Reactive dye wastewater treatment method and device

A reactive dye and wastewater treatment technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of reduced electrocoagulation treatment efficiency and impact on wastewater treatment effect, and achieves Improve catalytic activity and durability, promote oxidation precipitation, and improve the effect of decolorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

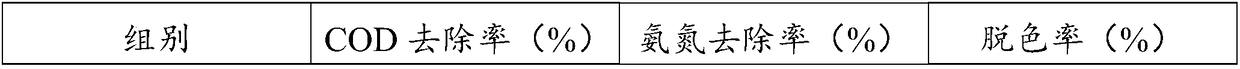

Examples

Embodiment 7

[0026] The actual dye wastewater used in Example 7 is taken from the wastewater receiving pond of a certain printing and dyeing enterprise in Jiangmen. It is a mixed wastewater of various dye wastewater, mainly reactive dyes, pH is 5-7, COD is 7558mg / L, and ammonia nitrogen is 67.2mg / L.

[0027] The following examples adopt the electrolyte as a concentration of 0.05-0.06M Na 2 SO 4 solution.

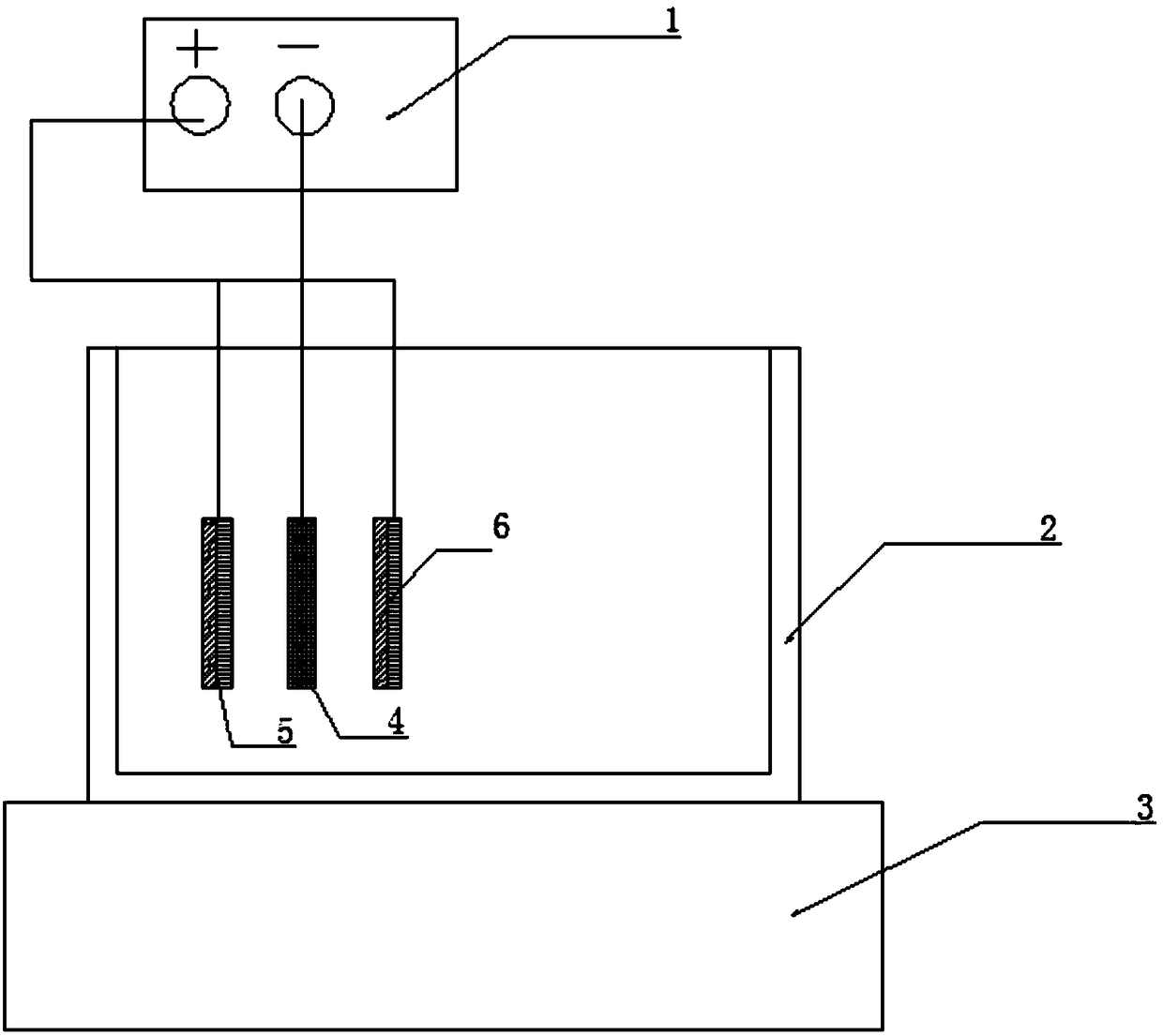

[0028] The following examples adopt self-made reactive dye wastewater treatment device, such as figure 1 As shown, it includes a power supply, electrodes, an electrolytic cell and an ultrasonic generator, and the electrodes include a first anode electrode, a cathode electrode and a second anode electrode, and the first anode electrode and the second anode electrode are both aluminum-titanium composite electrodes , the aluminum-titanium composite electrode is composed of a titanium electrode and an aluminum electrode coated with an electrochemical catalyst on the surface, the cathode ...

Embodiment 1

[0030] A kind of reactive dye wastewater treatment method, comprises the following steps:

[0031] (1) introducing reactive dye wastewater into the electrolyzer, adding electrolyte, and adjusting the pH of reactive dye wastewater to be 5.5;

[0032](2) Select an aluminum-titanium composite electrode composed of an aluminum electrode and a titanium electrode as the anode, and the surface of the titanium electrode is coated with an electrochemical catalyst, use an iron electrode as the cathode, and control the electrode voltage to 12V. Under ultrasonic conditions, the ultrasonic power The ultrasonic frequency is 600W, the ultrasonic frequency is 90kHz, the electrolytic treatment is 5h, and the treated water is discharged, wherein the electrochemical catalyst includes ruthenium oxide and biochar, and the mass ratio of ruthenium oxide and biochar is 0.1:1.

[0033] Among them, the aluminum electrode is soaked in acetone solution for 5 minutes before use, polished with sandpaper, a...

Embodiment 2

[0038] A kind of reactive dye wastewater treatment method, comprises the following steps:

[0039] (1) introducing reactive dye wastewater into the electrolyzer, adding electrolyte, and adjusting the pH of reactive dye wastewater to be 5.5;

[0040] (2) Select an aluminum-titanium composite electrode composed of an aluminum electrode and a titanium electrode as the anode, and the surface of the titanium electrode is coated with an electrochemical catalyst, use an iron electrode as the cathode, and control the electrode voltage to 12V. Under ultrasonic conditions, the ultrasonic power It is 600W, the ultrasonic frequency is 90kHz, the electrolysis treatment is 5h, and the treated water is discharged, wherein, the electrochemical catalyst includes ruthenium oxide and biochar, and the mass ratio of ruthenium oxide and biochar is 0.16:1.

[0041] Among them, the aluminum electrode is soaked in acetone solution for 5 minutes before use, polished with sandpaper, and placed in 0.5M s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap