Hyperstable monodisperse fluorescent magnetic diagnosis and treatment nanoprobe and preparation method and application thereof

A nano-probe and magnetic nano-technology, which is applied in the field of ultra-stable monodisperse fluorescent magnetic diagnosis and treatment nano-probes and its preparation, can solve the problems of retention time and aggregation amount of tumor sites that are difficult to achieve as desired, and achieve magnetic properties Excellent, high targeting efficiency, simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

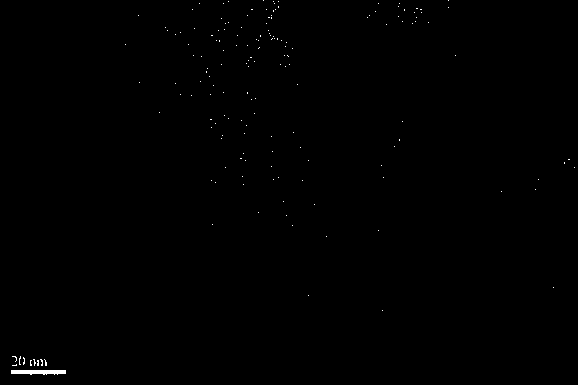

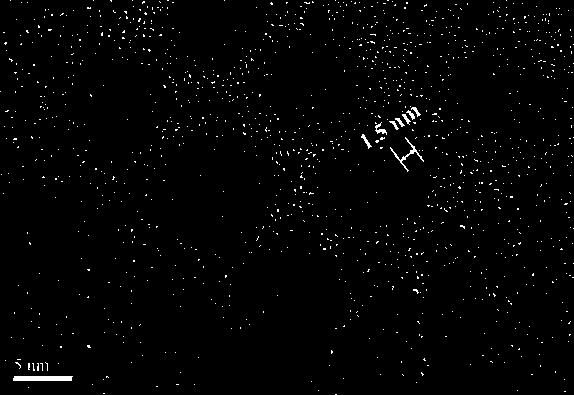

[0034] (1) Preparation of magnetic particles (carboxylation): Weigh ferrous sulfate and ferric citrate with a molar ratio of 1:1, dissolve them in deionized water, stir at a speed of 600 rpm to make them well mixed; then add a certain amount of amount of ascorbic acid to make it compatible with Fe 3+ The molar ratio of ions was 1:3, and 0.5 M sodium hydroxide solution was used to adjust the pH value of the reaction solution to 9. After stirring for 120 min, the mixed solution was transferred to a hydrothermal reaction kettle and kept at 150 °C for 4 h; Dialyzed for 2 days to obtain MNPs-COOH suspension solution, which was then placed in a 4°C refrigerator for long-term storage;

[0035] (2) PEGylation of magnetic nanoparticles: Take 1 mL of the MNPs-COOH suspension solution, transfer it to a 10K ultrafiltration tube and centrifuge. The parameters of the refrigerated centrifuge are set to: 4 °C, 12000 rpm, 5 min; Make up to 7.2 of borate buffer to the original volume, the carb...

Embodiment approach 2

[0040] (1) Preparation of magnetic particles (carboxylation): Weigh ferrous sulfate and ferric citrate with a molar ratio of 1:2, dissolve them in deionized water, stir at a speed of 600 rpm to make them well mixed; then add a certain amount of amount of ascorbic acid to make it compatible with Fe 3+ The molar ratio of ions was 1:2, and 0.5 M sodium hydroxide solution was used to adjust the pH value of the reaction solution to 10. After stirring for 120 min, the mixed solution was transferred to a hydrothermal reaction kettle and kept at 150 °C for 4 h; Dialyzed for 2 days to obtain MNPs-COOH suspension solution, which was then placed in a 4°C refrigerator for long-term storage;

[0041] (2) PEGylation of magnetic nanoparticles: Take 1 mL of the MNPs-COOH suspension solution, transfer it to a 10K ultrafiltration tube and centrifuge. The parameters of the refrigerated centrifuge are set to: 4 °C, 12000 rpm, 5 min; Make up to 7.2 of borate buffer to the original volume, the car...

Embodiment approach 3

[0045] (1) Preparation of magnetic particles (carboxylation): Weigh ferrous sulfate and ferric citrate with a molar ratio of 1:1, dissolve them in deionized water, stir at a speed of 600 rpm to make them well mixed; then add a certain amount of amount of ascorbic acid to make it compatible with Fe 3+ The molar ratio of ions was 1:3, and the pH value of the reaction solution was adjusted to 12 with 0.5 M sodium hydroxide solution. After stirring for 120 min, the mixed solution was transferred to a hydrothermal reaction kettle, and the temperature was kept at 150 °C for 4 h; Dialyzed for 2 days to obtain MNPs-COOH suspension solution, which was then placed in a 4°C refrigerator for long-term storage;

[0046] (2) PEGylation of magnetic nanoparticles: Take 1 mL of the MNPs-COOH suspension solution, transfer it to a 10K ultrafiltration tube and centrifuge. The parameters of the refrigerated centrifuge are set to: 4 °C, 12000 rpm, 5 min; Make up to 7.2 of borate buffer to the orig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com