Anticorrosive photo-responsive and self-healing shape-memory polyurethane coating and preparation method thereof

An anti-corrosion coating and self-repairing technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., to achieve flexible application, prolong service life, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

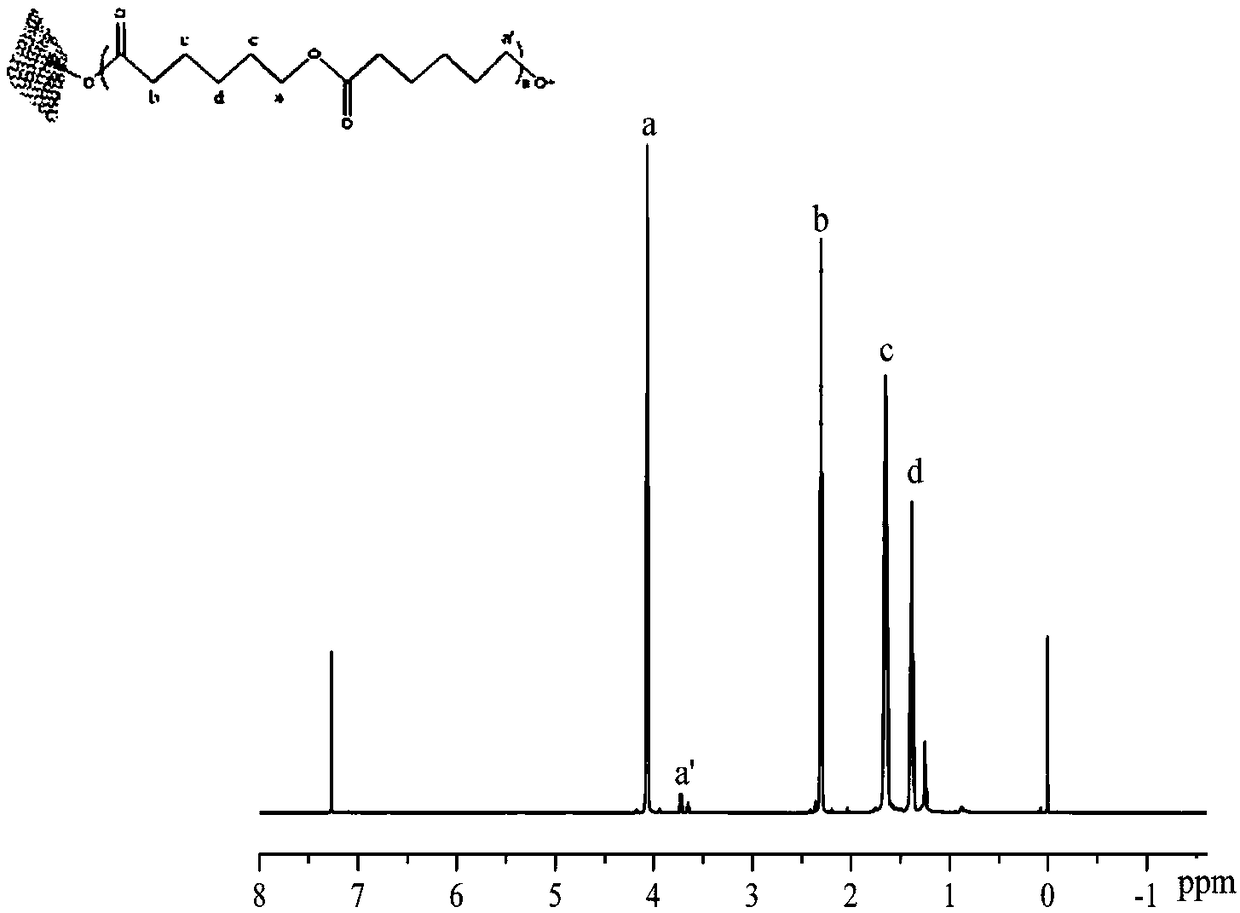

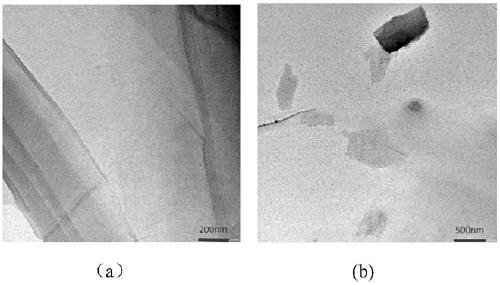

[0045] Weigh 0.025g of graphene oxide (GO) into a flask containing 24.975g of polycaprolactone, 400W ultrasonic dispersion for 60mins, to obtain a uniformly dispersed material. Under the protection of nitrogen, heat and stir in an oil bath at 130°C, add 20 microliters of stannous octoate dropwise, and react for 24 hours to obtain GO-PCL-0.1% grafted polymer.

