is that O-quaternary ammonium chitosan refers to the introduction of quaternary ammonium salt at the C-6 position in the molecular structure of chitosan to synthesize O-quaternary ammonium chitosan with a certain degree of substitution. The following quaternary ammonium chitosan refers to O-quaternary ammonium chitosan unless otherwise specified.

[0038] Further, in the preparation method, the aldehyde sodium alginate is prepared from sodium alginate through an oxidation reaction.

[0039] Further, the mixed reaction is a Schiff base reaction.

[0040] The preparation ...

Embodiment 1

[0079] The hydrogel preparation method of embodiment 1 is as follows:

[0080] Weigh 1g of chitin, dissolve it in 30mL of isopropanol, stir at room temperature for 2 hours, add 7g of (3-chloro-2-hydroxypropyl)trimethylammonium chloride reagent, stir for 2 hours, and then add to the reaction solution 40wt% NaOH solution was added to the reaction solution at 50°C for 8 hours. After the reaction is completed, filter, remove the supernatant, wash repeatedly with ethanol, and then dry at 40° C. to remove the ethanol to obtain a crude quaternized chitosan product. The crude product was dissolved in 10 ml of distilled water, fully stirred and filtered, the filtrate was washed with 30 ml of acetone, the precipitate was precipitated and filtered, and the step of washing with acetone was repeated 3 times. Dissolve the precipitate obtained by filtration with 20 mL of distilled water, dialyze the solution for 2 days with a dialysis bag to remove small molecular substances; filter with su...

Embodiment 2

[0085] The hydrogel preparation method of embodiment 2 is as follows:

[0086] Weigh 1g of chitin, dissolve it in 30mL of isopropanol, stir at room temperature for 2 hours, add 3.7g of 2,3-epoxypropyltrimethylammonium chloride reagent, stir for 2 hours, and then add 50wt% NaOH solution was reacted at 70°C for 8 hours. After the reaction is completed, filter, remove the supernatant, wash repeatedly with ethanol, and then dry at 40° C. to remove the ethanol to obtain a crude quaternized chitosan product. The crude product was dissolved in 10 ml of distilled water, fully stirred and filtered, the filtrate was washed with 30 ml of acetone, the precipitate was precipitated and filtered, and the step of washing with acetone was repeated 3 times. Dissolve the precipitate obtained by filtration with 20 mL of distilled water, dialyze the solution for 2 days with a dialysis bag to remove small molecular substances; filter with suction and dry in vacuum to obtain purified quaternary amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com