Polycarbazole-loaded nano-palladium material as well as preparation method and application thereof

A technology of nano-palladium and polycarbazole, applied in the field of catalytic chemistry, to achieve the effects of green and mild reaction conditions, wide application range and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Pd(OAc) 2 (11.2 mg), carbazole polymer (120 mg) were added to a 100 ml three-necked round bottom flask containing a magnetic stirrer, stirred at room temperature for 30 minutes, and then NaBH was added to it through a syringe 4 (0.05 M, 5.0 mL) aqueous solution, and reacted at room temperature for 4 hours; after the reaction, the solid was separated by centrifugation, washed with water, ethanol and ether in turn, and then vacuum-dried to obtain the corresponding polycarbazole-loaded nano-palladium material (Pd / P3,5-diCzPy).

[0052] ICP analysis indicated that the palladium loading was 1.37% wt.

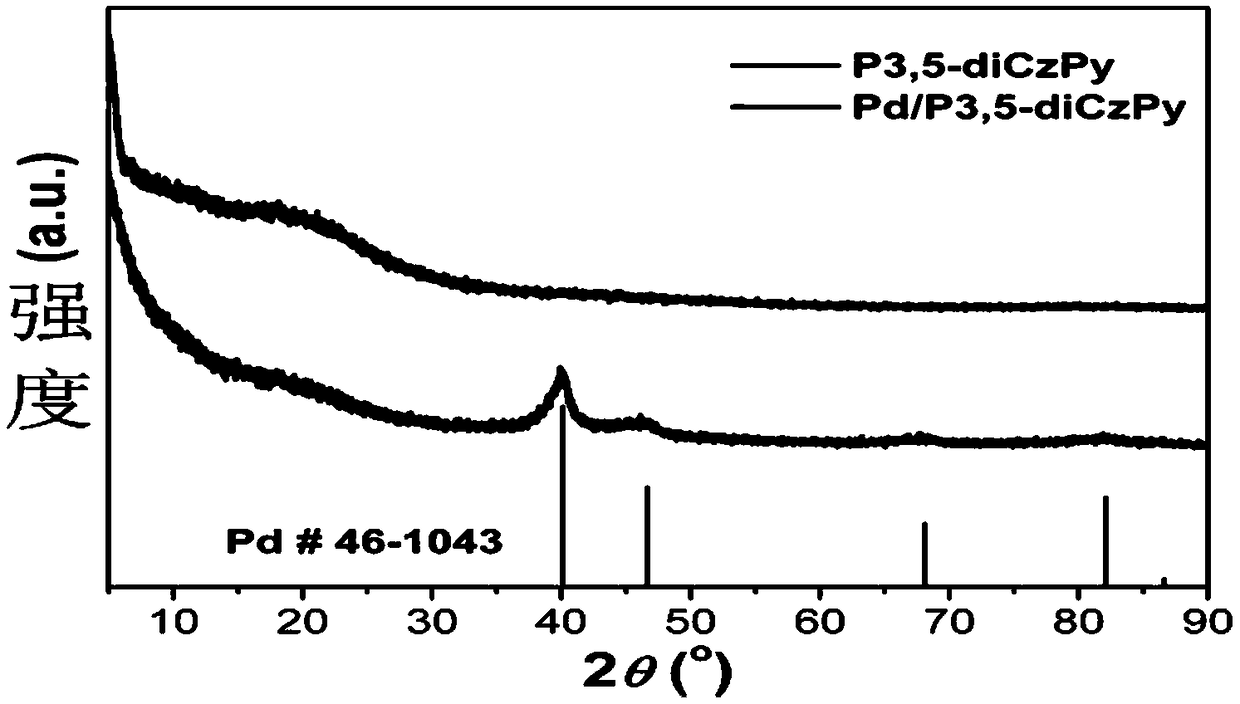

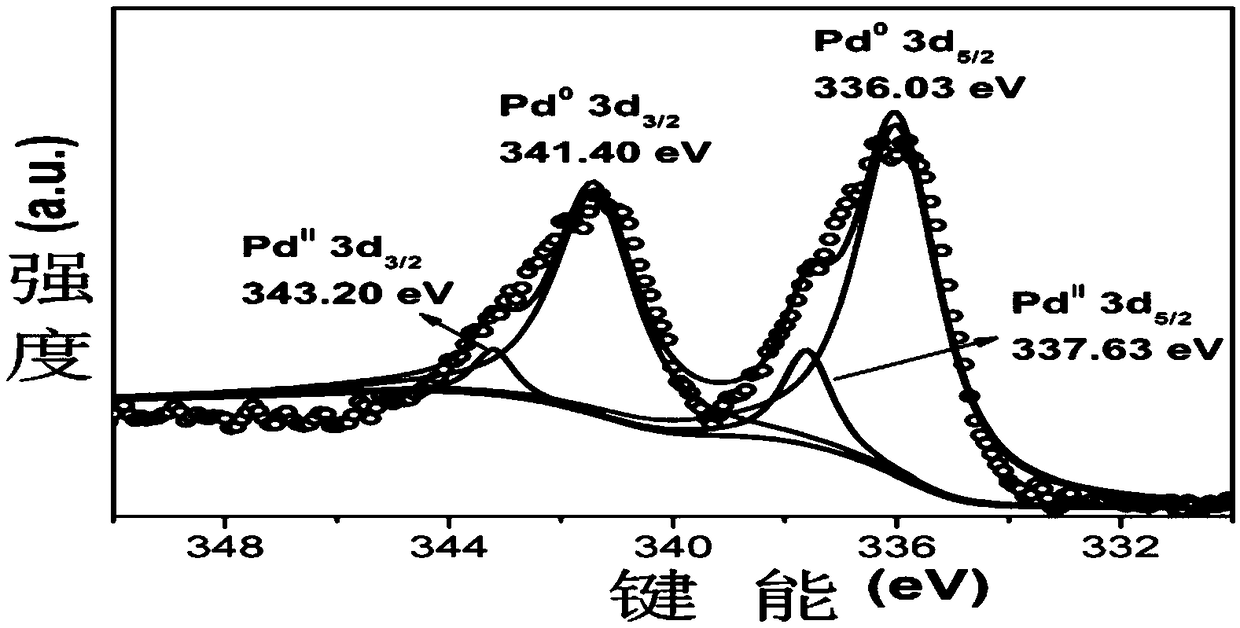

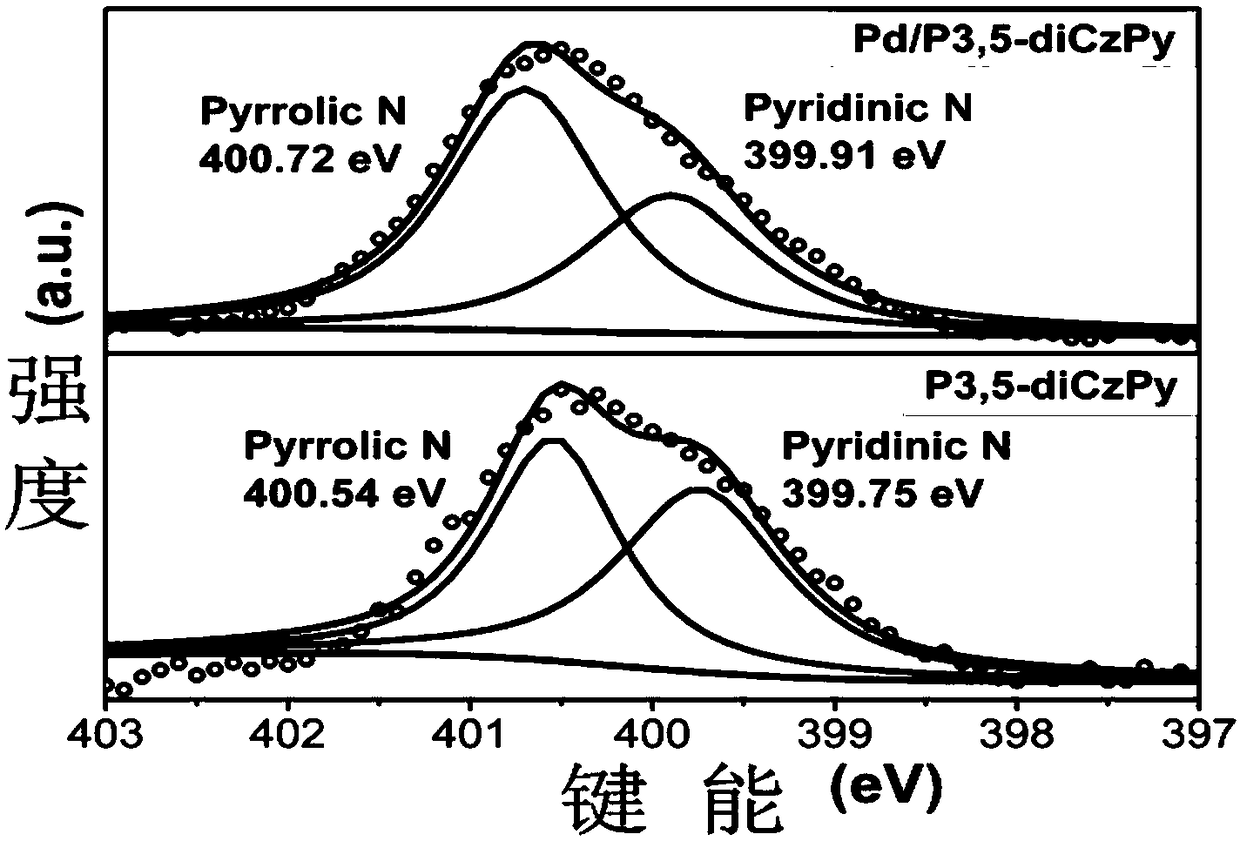

