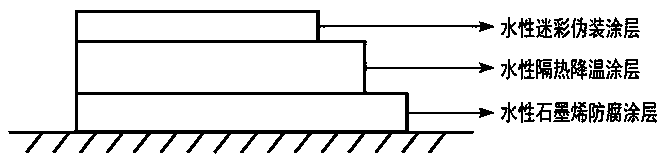

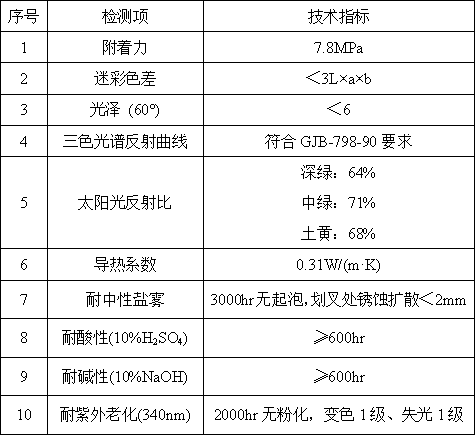

Waterborne anti-corrosion heat insulation camouflage painting composite coating

A composite coating and anti-corrosion technology, applied in anti-corrosion coatings, camouflage coatings, coatings, etc., can solve the potential hazards of the coating environment and construction personnel, can not adapt to high temperature, high humidity, high salt spray, non-compliant Issues such as environmental protection policies to achieve the effect of increasing the effectiveness of camouflage, resisting multi-method detection, and reducing the risk of discovery and identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: preparation of khaki camouflage topcoat

[0030] (1) A component

[0031] In parts by mass, it contains the following raw materials: 37 parts of hydroxyacrylic acid emulsion, 3 parts of environmentally friendly solvent, TiO 2 6 parts, iron yellow 15.8 parts, iron red 3.1 parts, brown black 2.3 parts, heat reflective powder (TiO 2 Coated nano hollow microspheres) 8.3 parts, aluminum silver paste (aluminum powder particle size 800 mesh, content 40 wt%) 1.6 parts, silica matting agent 1.8 parts, defoaming agent 0.4 parts, wetting agent 0.2 parts, 0.3 parts of leveling agent, 2.6 parts of dispersant, 0.3 parts of anti-settling agent, 17.3 parts of deionized water.

[0032] (2) B component

[0033] Component B is a 100 wt% solid polyisocyanate prepolymer mixture.

[0034] When using, mix components A and B evenly at a mass ratio of 6:1, filter through a 100-mesh sieve, and then apply.

Embodiment 2

[0035] Embodiment 2: preparation of medium green camouflage topcoat

[0036] (1) A component

[0037] In parts by mass, it contains the following raw materials: 36 parts of hydroxyacrylic acid emulsion, 3.2 parts of environmentally friendly solvent, TiO 2 4 parts, 18.7 parts of chrome green, 4.1 parts of medium chrome yellow, 1.2 parts of ITO powder, heat reflective powder (Y 2 o 3 doped nano TiO 2 ) 6.4 parts, aluminum silver paste (aluminum powder particle size 500 mesh, content 30 wt%) 1.7 parts, bentonite matting agent 1.5 parts, defoamer 0.3 parts, wetting agent 0.3 parts, leveling agent 0.3 parts, anti-settling agent 0.5 parts, 2.4 parts of dispersant, 19.4 parts of deionized water.

[0038] (2) B component

[0039] Component B is a 100 wt% solid polyisocyanate prepolymer mixture.

[0040] When using, mix components A and B evenly at a mass ratio of 6:1, filter through a 100-mesh sieve, and then apply.

Embodiment 3

[0041] Embodiment 3: dark green camouflage topcoat preparation

[0042] (1) A component

[0043] In parts by mass, it contains the following raw materials: 40 parts of hydroxyacrylic acid emulsion, 3.2 parts of environmentally friendly solvent, TiO 2 3.8 parts, 16.7 parts of cobalt green, 1.1 parts of medium chrome yellow, 2.8 parts of brown and black, heat reflective powder (TiO 2 Coated nano hollow microspheres) 8 parts, polyethylene wax matting agent 1.4 parts, defoaming agent 0.4 parts, wetting agent 0.3 parts, leveling agent 0.3 parts, anti-settling agent 0.7 parts, dispersant 2.4 parts, deionization 18.9 parts of water.

[0044] (2) B component

[0045] Component B is a 100 wt% solid polyisocyanate prepolymer mixture.

[0046] When using, mix components A and B evenly at a mass ratio of 6:1, filter through a 100-mesh sieve, and then apply.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com