Preparation method of amorphous mono-crystalline precursor oxide

A precursor and amorphous technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems affecting battery cycle performance and charge-discharge stability, high-temperature cycle performance and rate performance, single crystal structure and crystallinity To achieve the effect of improving high-temperature cycle performance and high-temperature rate performance, good high-temperature safety performance and high-temperature rate performance, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

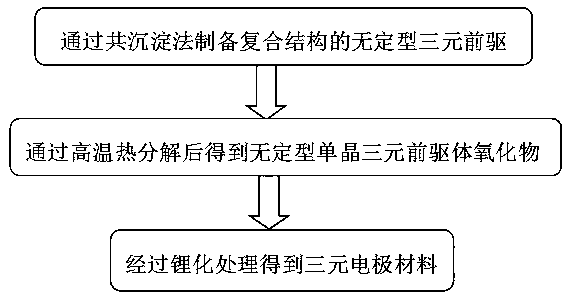

[0032] as attached figure 1 Shown, a kind of preparation method of amorphous single crystal precursor oxide comprises the following steps:

[0033] S1, Amorphous ternary precursor with composite structure prepared by co-precipitation method;

[0034] S101, preparing a metal salt solution and a liquid caustic solution as a raw and auxiliary material solution for coprecipitation reaction, adding pure water to the effective volume position of the reaction kettle, heating the pure water in the reaction kettle, and then adding the prepared liquid caustic solution to adjust the pH range to obtain a co-precipitation reaction. The bottom solution of the precipitation reaction;

[0035] In S101, the metal salt solution is prepared by mixing nickel salt, cobalt salt, and manganese salt according to the traditional process. The total metal ion solubility of the prepared liquid alkali solution is 0.5-2mol / L. Concentration of 3-12mol / L, nickel salt, cobalt salt, manganese salt is at leas...

Embodiment 1

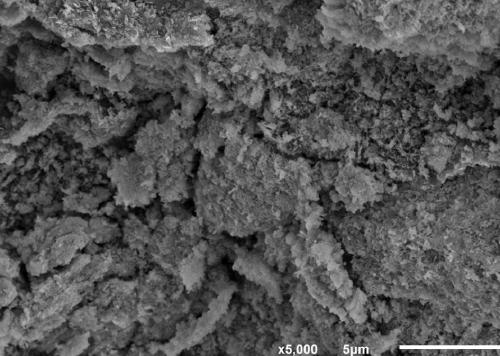

[0047] First, add pure water to the reactor and heat it to 40°C, then add the prepared liquid caustic soda solution to adjust the pH to 11.0, and mix the stirring blades inside the reactor at a speed of 300r / min to prepare the bottom liquid of the co-precipitation reaction , then add the metal salt solution of 0.5mol / L and the liquid caustic soda solution of 3mol / L with the flow rate of 15L / h, after the co-precipitation reaction of 2 hours takes place in the reactor, flow out from the discharge port of the reactor, obtain The solid-liquid mixed amorphous ternary precursor slurry is washed with impurities, filtered, dehydrated, and dried to obtain an amorphous ternary precursor with a composite structure. The amorphous ternary precursor is subjected to high-temperature thermal decomposition treatment at a temperature of 500°C , the high-temperature thermal decomposition treatment time is 8 hours, after the powder material after high-temperature heat treatment is collected, crush...

Embodiment 2

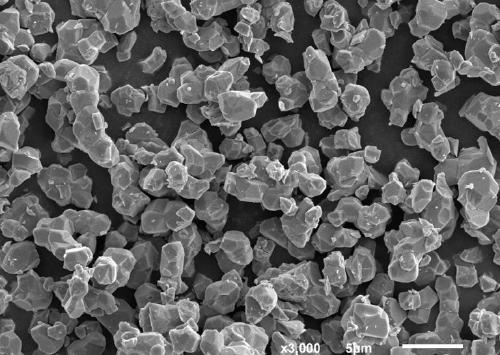

[0049] First, add pure water to the reactor and heat it to 55°C, then add the prepared liquid caustic soda solution to adjust the pH to 12.0, and mix the stirring blades inside the reactor at a speed of 450r / min to prepare the bottom liquid for coprecipitation reaction , then add the metal salt solution of 1.25mol / L and the liquid caustic soda solution of 9mol / L with the flow rate of 60L / h, after coprecipitation reaction takes place in reactor for 11 hours, flow out from the outlet of reactor, obtain The solid-liquid mixed amorphous ternary precursor slurry is washed with impurities, filtered, dehydrated, and dried to obtain an amorphous ternary precursor with a composite structure. The amorphous ternary precursor is subjected to high-temperature thermal decomposition treatment at a temperature of 750°C , the high-temperature thermal decomposition treatment time is 22 hours. After the powder material after high-temperature heat treatment is collected, crushed, classified, sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com