Preparation method of mung bean protein peptide-zinc chelate

A technology of mung bean protein and zinc chelate, applied in the field of food processing, can solve problems such as low absorption rate, and achieve the effects of promoting absorption, improving preparation efficiency, and improving absorption utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example illustrates the preparation process of mung bean protein peptide-zinc chelate.

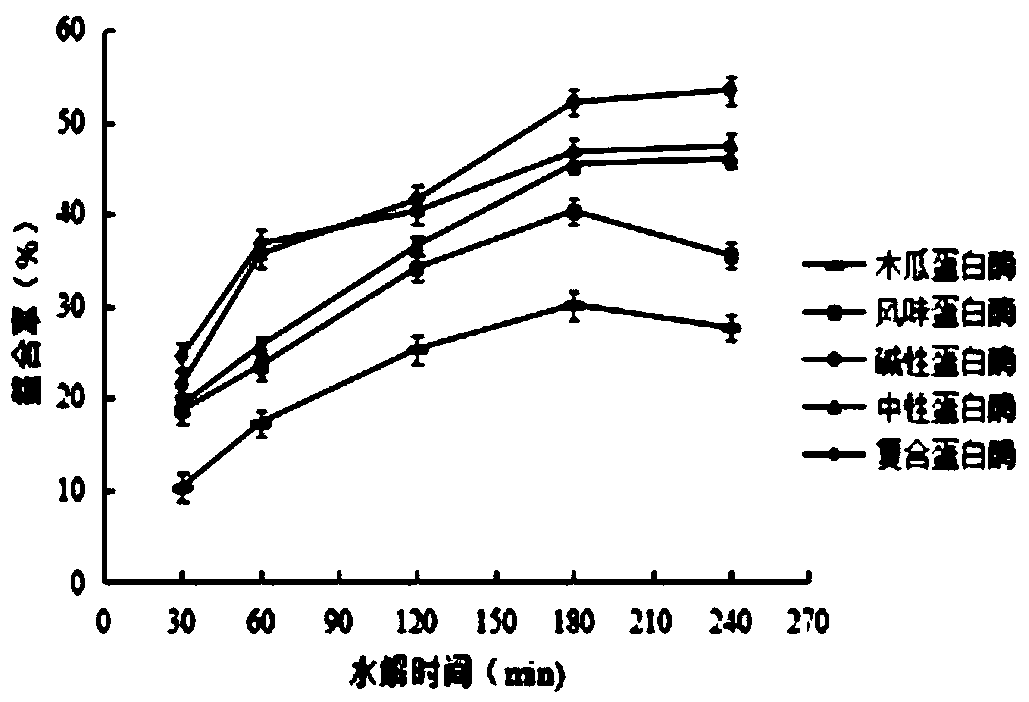

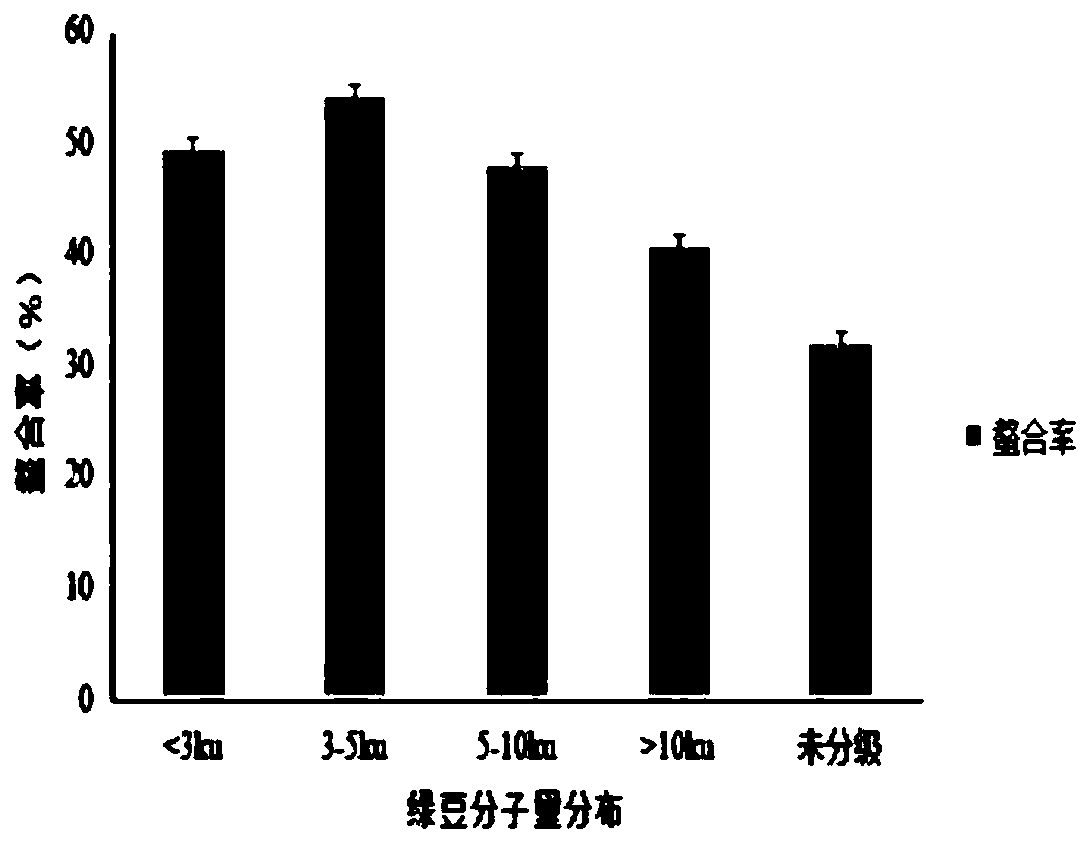

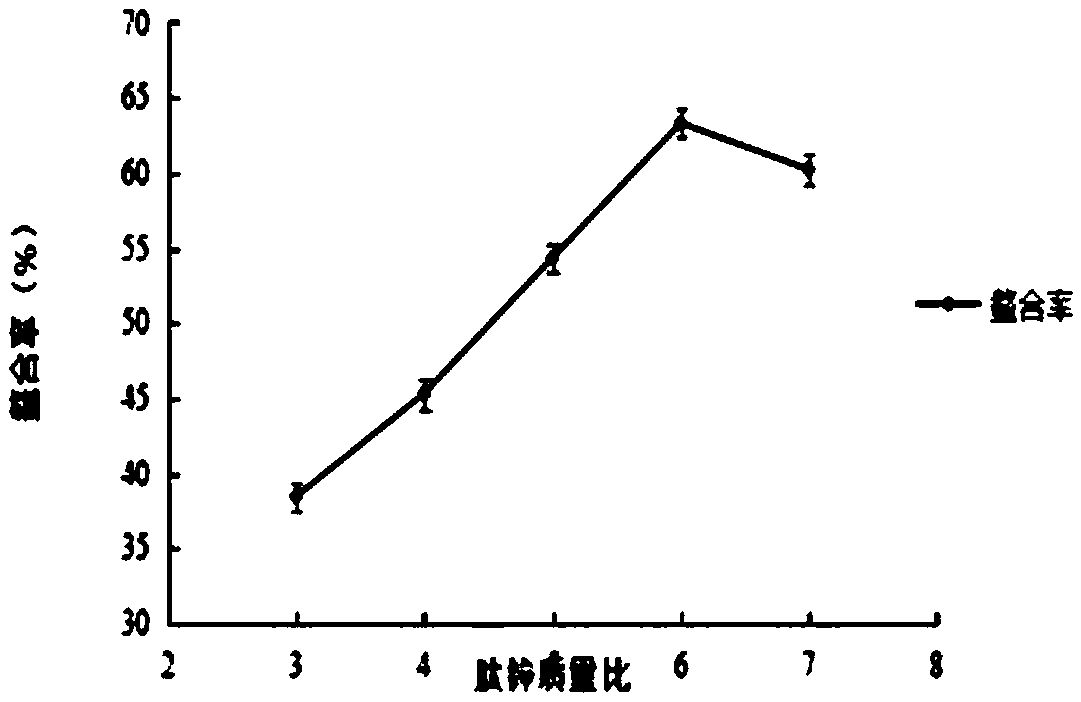

[0027] Dissolve 50g of mung bean protein in 1.25L of deionized water, and pretreat it in a 90°C water bath for 15 minutes. After the temperature drops to 55°C, adjust the pH to 9 with 0.5mol / L NaOH, add 4ml of alkaline protease, and use 0.5mol / L NaOH kept the pH at 9, and after hydrolysis for 4 hours, the enzyme was killed in a boiling water bath; the hydrolyzed solution was cooled to room temperature, adjusted to pH 7 with 1mol / L_HCL, centrifuged at 5000r / min for 15min, and the supernatant was taken; The supernatant was ultrafiltered under a pressure of 0.25MPa, followed by ultrafiltration through ultrafiltration membranes with a molecular mass of 5 and 3ku to obtain a mung bean protein peptide filtrate with a molecular mass of 3-5ku, and the fractionated peptides were filtered through 6.08g mung bean protein peptide was dissolved in 121.6ml deionized water to make a peptide s...

Embodiment 2

[0029] This example illustrates the preparation process of mung bean protein peptide-zinc chelate.

