Carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst for double-light reduction of co 2 Methods

A technology of zinc phthalocyanide and heterojunction is applied in the field of conversion and utilization of greenhouse gas CO2, which can solve the problems of difficult large-scale application, many organic acid products, and reduced reaction yield, so as to improve the overall conversion efficiency and improve separation. Efficiency, the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

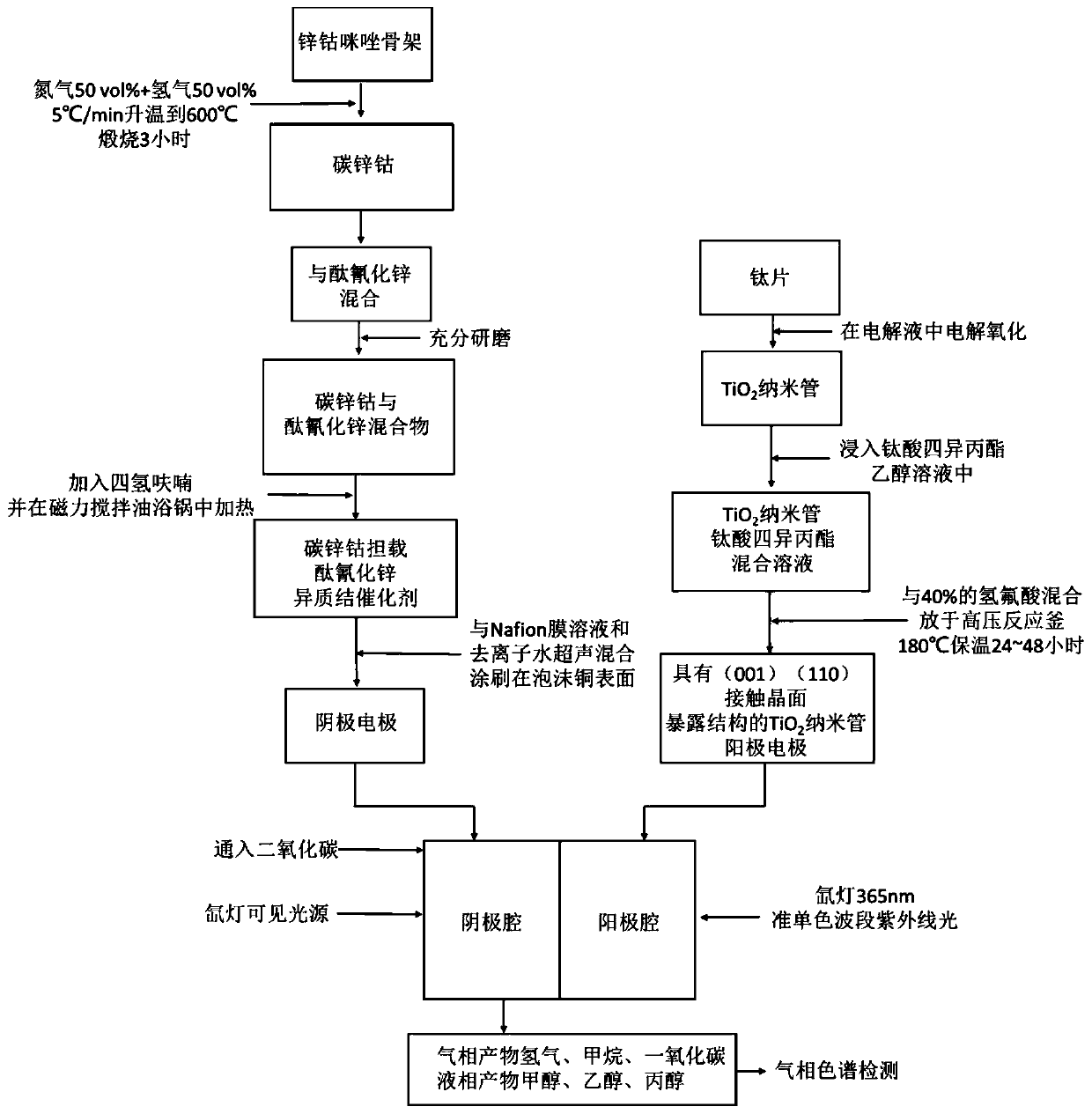

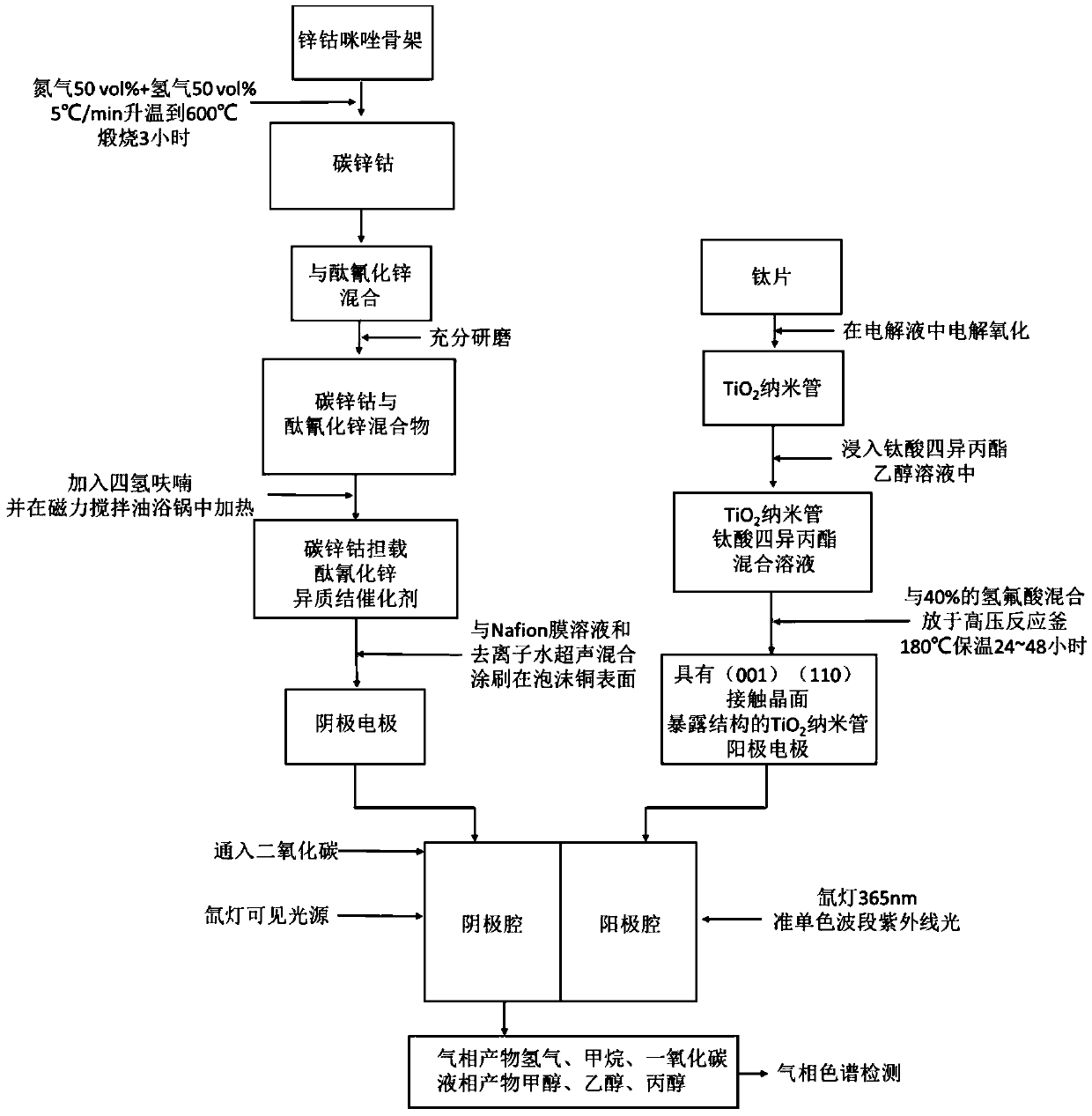

[0037] Take 1g of zinc-cobalt imidazole framework (Zn / Co ZIF) (average diameter 500nm) and put it into a tube furnace, and raise the temperature to 600°C at 5°C / min in a mixed gas of nitrogen and hydrogen (nitrogen 50vol%+hydrogen 50vol%) , and heated at constant temperature for 3 hours to obtain a calcined product. The calcined product was mixed with 0.1g of zinc phthalocyanide (purchased from Sinopharm Group), fully ground and added to 50ml of tetrahydrofuran liquid (purchased from Sinopharm Group), and heated at 80°C in a magnetically stirred oil bath to evaporate all the liquid. The solids obtained after evaporation were mixed, then placed in a muffle furnace to raise the temperature to 300°C at 5°C / min, and calcined at a constant temperature for 2 hours to prepare a carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst. Take 10 mg of this catalyst, 100 μL of deionized water, and 200 μL of Nafion solution (purchased from DuPont) with a mass concentration...

Embodiment 2

