A method for analyzing and identifying fatty alcohol polyoxyethylene ether surfactants

A technology of alcohol polyoxyethylene ether and surfactant, which is applied in the field of analysis and testing, and can solve the problems of shortening the pretreatment time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

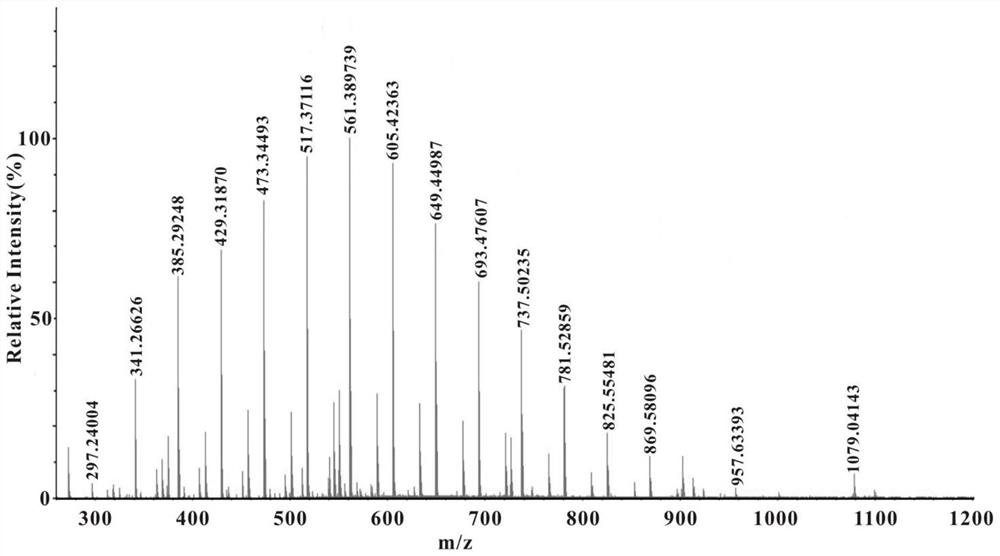

[0045] In this example, the rapid analysis and identification of the relative molecular mass distribution, element composition of each component, alkyl chain length and ethylene oxide polymerization degree of AEO-3 includes the following steps:

[0046] (1) Solution preparation

[0047] Preparation of 2,5-DHB solution: Accurately weigh 0.02000g 2,5-DHB and dissolve it in acetonitrile aqueous solution 7:3 (v / v) to prepare 20mg / mL 2,5-DHB solution;

[0048] Preparation of 2,5-DHB+1mM NaCl matrix solution: Accurately weigh 0.05850g sodium chloride in a 100mL volumetric flask, add water to the mark, shake well, pipette 10μL into 990μL of the above 2,5-DHB matrix to prepare into 2,5-DHB+1mM NaCl matrix solution.

[0049] Sample preparation: Dissolve 1 μL of AEO-3 sample in 1 mL of ultrapure water, and sonicate for 5 minutes to obtain a sample solution. The above matrix solution was mixed with the sample solution at a ratio of 9:1 (v / v), and 1 μL of the mixed solution was dropped ...

