A lithium-replenishing porous silicon monoxide negative electrode material used in a lithium ion battery and a preparation method thereof

A lithium-ion battery, silicon monoxide technology, applied in the direction of battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of high expansion rate, poor conductivity, and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

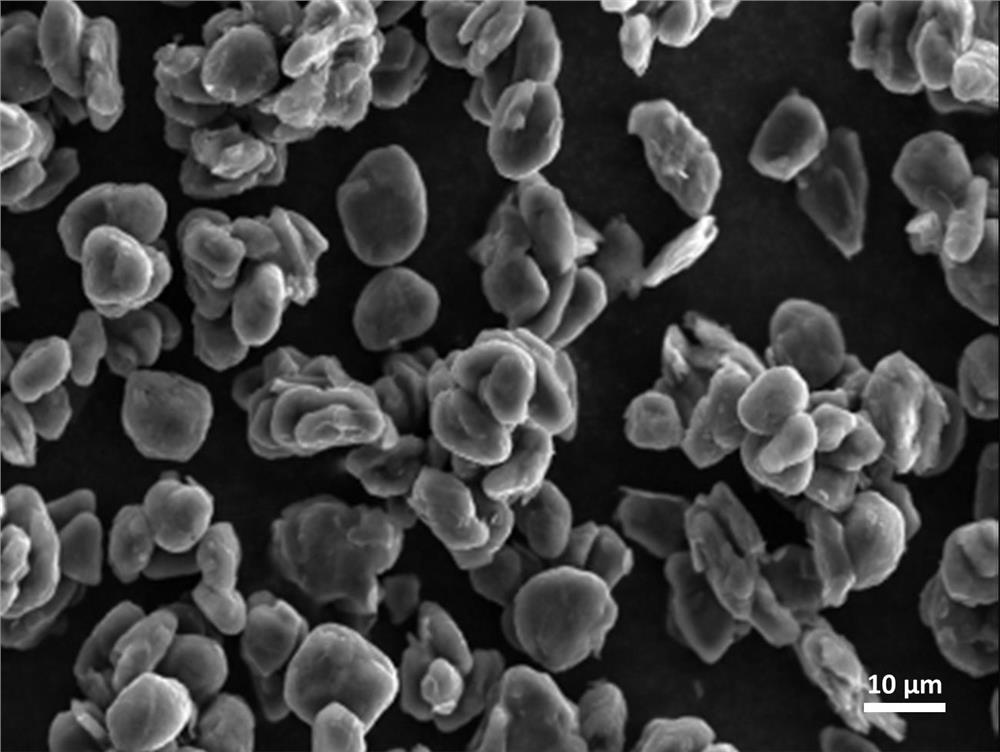

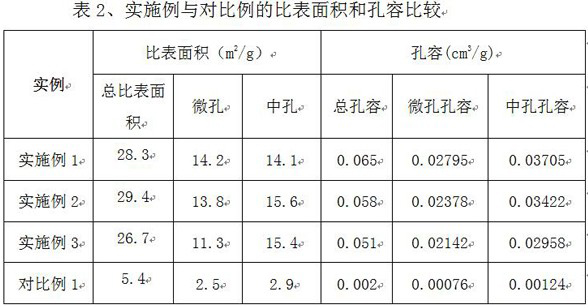

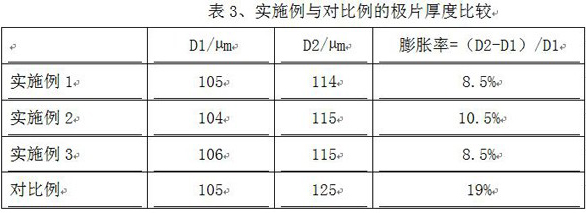

[0025] Mix 100g of silicon monoxide (particle size 5μm) and 5g of nano-nickel (particle size 200nm) into a ball mill, the diameter of the ball is 5mm, the ball-to-material ratio is 8:1, the ball milling speed is 500 rpm, and the ball milling is 24h, to get Silicon monoxide alloy material A; then place silicon monoxide alloy material A in a vacuum heat treatment furnace with a vacuum degree of 0.05 Pa; then heat at a temperature of 1500°C and keep it warm for 5 hours to obtain porous monoxide Silicon material B; naturally cool the porous silicon monoxide material B to 600°C, pass through methane gas and ammonia gas (volume ratio: 100:5), and keep at this temperature for 3 hours, and naturally cool down to room temperature to obtain porous silicon monoxide Silicon composite material C; then weigh 100g of porous silicon monoxide composite material C and 0.5g of inert lithium powder into a ball mill, and ball mill for 6 hours under an argon atmosphere to obtain lithium-replenishing...

Embodiment 2

[0027] Add 100g of silicon monoxide and 1g of nano-aluminum (particle size 100nm) into a ball mill with a ball diameter of 4mm, a ball-to-material ratio of 7:1, a ball milling speed of 500 rpm, and ball milling for 48 hours to obtain a silicon monoxide alloy material A; Afterwards, the silicon monoxide alloy material A is placed in a vacuum heat treatment furnace, and the vacuum degree is kept between 0.1Pa; then heated, and the temperature is kept between 1300°C and kept for 0.1h to obtain a porous silicon monoxide material B; the porous Silicon monoxide material B was naturally cooled to 800°C, acetylene gas and ammonia gas (volume ratio: 100:1) were introduced into it, and kept at this temperature for 1 hour, and then naturally cooled to room temperature to obtain porous silicon monoxide composite material C; Take 100g of porous silicon monoxide composite material C and 0.1g of inert lithium powder and add them to a ball mill, and ball mill for 1 hour under an argon atmosphe...

Embodiment 3

[0029] Add 100g of silicon monoxide and 10g of nano-silver (particle size 500nm) into a ball mill with a ball diameter of 6mm, a ball-to-material ratio of 10:1, a ball milling speed of 600 rpm, and ball milling for 12 hours to obtain a silicon monoxide alloy material A; Then place silicon monoxide alloy material A in a vacuum heat treatment furnace, keep the vacuum degree between 1Pa; then heat, keep the temperature between 1000°C, and keep it warm for 10h to obtain porous silicon monoxide material B; The temperature of silicon material B is naturally cooled to 800°C, and ethane gas and ammonia gas (volume ratio: 100:10) are passed through, and kept at this temperature for 6 hours, and the temperature is naturally cooled to room temperature to obtain porous silicon monoxide composite material C; Add 100g of porous silicon monoxide composite material C and 1g of inert lithium powder into a ball mill, and ball mill for 12 hours under an inert atmosphere to obtain lithium-replenis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com