[0039] Take 10g of zinc-cobalt imidazole framework (Zn / Co ZIF) (average diameter 500nm) and put it into a tube furnace, and raise the temperature to 600°C at 5°C / min in a mixed gas of nitrogen and hydrogen (nitrogen 50vol%+hydrogen 50vol%) , and heated at constant temperature for 3 hours to obtain a calcined product. Mix the calcined product with 1g of zinc phthalocyanide (purchased from Sinopharm Group), grind it thoroughly and add it to 500ml of tetrahydrofuran liquid (purchased from Sinopharm Group), heat in a magnetically stirred oil bath at 80°C to evaporate all the liquid, evaporate The obtained solids were mixed, then placed in a muffle furnace to raise the temperature to 300° C. at 5° C. / min, and calcined at a constant temperature for 2 hours to prepare a porous carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst. Take 50 mg of this catalyst, 500 μL of deionized water, and 1000 μL of Nafion solution (purchased from DuPont) with a mass concentration...

Embodiment 3

[0041] Take 100g of zinc-cobalt imidazole framework (Zn / Co ZIF) (average diameter 500nm) and put it into a tube furnace, and raise the temperature to 600°C at 5°C / min in a mixed gas of nitrogen and hydrogen (nitrogen 50vol%+hydrogen 50vol%) , and heated at constant temperature for 3 hours to obtain a calcined product. The calcined product was mixed with 10g of zinc phthalocyanide (purchased from Sinopharm Group), fully ground and added to 5000ml of tetrahydrofuran liquid (purchased from Sinopharm Group), and heated at 80°C in a magnetically stirred oil bath to evaporate all the liquid. The obtained solids were mixed, then placed in a muffle furnace to raise the temperature to 300° C. at 5° C. / min, and calcined at a constant temperature for 2 hours to prepare a porous carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst. Take 100 mg of this catalyst, 1000 μL of deionized water, and 2000 μL of Nafion solution (purchased from DuPont) with a mass concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com