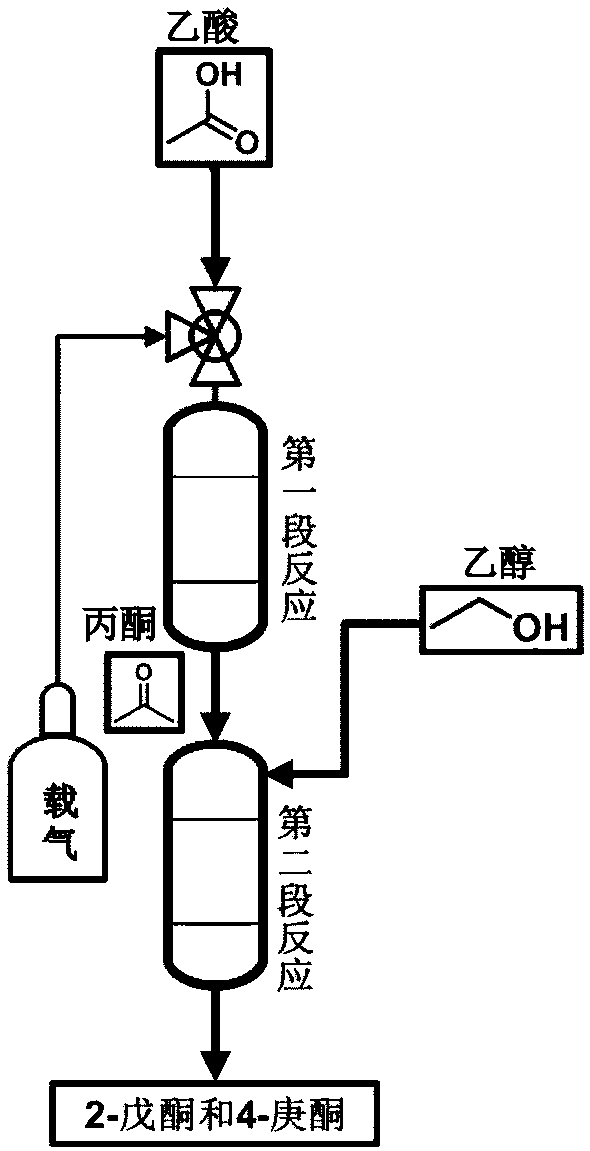

Method for preparing ketone compounds from acetic acid and ethanol by using two-stage method

A technology of ketone compounds and acetic acid, which is applied in the field of preparation of ketone compounds, can solve the problems of unsustainability and scale limitation, and achieve the effects of good activity and stability, low price and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Catalyst preparation

[0012] CeO 2 The preparation adopts the precipitation method. Weigh 25g of cerium nitrate hexahydrate and dissolve it in 2.5L of water, add ammonia water with a mass concentration of 27% to adjust the pH=11, stir for 4h, filter, dry, and roast at 500°C for 4h to obtain 10g of CeO 2 . CeO 2 -SnO 2 Composite metal oxide adopts co-precipitation method, weighs 25g of cerium nitrate hexahydrate and dissolves it in 2.5L of water, and adds a certain amount of tin chloride, CeO 2 :SnO 2 =5:1 (mass ratio), add ammonia water with a mass concentration of 27% to adjust the pH=11, precipitate appears, continue to stir for 4 hours, centrifuge the obtained precipitate, dry, and roast at 500°C for 4 hours to obtain CeO 2 -SnO 2 Composite metal oxide catalyst.

[0013] Preparation of ketones

[0014] Form and sieve the above two catalysts with 14-25 mesh respectively and fill them into the reaction tube. The first stage filled catalyst is CeO 2 , the he...

Embodiment 2

[0016] Catalyst preparation

[0017] CeO 2 The preparation adopts the precipitation method. Weigh 25g of cerium nitrate hexahydrate and dissolve it in 2.5L of water, add ammonia water with a mass concentration of 27% to adjust the pH=11, stir for 4h, filter, dry, and roast at 500°C for 4h to obtain 10g of CeO 2 . CeO 2 -SnO 2 Composite metal oxide adopts co-precipitation method, weighs 25g of cerium nitrate hexahydrate and dissolves it in 2.5L of water, and adds a certain amount of tin chloride, CeO 2 :SnO 2 =5:1 (mass ratio), add ammonia water to adjust pH=11, precipitate appears, continue to stir for 4 hours, centrifuge the resulting precipitate, dry, and roast at 500°C for 4 hours to obtain CeO 2 -SnO 2 Composite metal oxide catalyst.

[0018] Preparation of ketones

[0019] Form and sieve the above two catalysts with 14-25 mesh respectively and fill them into the reaction tube. The first stage filled catalyst is CeO 2 , the height of the packed bed is 6cm, the r...

Embodiment 3

[0021] Catalyst preparation

[0022] CeO 2 The preparation adopts the precipitation method. Weigh 25g of cerium nitrate hexahydrate and dissolve it in 2.5L of water, add ammonia water with a mass concentration of 27% to adjust the pH=11, stir for 4h, filter, dry, and roast at 500°C for 4h to obtain 10g of CeO 2 . CeO 2 -SnO 2 Composite metal oxide adopts co-precipitation method, weighs 25g of cerium nitrate hexahydrate and dissolves it in 2.5L of water, and adds a certain amount of tin chloride, CeO 2 :SnO 2 =5:1 (mass ratio), add ammonia water to adjust pH=11, precipitate appears, continue to stir for 4 hours, centrifuge the resulting precipitate, dry, and roast at 500°C for 4 hours to obtain CeO 2 -SnO 2 Composite metal oxide catalyst.

[0023] Preparation of ketones

[0024] Form and sieve the above two catalysts with 14-25 mesh respectively and fill them into the reaction tube. The first stage filled catalyst is CeO 2 , the height of the packed bed is 6cm, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com