Environment-friendly high-strength UV adhesive

A high-strength, environmentally friendly technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of insufficient bonding strength and limit the use of UV-curable adhesives, achieving good thixotropy and low cost. , the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An environment-friendly high-strength UV glue, comprising the following raw materials by weight: 30 parts of epoxy acrylate, 30 parts of modified polyurethane acrylate, 5 parts of honey, 7 parts of viscosity enhancer, 22 parts of photoinitiator, anti-aging 18 parts of agent, 6 parts of polyvinyl alcohol, 4 parts of dibutyl phthalate, 2 parts of silicon micropowder, 3 parts of sodium pyrophosphate, 2 parts of fragrance, 12 parts of xanthan gum; the viscosity enhancer is polyurethane; The photoinitiator is 2-hydroxyl-2-methyl-1-phenylacetone; the antiaging agent is UV327; the spice is menthol glucoside.

[0024] Among them, sodium pyrophosphate has the properties of emulsifying, dispersing, preventing fat oxidation, and improving protein binding; polyvinyl alcohol has unique strong adhesion, film flexibility, smoothness, oil resistance, solvent resistance, Protective colloid, gas barrier, abrasion resistance and water resistance after special treatment; dibutyl phthalate ...

Embodiment 2

[0029] An environment-friendly high-strength UV glue, comprising the following raw materials in parts by weight: 45 parts of epoxy acrylate, 45 parts of modified polyurethane acrylate, 10 parts of honey, 12 parts of viscosity enhancer, 28 parts of photoinitiator, anti-aging 26 parts of agent, 10 parts of polyvinyl alcohol, 8 parts of dibutyl phthalate, 5 parts of silicon micropowder, 5 parts of sodium pyrophosphate, 4 parts of fragrance, 18 parts of xanthan gum; the viscosity enhancer is polystyrene ; The photoinitiator is 2,4,6-trimethylbenzoyl phenyl ethyl phosphonate; The anti-aging agent is dilauryl thiodipropionate; The spice is menthol propylene glycol carbonate .

[0030] A preparation method of environment-friendly high-strength UV glue, comprising the following steps:

[0031] 1) Weigh 45 parts of epoxy acrylate and 45 parts of modified urethane acrylate into the double planetary power mixing mixer, vacuumize to a vacuum degree of 0.12MPa, heat up to 220°C and dissol...

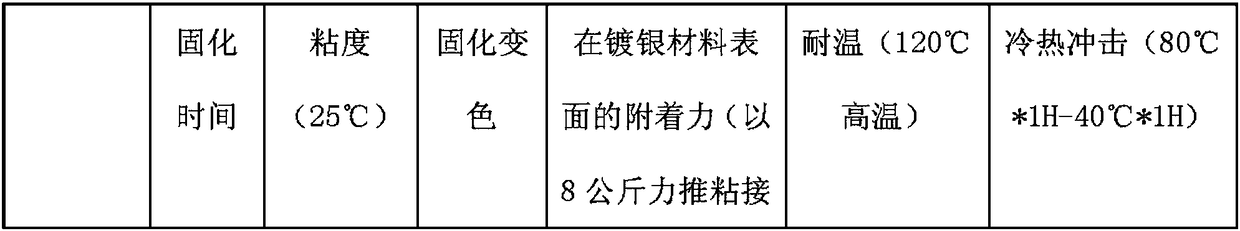

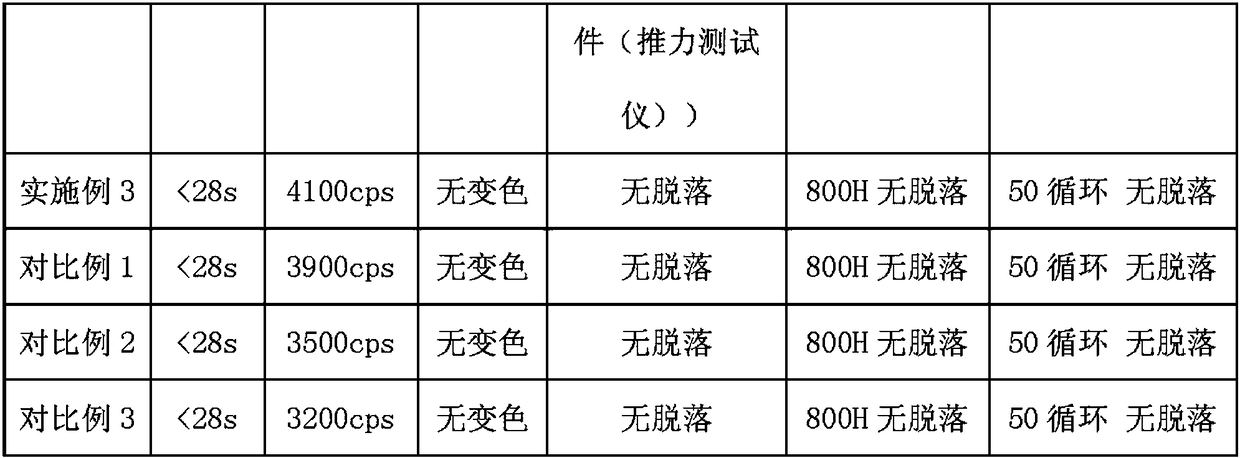

Embodiment 3

[0034] An environment-friendly high-strength UV glue, comprising the following raw materials in parts by weight: 38 parts of epoxy acrylate, 38 parts of modified polyurethane acrylate, 7 parts of honey, 9.5 parts of viscosity enhancer, 25 parts of photoinitiator, anti-aging 22 parts of agent, 8 parts of polyvinyl alcohol, 6 parts of dibutyl phthalate, 3.5 parts of silicon micropowder, 3.5 parts of sodium pyrophosphate, 3 parts of fragrance, 15 parts of xanthan gum; the viscosity enhancer is polyurethane; The photoinitiator is 2-hydroxyl-2-methyl-1-phenylacetone; the antiaging agent is a tertiary amine; and the fragrance is menthyl glutarate.

[0035] A preparation method of environment-friendly high-strength UV glue, comprising the following steps:

[0036] 1) Weigh 38 parts of epoxy acrylate and 38 parts of modified urethane acrylate into the dual planetary power mixing mixer, vacuumize until the vacuum degree is -0.08MPa, heat up to 200°C and dissolve completely, start stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com