Method for synthesizing lithium sulfide/carbon composite material and lithium-sulfur battery using material

A technology of carbon composite materials and lithium sulfide, applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low Li2S content in the composite, complicated preparation process, poor dissolution and conductivity, etc., and achieve easy realization and promotion, the preparation process and equipment are simple, and the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

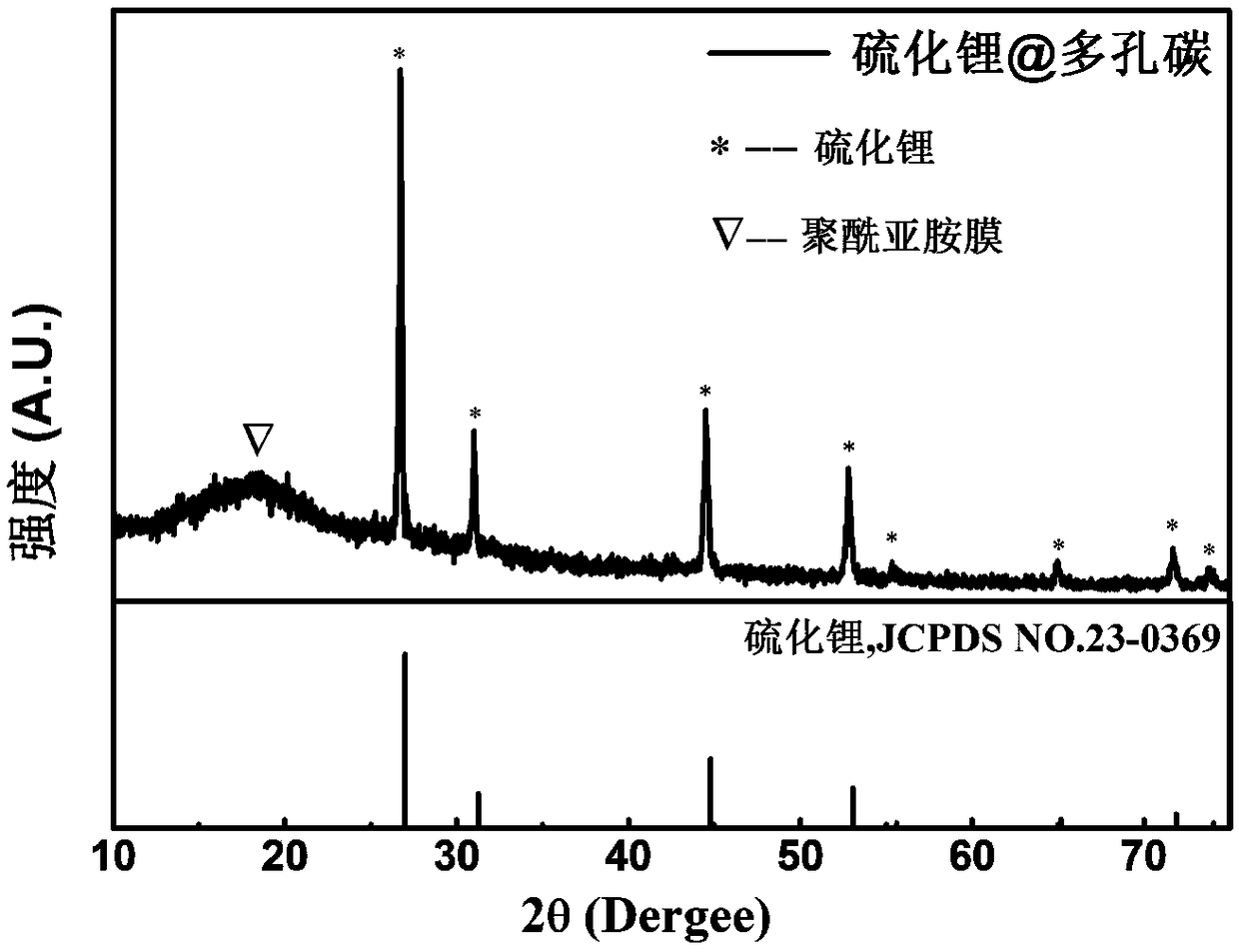

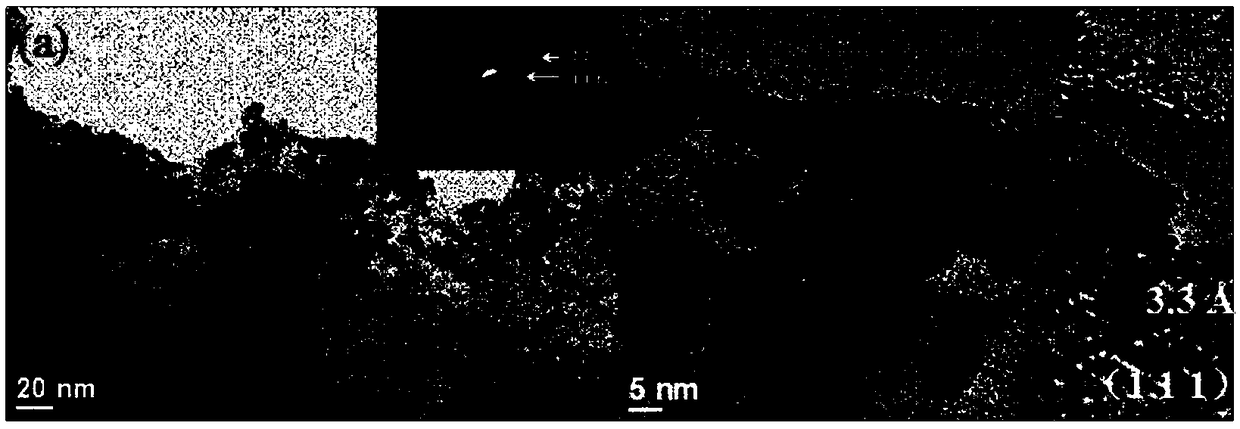

[0021] Prepare an aqueous solution of lithium sulfate monohydrate and glucose at a molar ratio of 2:1, heat and stir in a water bath at 80°C, then heat and dry in an oven at 80°C, and grind it into powder. Place the obtained powder in the constant temperature zone of the tube furnace, raise the temperature to 600°C at 10°C / min under 200ml / min argon atmosphere, keep it for 2h, then raise the temperature to 800°C at 10°C / min, keep it for 2h, The temperature was lowered to 350 °C at a rate of 10 °C / min in an air-protected atmosphere, and then cooled to room temperature with the furnace to obtain a lithium sulfide@porous carbon composite. attached figure 1 For the X-ray diffraction analysis of the lithium sulfide@porous carbon composite, it was determined that a pure phase of lithium sulfide was obtained. attached figure 2 Its high-power transmission electron microscope image shows that nano-scale lithium sulfide particles are evenly distributed in the carbon skeleton, and the ...

Embodiment 2

[0024] Prepare an aqueous solution of lithium sulfate monohydrate and glucose at a molar ratio of 1:1, heat and stir in a water bath at 80°C, then heat and dry in an oven at 80°C, and grind it into powder. Place the obtained powder in the constant temperature zone of the tube furnace, raise the temperature to 600°C at 10°C / min under 200ml / min argon atmosphere, keep it for 2h, then raise the temperature to 800°C at 10°C / min, keep it for 2h, The temperature was lowered to 350 °C at a rate of 10 °C / min in an air-protected atmosphere, and then cooled to room temperature with the furnace to obtain a lithium sulfide@porous carbon composite.

