Super-hydrophilic oleophobic material, preparation method and applications thereof

A super-hydrophilic and oleophobic technology, applied in separation methods, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of poor chemical and thermal stability of organic polymer materials, high-viscosity oil anti-sticking Solve problems such as poor adhesion and separation limitations, and achieve fast and efficient separation performance, strong resistance to oil adhesion and pollution, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In some more specific embodiments, the preparation method of the superhydrophilic and oleophobic material comprises:

[0037] Provide metal substrate;

[0038] immersing the metal substrate in a phosphate solution containing 0.1-10 mol / L phosphate and 0.01-1 mol / L oxidizing agent for 0.5-6 hours, and the reaction temperature is 20-60°C to obtain the Said superhydrophilic and oleophobic materials,

[0039] Alternatively, the metal substrate and the cathode as the anode are placed in a phosphate solution with a concentration of 0.1 to 10 mol / L, and the potential difference between the cathode and the anode is 0.1 to 10V, and the reaction is performed for 10 minutes to 2 hours to prepare Obtain the superhydrophilic and oleophobic material.

[0040] More preferably, the oxidizing agent may be hydrogen peroxide, potassium persulfate, sodium persulfate, ammonium persulfate, etc., but not limited thereto.

[0041] More preferably, the phosphate includes any one or a combina...

Embodiment 1

[0110] (1) The 400-mesh copper mesh was respectively immersed in deionized water, ethanol and 0.1M hydrochloric acid solution for ultrasonic cleaning, then washed with deionized water and dried naturally.

[0111] (2) At room temperature, add 500 mL of water, 7.05 g of disodium hydrogen phosphate and 1.35 g of potassium persulfate into a beaker, stir and mix evenly to prepare a uniform reaction solution.

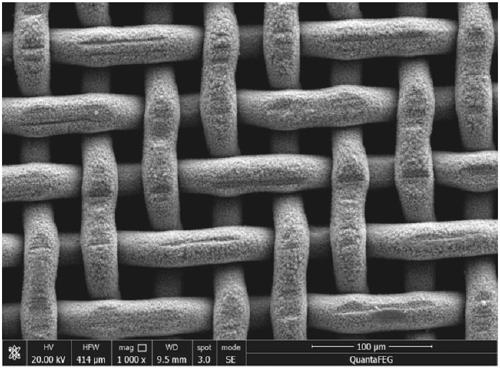

[0112] (3) soak the pre-cleaned copper mesh in step (1) in the solution to react, and the reaction time is 1 hour, so that the copper phosphate nanosheets are evenly coated on the surface of the copper mesh, and the omentum is taken out after the reaction is completed. Wash it repeatedly with deionized water, and dry it naturally in the air to obtain an oil-water separation omentum with super-hydrophilic and super-oleophobic properties in the air environment and underwater. The pore size of the omentum is about 20-25mm. microns, for surface topography see figure 1 .

[011...

Embodiment 2

[0117] (1) Dip the 20-mesh stainless steel mesh into deionized water and ethanol for ultrasonic cleaning, then wash it with deionized water and dry it naturally.

[0118] (2) At room temperature, add 500 mL of water, 23.4 grams of sodium dihydrogen phosphate, 88.6 grams of disodium hydrogen phosphate dodecahydrate, and 9.32 grams of ammonium persulfate, stir and mix evenly to prepare a uniform aqueous solution.

[0119] (3) Soak the pre-cleaned stainless steel net in step (1) in the solution to react, and the reaction time is 0.5 hour, thereby forming copper phosphate nanosheets covering the metal net on the surface of the metal net, and the length height of the nanosheet is about Take out the omentum after the reaction is completed, wash it repeatedly with deionized water, and dry it naturally in the air to obtain oil-water with super-hydrophilic and super-oleophobic properties in the air environment and underwater. Separate the omentum, the pore size of the omentum is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com