Zirconia ceramic bone implant and preparation method thereof

A technology of zirconia ceramics and bone implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

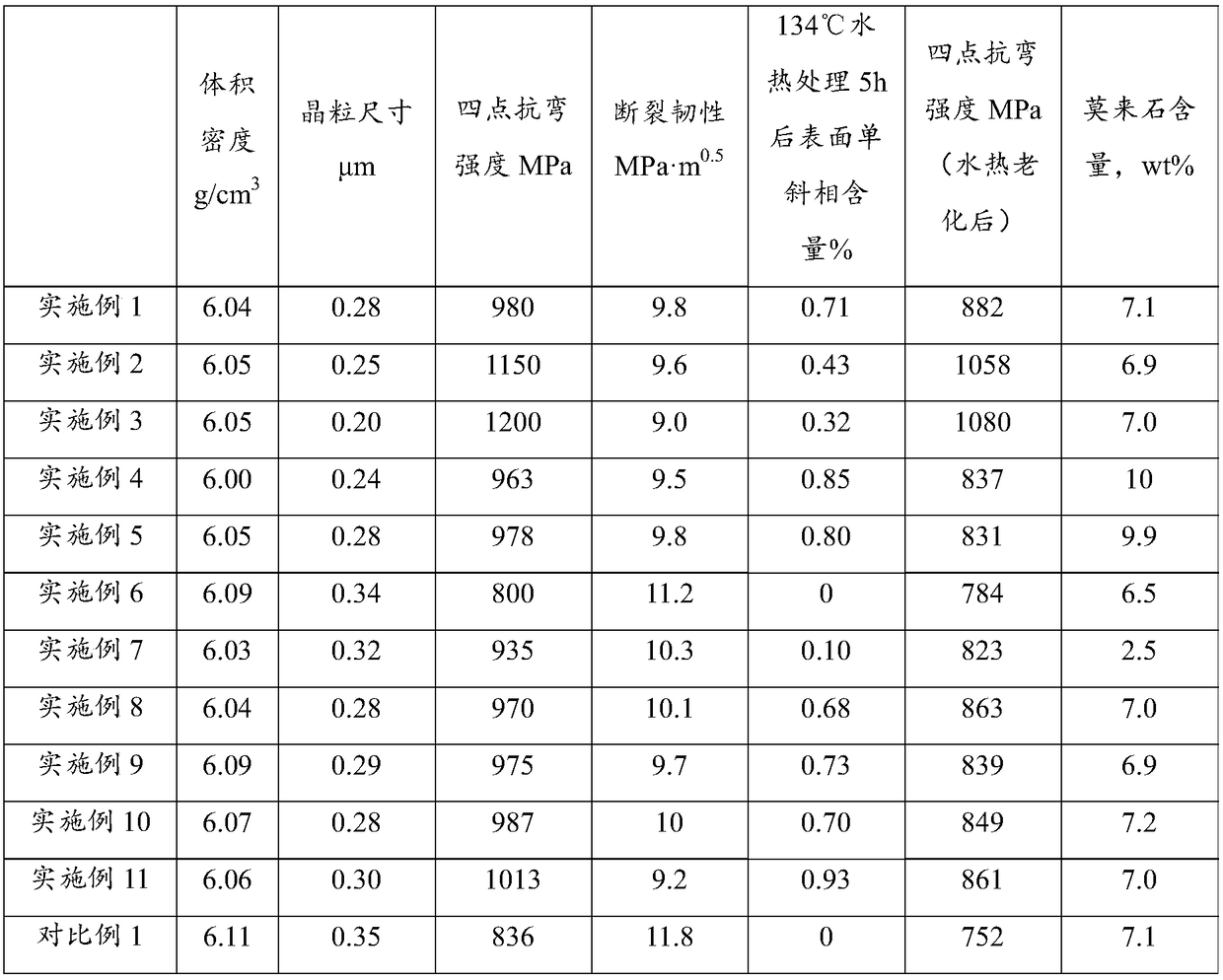

Examples

Embodiment 1

[0058] The first step, mixing zirconia powder, stabilizer A, acidic silica sol (concentration: 10wt%) and aluminum sol (concentration: 10wt%), wet grinding for 30h to obtain slurry; based on the weight of zirconia powder , the addition of stabilizer A, acidic silica sol (calculated as silica), and aluminum sol (calculated as alumina) are respectively 5%, 3%, and 7.5%; stabilizer A is yttrium oxide, and the particle size is ≤5 μm; The purity of zirconia fine powder is: ZrO 2 +HfO 2 ≥99.9wt%, particle size ≤74μm;

[0059] In the second step, water is added to the slurry, mixed evenly, and spray-dried to obtain particles;

[0060] The third step is to cool the particles in the mold at 250MPa to obtain a green body;

[0061] Step 4: After drying the green body, heat it at 1000°C for 5 hours to complete the pre-calcination to obtain the green body;

[0062] The fifth step is to sinter the biscuit in a microwave sintering furnace at 1200° C. for 1 hour to obtain zirconia ceramic...

Embodiment 2

[0064] The difference from Example 1 is that the amount of stabilizer A added is different, specifically as follows.

[0065] The first step, mixing zirconia powder, stabilizer A, acidic silica sol (concentration: 10wt%) and aluminum sol (concentration: 10wt%), wet grinding for 30h to obtain slurry; based on the weight of zirconia powder , the addition of stabilizer A, acidic silica sol (calculated as silica), and aluminum sol (calculated as alumina) are respectively 8%, 3%, and 7.5%; stabilizer A is yttrium oxide, and the particle size is ≤5 μm; The purity of zirconia fine powder is: ZrO 2 +HfO 2 ≥99.9wt%, particle size ≤74μm;

[0066] In the second step, water is added to the slurry, mixed evenly, and spray-dried to obtain particles;

[0067] The third step is to cool the particles in the mold at 250MPa to obtain a green body;

[0068] Step 4: After drying the green body, heat it at 1000°C for 5 hours to complete the pre-calcination to obtain the green body;

[0069] Th...

Embodiment 3

[0071] The difference from Example 1 is that the amount of stabilizer A added is different, specifically as follows.

[0072] The first step, mix zirconia powder, stabilizer A, acidic silica sol (calculated as silicon dioxide), and aluminum sol (calculated as alumina), and wet grind for 30 hours to obtain slurry; the weight of zirconia powder is Benchmark, the addition amount of stabilizer A and acidic silica sol (calculated as silica) is 10%, 3%, 7.5% respectively; stabilizer A is yttrium oxide, particle size ≤ 5 μm; zirconia fine powder purity: ZrO 2 +HfO 2 ≥99.9wt%, particle size ≤74μm;

[0073] In the second step, water is added to the slurry, mixed evenly, and spray-dried to obtain particles;

[0074] The third step is to cool the particles in the mold at 250MPa to obtain a green body;

[0075] Step 4: After drying the green body, heat it at 1000°C for 5 hours to complete the pre-calcination to obtain the green body;

[0076] The fifth step is to sinter the biscuit in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com