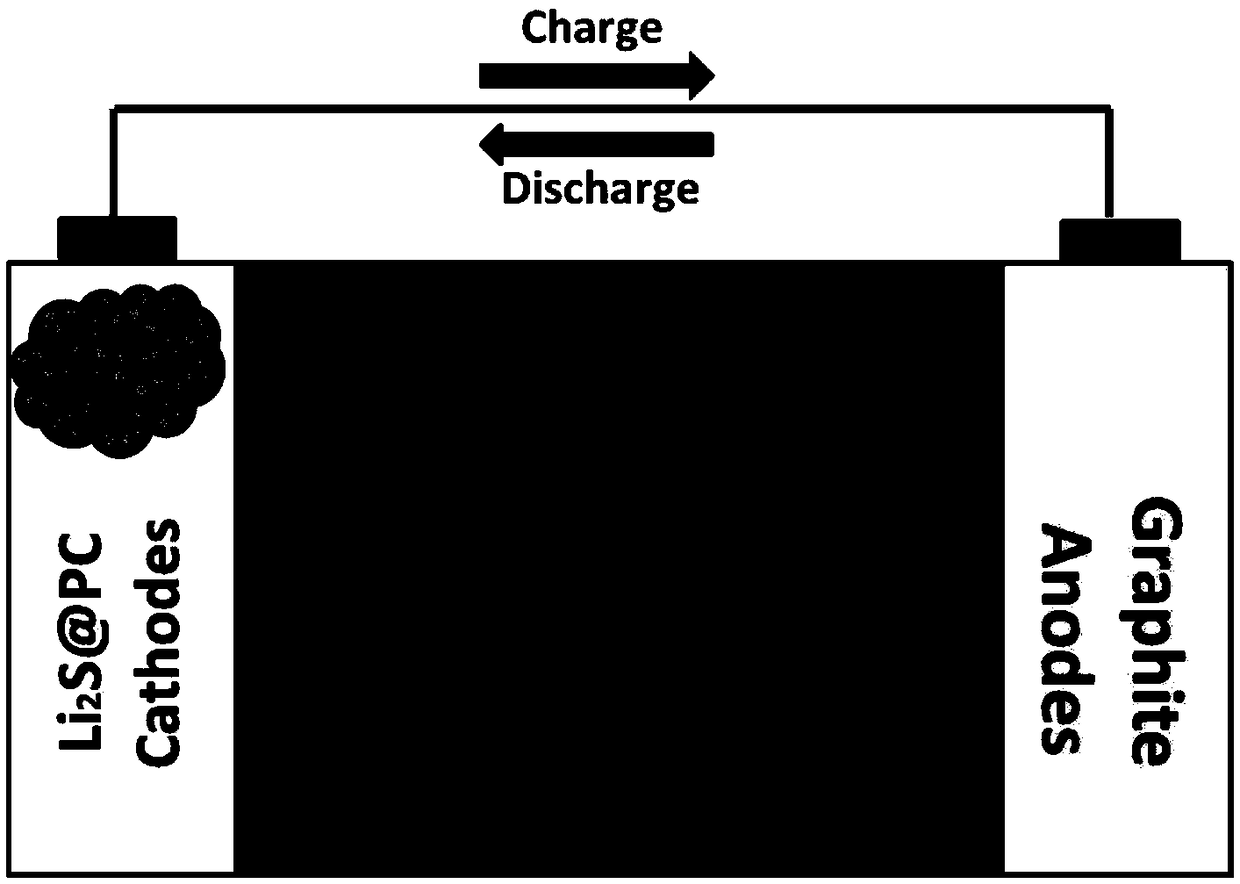

[0025] Match the capacity of positive and negative electrodes according to the ratio of 1.3:1 to assemble the battery. Put the installed battery on hold for 24 hours and then carry out the charge and discharge test: first use constant voltage (1.5V) to charge until the current value is less than 0.02C to stop, then use 0.05C to carry out consta...

Embodiment 3

[0027] Prepare an aqueous solution of lithium sulfate monohydrate and citric acid at a molar ratio of 2:1, heat and stir in a water bath at 80°C, then heat and dry in an oven at 80°C, and grind it into powder. Place the obtained powder in the constant temperature zone of the tube furnace, raise the temperature to 600°C at 10°C / min under 200ml / min argon atmosphere, keep it for 2h, then raise the temperature to 800°C at 10°C / min, keep it for 2h, The temperature was lowered to 350 °C at a rate of 10 °C / min in an air-protected atmosphere, and then cooled to room temperature with the furnace to obtain a lithium sulfide@porous carbon composite.

[0028] Match the capacity of positive and negative electrodes according to the ratio of 1.3:1 to assemble the battery. Put the installed battery on hold for 24 hours and then conduct a charge and discharge test: first use constant voltage (2V) to charge until the current value is less than 0.02C to stop, then use a current of 0.05C to carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com