Tin-doped molybdenum oxide thin film, wide-spectrum photodetector array based on tin-doped molybdenum oxide thin film and preparation method thereof

A photodetector, molybdenum oxide technology, used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of difficulty in preparing doped molybdenum oxide thin films, complicated procedures, etc., and achieve good humidity and thermal stability. Large layer area and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can understand the features and advantages of the present invention, so as to define the protection scope of the present invention more clearly.

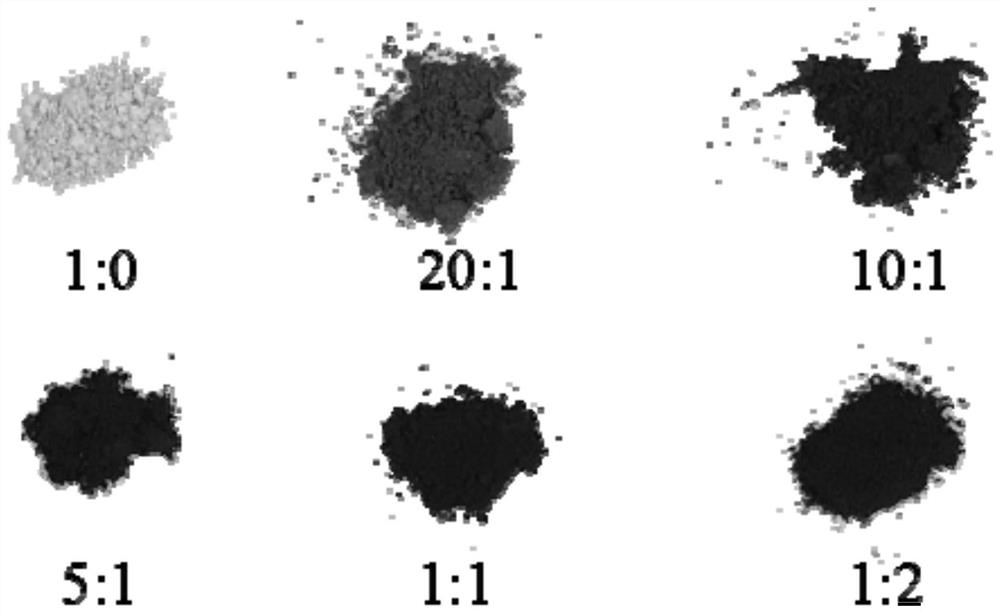

[0030] The tin-doped molybdenum oxide thin film of the invention is formed by grinding molybdenum oxide powder and tin protochloride powder and vapor-depositing. In the tin-doped molybdenum oxide thin film, the tin / molybdenum molar ratio is 0.038-1.52.

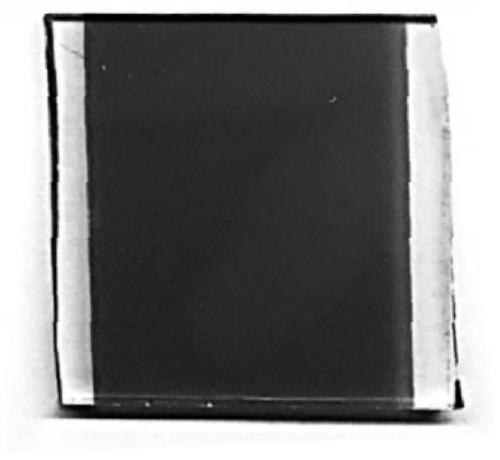

[0031] A wide-spectrum photodetector array prepared by using the tin-doped molybdenum oxide film, which includes a substrate, a tin-doped molybdenum oxide film on the substrate, and an electrode array on the tin-doped molybdenum oxide film;

[0032] The substrate can be an insulating substrate or a conductive substrate, and the insulating substrate can be quartz glass, SiO 2 or Al 2 o 3 , sapphire or PET and other in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

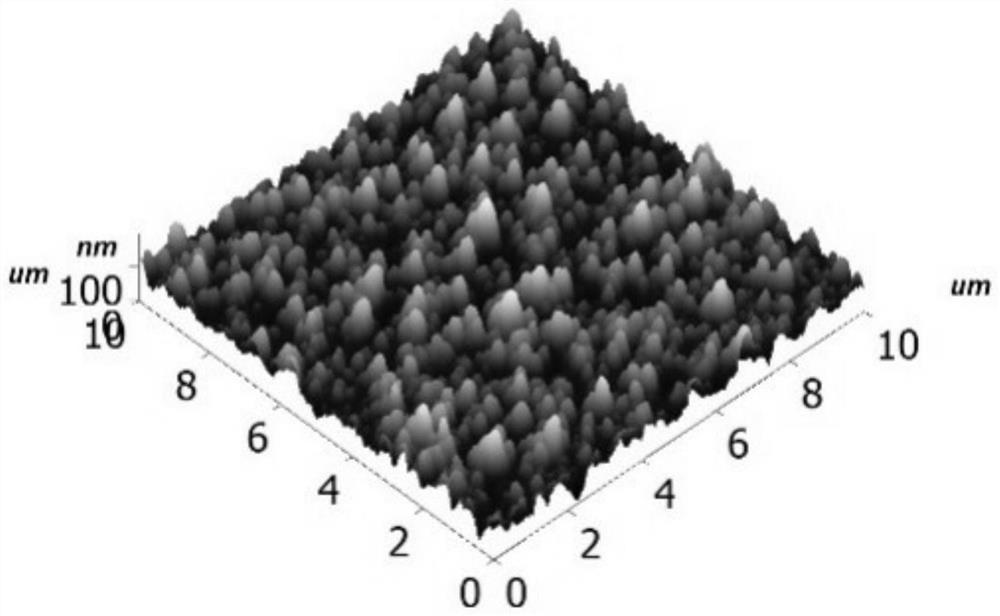

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com