A kind of self-crosslinking type vinyl chloride copolymer emulsion and preparation method thereof

A vinyl chloride copolymerization and self-crosslinking technology, which is applied in coatings, anti-corrosion coatings, etc., can solve problems such as poor chemical resistance, unsatisfactory hydrolytic stability of formulated varnishes and paints, and hazards to human health and the natural environment , to achieve the effect of improving high temperature resistance, ensuring storage stability, and avoiding the phenomenon of anti-coarseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

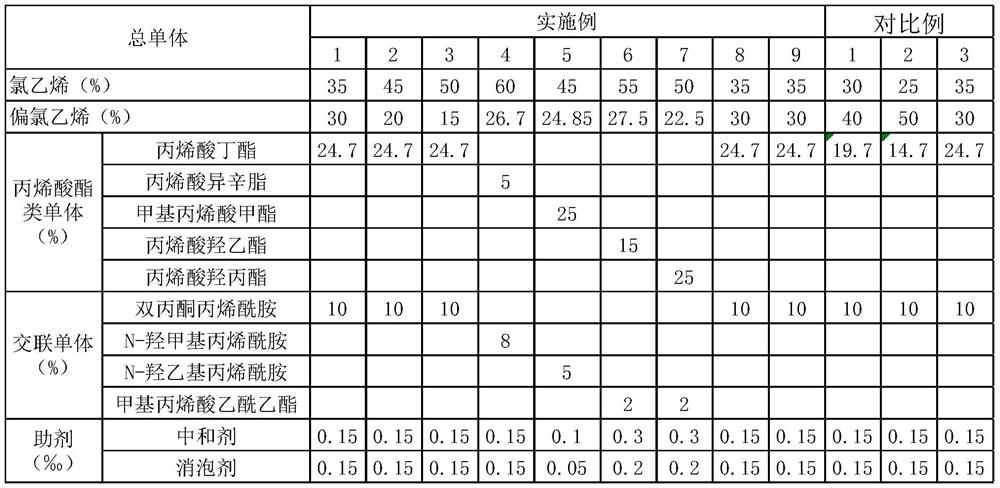

[0031] 1. Total monomer embodiment

[0032]

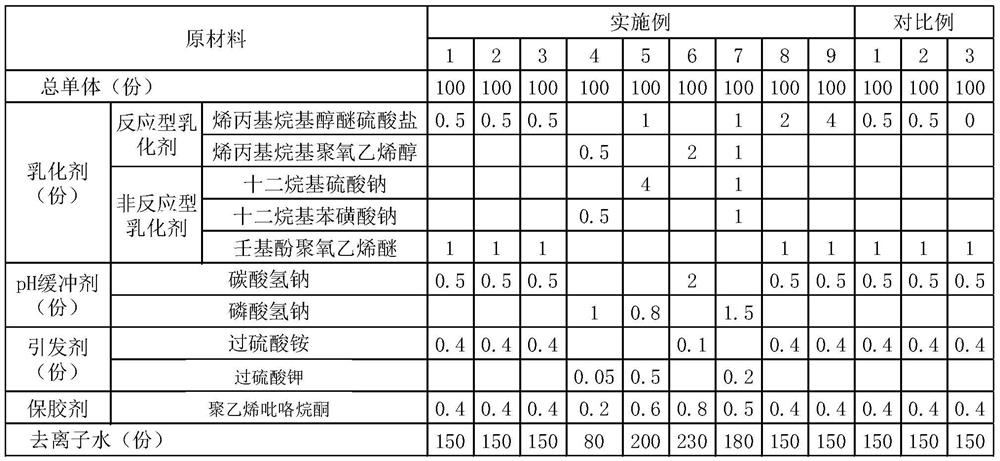

[0033] 2. Example of Self-crosslinking Vinyl Chloride Copolymer Emulsion

[0034]

[0035] 3. Embodiment 1-9 and comparative example 1-3 are prepared according to the following method self-crosslinking type vinyl chloride copolymer emulsion, and its specific steps are as follows:

[0036] (1) monomer pre-emulsification

[0037] Weigh vinyl chloride, vinylidene chloride, acrylate, cross-linking monomer, and non-reactive emulsifier, put them into a pre-emulsification tank, and stir and emulsify for 1 hour at a stirring speed of not less than 200r / min to obtain pre-emulsified Monomer solution;

[0038] (2) Preparation and addition of additives: Take 70-160 parts of deionized water, reactive emulsifier, pH buffer, and glue-preserving agent, stir and dissolve fully, then add to step (1) pre-emulsification kettle; take initiator and dissolve in 10 -80 parts of water for standby;

[0039] (3) Reaction: by volume, first take 1 / 5 ...

preparation example 1

[0055] (1) monomer pre-emulsification

[0056] The total number of monomers is 100 parts, weigh 35% of vinyl chloride, 30% of vinylidene chloride, 24.7% of butyl acrylate, 10% of diacetone acrylamide, and 1 part of nonylphenol polyoxyethylene ether, and put them into the pre-emulsification kettle , under the condition that the stirring speed is 200r / min, stir and emulsify for 1h to obtain a pre-emulsified monomer solution;

[0057] (2) Preparation and addition of additives: Take 120 parts of deionized water, 0.5 part of allyl alkyl alcohol ether sulfate, 0.5 part of sodium bicarbonate, and 0.4 part of polyvinylpyrrolidone, stir and dissolve and then add the step ( 1) in the pre-emulsification kettle; get ammonium persulfate and dissolve it in 30 parts of water for subsequent use;

[0058] (3) Reaction: by volume, first take 1 / 5 of the pre-emulsified monomer in step (1) in the polymerization kettle, stir for 30-50 minutes and then heat up to 75±1°C, then add the dissolved mono...

preparation example 2

[0060] Others are the same as Preparation Example 1, except that the stirring speed in step (1) is 180r / min. Its vinyl chloride conversion rate is 97.2%, the emulsion particle size is 0.1-0.25μm, and the average molecular weight is 17.6×10 4 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com