Novel bionic affinity purification material and application thereof in purifying chitosanase

A chitosanase and affinity technology, applied in the direction of glycosylation enzymes, biochemical equipment and methods, enzymes, etc., can solve the problems of affecting the biological activity of chitosanase, increasing steps and costs, and achieving low cost, The effect is simple and easy to amplify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

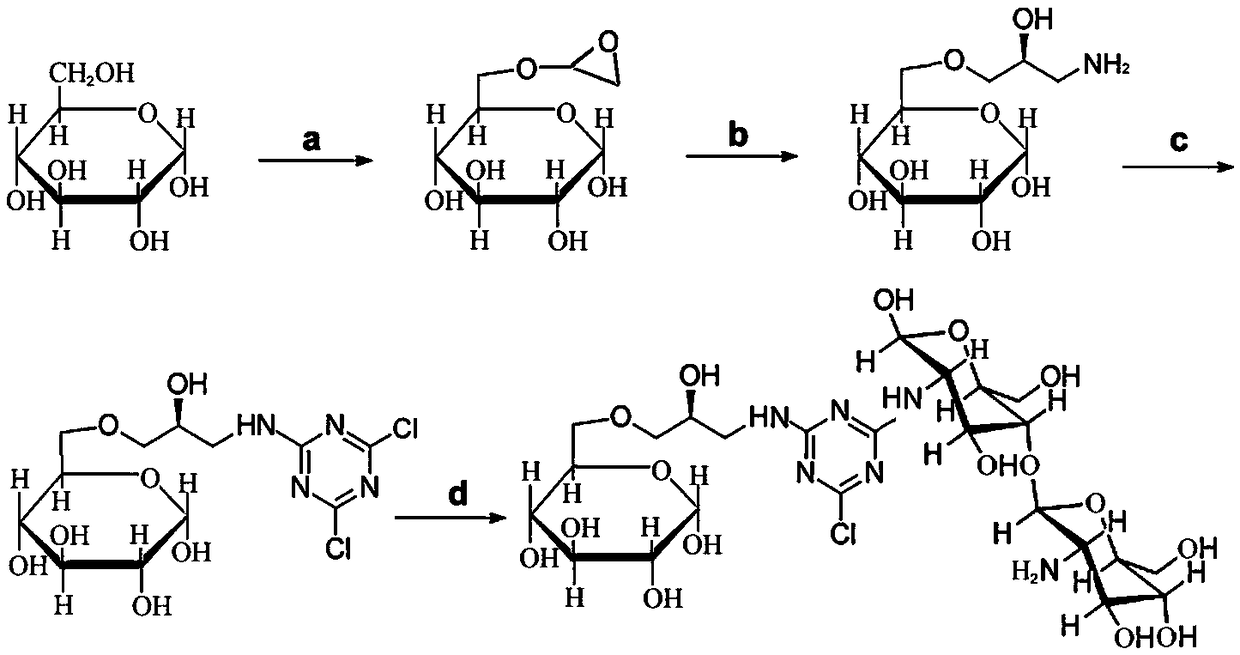

[0022] The synthetic process of embodiment 1 biomimetic affinity material

[0023] The synthesis process of the biomimetic affinity material includes 4 steps: 1), epichlorohydrin activates the agarose gel, makes the agarose gel in an activated state to connect other groups; 2), amination of the agarose gel, Add amino groups to the activated agarose gel; 3), connect the cyanuric chloride connecting arm, and use the connected amino group to crosslink the cyanuric chloride connecting arm; 4), chelate chitobiose biomimetic affinity ligand, and connect Chitobiose biomimetic affinity ligand coupled to the arm. Specific steps are as follows:

[0024] 1.1 Epichlorohydrin activated agarose gel

[0025] The agarose gel (Sepharose 6B) was thoroughly washed with double distilled water at a ratio of 1:10 (v / v), so that the pH of the effluent was balanced to 7.0, and the washed agarose gel was dried at room temperature and dissolved In 100mL activation solution (1M sodium hydroxide, 2.5g...