[0030] Dissolve 50g of mung bean protein in 1.25L of deionized water, and pretreat it in a 90°C water bath for 15 minutes. After the temperature drops to 55°C, adjust the pH to 9 with 0.5mol / L NaOH, add 4ml of alkaline protease, and use 0.5mol / L NaOH to keep the pH at 9, and after hydrolysis for 4 hours, boil the water bath to kill the enzyme; cool the hydrolyzate to room temperature, adjust the pH value to 7 with 1mol / L HCL, centrifuge at 5000r / min for 15min, and take the supernatant; The supernatant was ultrafiltered under the pressure of 0.25MPa, followed by ultrafiltration with ultrafiltration membranes with a molecular mass of 5 and 3ku to obtain mung bean protein peptide filtrate with a molecular mass of 3-5ku, and the fractionated peptides were permeated After liquid freeze-drying, it is ready for use; dissolve 3g mung bean protein peptide in 60ml deionized water to make...

Embodiment 3

[0032]This example illustrates the preparation process of mung bean protein peptide-zinc chelate.

[0033] Dissolve 50g of mung bean protein in 1.25L of deionized water, and pretreat it in a 90°C water bath for 15 minutes. After the temperature drops to 55°C, adjust the pH to 9 with 0.5mol / L NaOH, add 4ml of alkaline protease, and use 0.5mol / L NaOH to keep the pH at 9, and after hydrolysis for 4 hours, boil the water bath to kill the enzyme; cool the hydrolyzate to room temperature, adjust the pH value to 7 with 1mol / L HCL, centrifuge at 5000r / min for 15min, and take the supernatant; The supernatant was ultrafiltered under the pressure of 0.25MPa, followed by ultrafiltration with ultrafiltration membranes with a molecular mass of 5 and 3ku to obtain mung bean protein peptide filtrate with a molecular mass of 3-5ku, and the fractionated peptides were permeated After liquid freeze-drying for later use; dissolve 7g mung bean protein peptide in 140ml deionized water to prepare a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com