Method for preparing fuel cell polar plate through 3D printing

A fuel cell plate and 3D printing technology, applied in fuel cells, 3D object support structures, circuits, etc., can solve the problems of difficult processing, low melting temperature of raw materials, poor conductivity, etc., and achieve yield and cost advantages, glass transition temperature The effect of high temperature and high softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

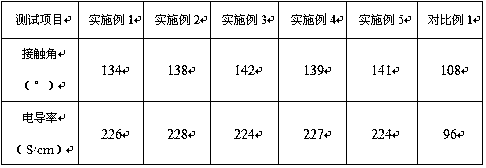

Examples

Embodiment 1

[0030] a. Add nano-alloy powder into dichloromethane solvent, stir and sonicate. The ultrasonic power density of sonication is 1.2W / cm 2 , the time is 25min, the stirring speed is 150r / min, and the heating temperature is 55°C; the alloy powder is uniformly dispersed, then polylactic acid and glass fiber are added, and the stirring is continued for 30min, and Tween 20 is further added as an emulsifier, and carried out under stirring. Heating until the solvent is completely volatilized to obtain a solid jelly; wherein, the metal elements in the nano-alloy powder include iron, cobalt, polylactic acid, nano-alloy powder, and glass fiber in a mass ratio of 100:5:1;

[0031] b. Place the solid jelly obtained in step a in a vacuum oven for low-temperature heat treatment. The temperature of the heat treatment is 75° C., and the time is 90 minutes. Then, ball milling, granulation, and wire drawing are performed. The ratio is 6:1, and the time is 14h; the core-shell structure formed by ...

Embodiment 2

[0034] a. Add nano-alloy powder into dichloromethane solvent, stir and sonicate. The ultrasonic power density of sonication is 1.4W / cm 2 , the time is 22min, the stirring speed is 180r / min, and the heating temperature is 57°C; the alloy powder is evenly dispersed, then polylactic acid and glass fiber are added, and the stirring is continued for 30min, and Tween 20 is further added as an emulsifier, and it is carried out under stirring. Heating until the solvent is completely volatilized to obtain a solid jelly; wherein, the metal elements in the nano-alloy powder include nickel, aluminum, polylactic acid, nano-alloy powder, and glass fiber in a mass ratio of 100:5:1;

[0035]b. Place the solid jelly obtained in step a in a vacuum oven for low-temperature heat treatment. The temperature of the heat treatment is 78° C. and the time is 80 minutes. Then ball milling, granulation, and wire drawing are performed. The rotating speed of the ball milling is 450r / min. The ratio is 7:1, ...

Embodiment 3

[0038] a. Add nano-alloy powder into dichloromethane solvent, stir and sonicate. The ultrasonic power density of sonication is 1.6W / cm 2 , the time is 20min, the stirring speed is 200r / min, and the heating temperature is 60°C; the alloy powder is uniformly dispersed, then polylactic acid and glass fiber are added, and the stirring is continued for 30min, and Tween 20 is further added as an emulsifier, and carried out under stirring. Heating until the solvent is completely volatilized to obtain a solid jelly; wherein, the metal elements in the nano-alloy powder include copper, zirconium, polylactic acid, nano-alloy powder, and glass fiber in a mass ratio of 100:5:1;

[0039] b. Place the solid jelly obtained in step a in a vacuum oven for low-temperature heat treatment. The temperature of the heat treatment is 80° C. and the time is 60 minutes. Then ball milling, granulation, and wire drawing are performed. The ratio is 8:1, and the time is 12 hours to prepare the core-shell st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com