[0046] Weigh 2.000g of GO-PCL-0.1% grafted polymer, add 20mL of N,N dimethylformamide (DMF) and 0.400g of 4,4`-diphenylmethane diisocyanate (MDI), the mass concentration of 0.240g is 2 % dibutyltin dilaurate (DBTDL) catalyst in DMF, stirred at 80° C. for 5 h under nitrogen protection to obtain a solution.

[0047] The resulting solution was coated on the metal surface and cured at 80°C for 12 hours to obtain a shape memory self-healing coating containing GO-SMP-0.1%.

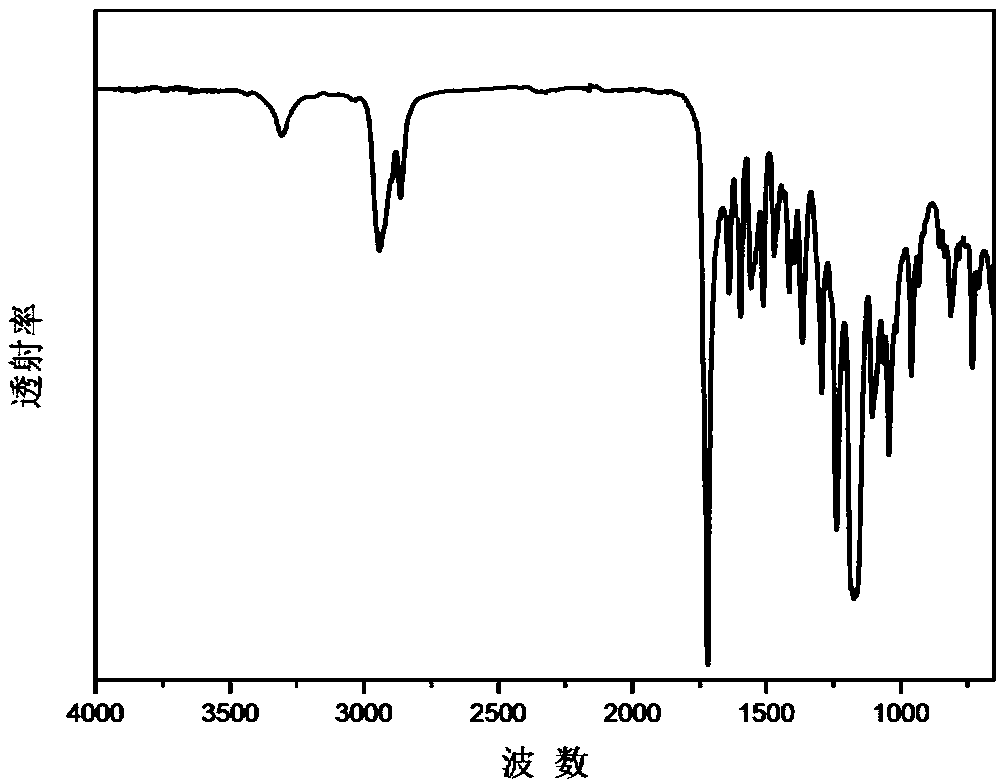

[0048] see figure 1 , the infrared spectrogram of the shape-memory self-healing polyurethane coating provided in this example, 3327cm can be seen in the...

Embodiment 2

[0055] Preparation of GO-PCL-0.1% catalyst with 0.5% self-healing coating metal.

[0056] 1) Synthesize the polymer grafted GO-PCL-0.1% according to Example 1.

[0057] 2) Weigh 2.000g of GO-PCL-0.1% grafted polymer, add 20mL of N,N dimethylformamide (DMF) and 0.400g of 4,4`-diphenylmethane diisocyanate (MDI), 1.200g mass concentration It is a DMF solution of 2% dibutyltin dilaurate (DBTDL) catalyst, stirred at 80° C. for 5 h under the protection of nitrogen to obtain a solution.

[0058] The resulting solution was coated on the metal surface and cured at 80°C for 12 hours to obtain a shape memory self-healing coating containing GO-SMP-0.5%.

[0059] Polarizing microscope and scanning electron microscope were taken before and after the repair of the polyurethane coating according to Example 1, which proved that the coating can be effectively self-repaired.

Embodiment 3

[0061] Preparation of GO-PCL-0.1% catalyst with 1% self-healing coating metal.

[0062] 1) Synthesize the polymer grafted GO-PCL-0.1% according to Example 1.

[0063] 2) Weigh 2.000gGO-PCL-0.1% grafted polymer, add 20mL N,N dimethylformamide (DMF) and 0.400g4,4'-diphenylmethane diisocyanate (MDI), 2.400g mass concentration It is a DMF solution of 2% dibutyltin dilaurate (DBTDL) catalyst, stirred at 80° C. for 5 h under the protection of nitrogen to obtain a solution.

[0064] The resulting solution was coated on the metal surface and cured at 80°C for 12 hours to obtain a shape memory self-healing coating containing GO-SMP-1%.

[0065] Polarizing microscope and scanning electron microscope were taken before and after the repair of the polyurethane coating according to Example 1, which proved that the coating can be effectively self-repaired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com