Embodiment 2

[0032] Performance characterization of embodiment 2 biomimetic affinity material

[0033] The biomimetic affinity material synthesized in Example 1 is a macromolecular biomimetic affinity gel. In order to determine the ligand density of the synthesized biomimetic affinity material, the biomimetic affinity material synthesized in step 1.2 in Example 1 was used to The ketone method was used to detect the amino group density in the biomimetic affinity material, so as to characterize the ligand density of the synthesized biomimetic affinity material. The density of the synthesized biomimetic affinity ligand was found to be 20.9 μmol / ml by ninhydrin method.

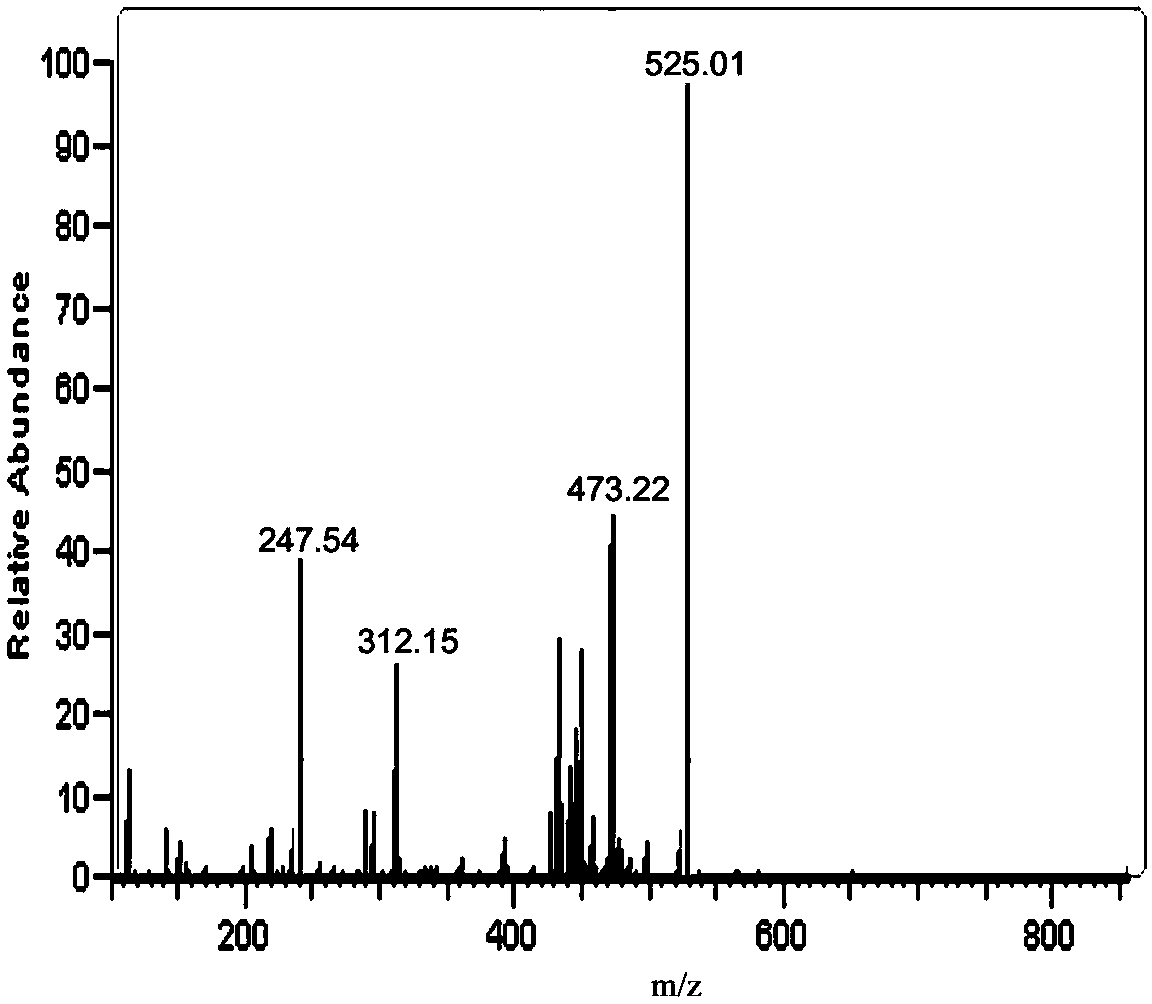

[0034] In order to determine the structure of the bionic affinity ligand in the synthesized biomimetic affinity material, the synthesized biomimetic affinity gel was added into 6M concentrated hydrochloric acid in equal proportions (w / v), and after 6 hours of action, it was centrifuged at 4000rpm for 10min, and the supernatant...

Embodiment 3

