3D porous current collector and preparation method and application thereof

A porous current collector, 3D technology, applied in the field of energy storage, can solve the problems of high reactivity, active material consumption, aggravation, etc., to achieve the effect of increasing the specific surface area and reducing the local current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A 3D porous current collector, the preparation method of which comprises the following steps: commercial copper foil is punched into a disc with a diameter of 14 mm, and then washed with acetone, ethanol, hydrochloric acid and deionized water to remove surface impurities and oxides, and the cleaned The final copper foil disc was soaked in the mixed solution of ammonium persulfate and sodium hydroxide (ammonium persulfate and sodium hydroxide were configured according to the ratio of the amount of substance to 1:20) for 15 minutes, taken out and washed with deionized water, After washing with ethanol, dry it in air for 12 hours, then put it into a tube furnace and heat it from room temperature to 180 °C at a heating rate of 2 °C / min and keep it warm for 4 hours, then air-cool to room temperature to obtain a 3D porous current collector.

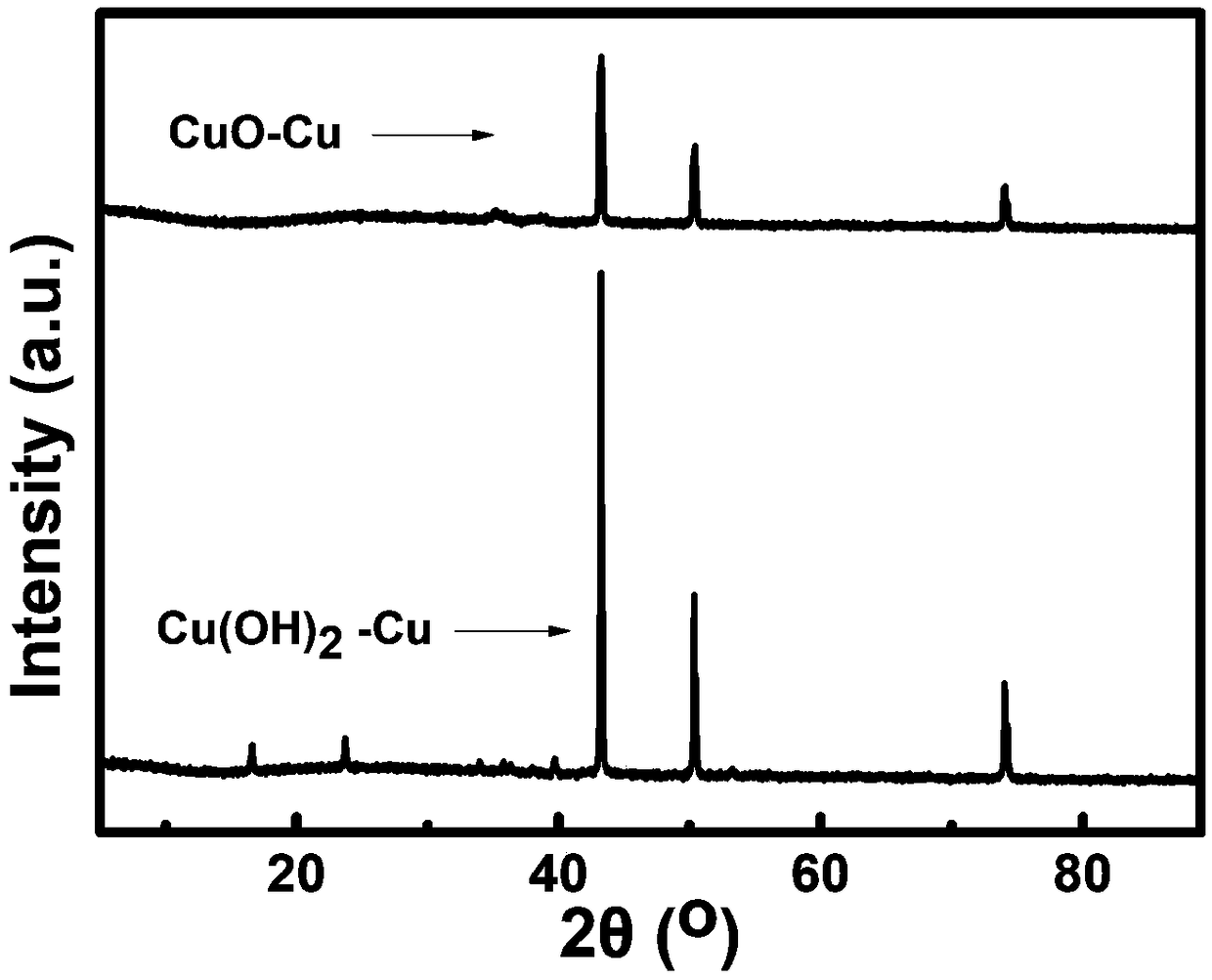

[0021] Such as figure 1 As shown, five peaks at 35.5°, 38.8°, 43.3°, 50.4°, and 74.3° in the figure correspond to the XRD standard peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com