[0053] Figure 1 to Figure 6 Followed by the powder XRD diffraction pattern, photoelectron energy spectrum, transmission electron microscope and particle size distribution, high-resolution transmission electron microscope and element distribution diagram of the palladium nanomaterial supported by the carbazole polymer of the present invention; the powder XRD diffraction pe...

Embodiment 2

[0055]

[0056] Add 4'-bromoacetophenone (40 mg), phenylboronic acid (37 mg), polycarbazole-supported nano-palladium material (8 mg), and potassium phosphate (64 mg) into a 10 ml quartz reaction tube equipped with a magnetic stir bar , add 5 ml of deionized water, repeat three times of liquid nitrogen freezing-pumping-nitrogen-filling-thawing, and then react at room temperature for 12 h under the irradiation of blue light LED; after the reaction, remove the catalyst by filtration, wash the catalyst with ethyl acetate, Extract the filtrate with ethyl acetate, combine the organic phases, dry, filter, concentrate under reduced pressure, and purify by silica gel column chromatography to obtain 4-biphenylethanone (yield 94%); using palladium carbon catalyst, the yield is 12% , adopting palladium chloride yield is 29%.

[0057] The NMR data of the resulting product are as follows:

[0058] 1 H NMR (600 MHz, CDCl 3 ) δ 8.03 (t, J = 6.9 Hz, 2H), 7.68 (dd, J = 7.5,6.3 Hz, 2H)...

Embodiment 3

[0064]

[0065] Add 4'-bromoacetophenone (40 mg), 4-methylphenylboronic acid (41 mg), polycarbazole-loaded nano-palladium material (8 mg), and potassium phosphate (64 mg) to a magnetic stirring bar 10 5 ml of deionized water was added to a quartz reaction tube, and the liquid nitrogen freezing-pumping-nitrogen filling-thawing was repeated three times, and then under the irradiation of a blue LED, the reaction was performed at room temperature for 12 h; after the reaction, the catalyst was removed by filtration, and the acetic acid Wash the catalyst with ethyl acetate, extract the filtrate with ethyl acetate, combine the organic phases, dry, filter, concentrate under reduced pressure, and purify by silica gel column chromatography to obtain 4'-methyl-4-biphenylphenone (98% yield) , if adopting diisopropylamine as the base, the yield is 16%.

[0066] The NMR data of the resulting product are as follows:

[0067] 1 H NMR (400 MHz, CDCl 3 ) δ 7.97 (d, J = 8.1 Hz, 2H), 7.62...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com