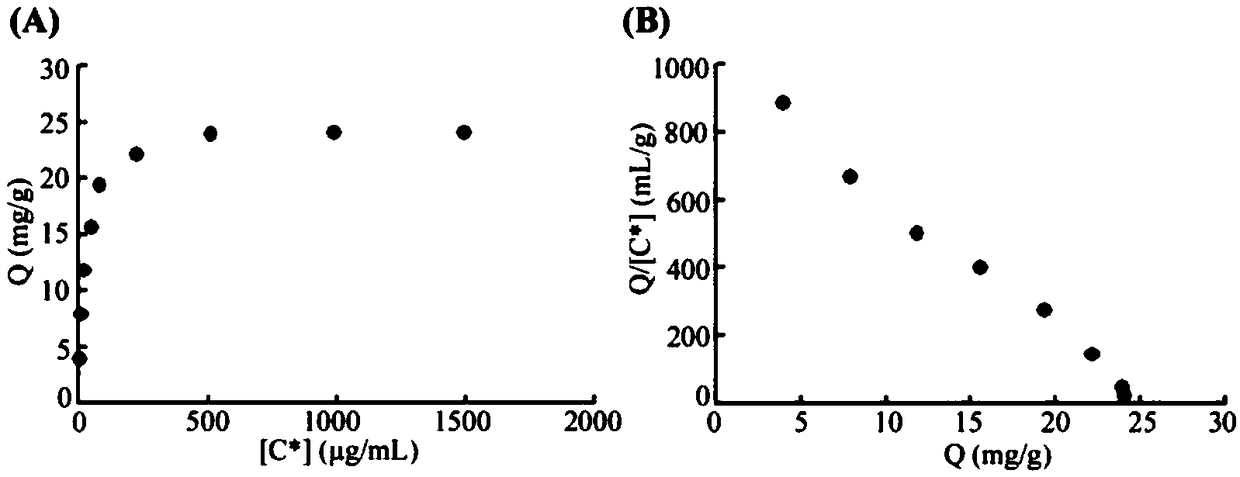

[0035] Example 3 Dissociation constant and maximum binding capacity of biomimetic affinity material

[0036] Utilize Scatchard (Scatchard) equation method to carry out dissociation constant (K d ) and maximum binding capacity (Q max ) evaluation to determine the adsorption and dissociation abilities of the synthesized biomimetic affinity material to chitosanase CsnM. The chitosanase CsnM used was purchased from Qingdao Aifite Biotechnology Co., Ltd.

[0037] The specific assay method is: take 1 mL of chitosanase CsnM with different concentrations (0.1-0.9 mg / mL, 20 mM Gly-NaOH, pH 8.6) and mix it with 0.5 g of the biomimetic affinity material described in Example 1, and mix it at 4° C. Under the condition of 100rpm shaking culture for 2h, to reach the adsorption equilibrium. The mixture was centrifuged at 1500 g for 5 min, and the remaining protease activity and protein content in the supernatant were detected. The detected data is calculated according to the Scatchard equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com