Preparation method and application of composite magnetic chitosan adsorption material

An adsorption material, chitosan technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of poor adsorption capacity and small number of magnetic chitosan functional groups, etc., and achieve good adsorption capacity , Uniform shape and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] One, the preparation method of composite magnetic chitosan, comprising:

[0027] 1) Preparation of magnetic chitosan

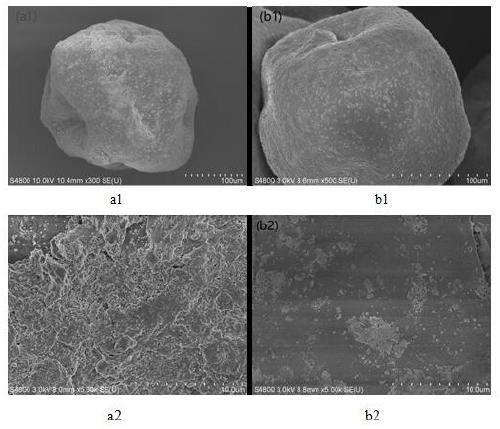

[0028] Dissolve 6g of chitosan and 3g of ferric oxide in 120 mL of 1% acetic acid solution and stir for 12 hours to form a uniform black mixture; add 5 mL of Span 80 to 720 mL of cyclohexane and stir for 1 hour to form a white suspension Slowly add the black mixture into the suspension of Span 80 and cyclohexane under stirring state, raise the temperature to 50°C, then add 3.7 mL of glutaraldehyde with a mass fraction of 50%, react for 1 hour, and use Wash with alcohol for 3 times, then wash with water for 3 times, and dry in vacuum at 60° C. to obtain magnetic chitosan. The scanning electron micrograph of the magnetic chitosan that makes sees figure 1 Middle b1 and b2.

[0029]2) Activation of nitrilotriacetic acid

[0030] Dissolve 1 g of nitrilotriacetic acid into 50 mL of 1% ammonia solution, add 0.5 g of N-hydroxysuccinimide and 0.5 g of 1-ethy...

Embodiment 2

[0050] One, the preparation method of present embodiment graft type magnetic chitosan adsorbent comprises the steps:

[0051] 1) Preparation of magnetic chitosan

[0052] Dissolve 6g of chitosan and 3g of ferric oxide in 120 mL of 1% acetic acid solution, stir for 12 hours to form a uniform black mixture; add 5 mL of Span 80 to 720 mL of cyclohexane, stir for 1 hour to form a white suspension , while stirring, slowly add the black mixture into the suspension of Span 80 and cyclohexane, raise the temperature to 50°C, then add 3.7 mL of glutaraldehyde with a mass fraction of 50%, and react for 1 hour. After the reaction is completed, wash with alcohol Washing for 3 times, then washing with water for 3 times, and vacuum drying at 60° C. to obtain magnetic chitosan.

[0053] 2) Activation of nitrilotriacetic acid

[0054] Dissolve 0.5, 1, 1.2, 1.5, 2 g of nitrilotriacetic acid into 25 mL of ammonia solution with a mass fraction of 1% respectively, record as c, d, e, f, g, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com