Embodiment 2

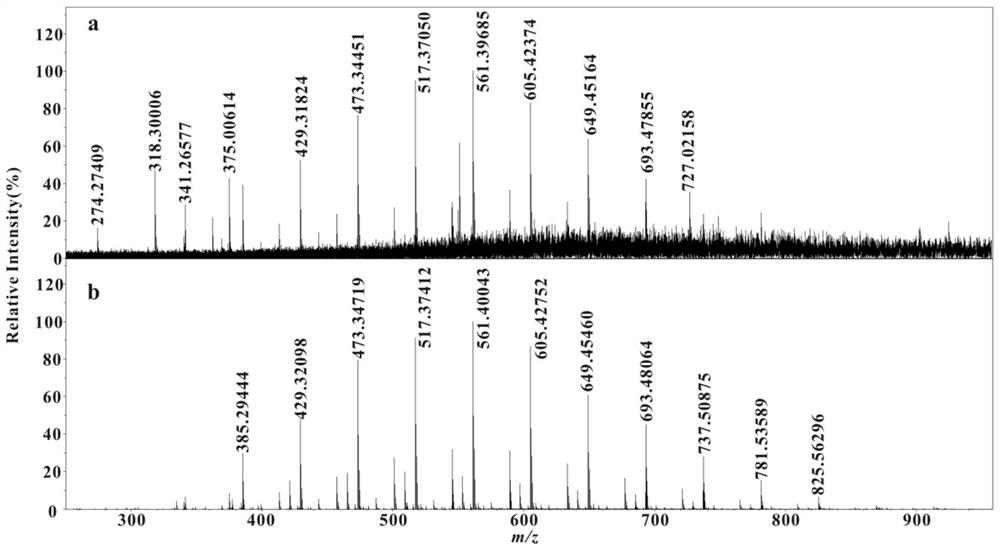

[0063] Same as Example 1, the difference is:

[0064] (1) Solution preparation

[0065] The molar concentration of sodium chloride in the sodium chloride solution is 0.5mmol / L.

[0066] (2) Experimental conditions

[0067] MALDI conditions: In positive ion mode, the laser energy is 10%, the medium mode spot, the laser frequency is 100Hz, the number of irradiation is 200Shots, and the action path is Random.

[0068] FT-ICR MS conditions: set the sampling size to 512K, the number of accumulations to 64, the harmony trap accumulation time to 0.050s, and the mass-to-charge ratio range to 100-1500Da.

Embodiment 3

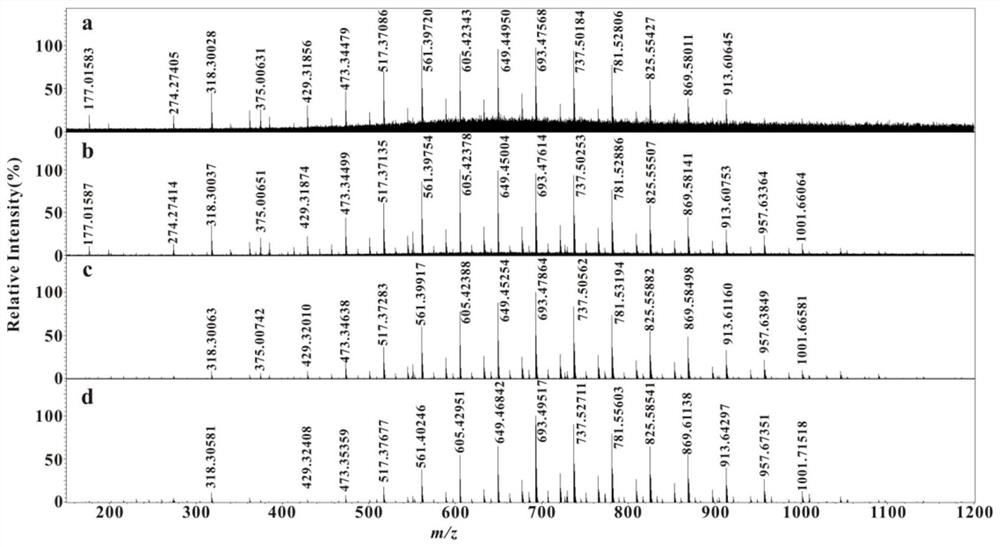

[0070] Same as Example 1, the difference is:

[0071] (1) Solution preparation

[0072] Sodium chloride solution is supersaturated sodium chloride solution. The molar concentration of supersaturated sodium chloride solution is 5.43mol / L.

[0073] At room temperature, the solubility of sodium chloride is about 36g / 100g, the mass fraction of saturated sodium chloride solution is 36 / 136, and the density is 1.20g / mL, then the molar concentration of supersaturated sodium chloride solution c=1000*1.20*36 / 136 / 58.5=5.43 mol / L.

[0074] (2) Experimental conditions

[0075] MALDI conditions: In positive ion mode, the laser energy is 50%, the light spot in Medium mode, the laser frequency is 200Hz, the number of irradiation is 1Shots, and the action path is Random.

[0076] FT-ICR MS conditions: set the sampling size to 4M, the number of accumulation times to 1, the harmony trap accumulation time to 0.001s, and the mass-to-charge ratio range to 100-1500Da.

[0077] The result that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com