Continuous combustion production equipment for synthesizing tonnage fullerene and synthesis method thereof

A kind of production equipment and fullerene technology, applied in the field of fullerene, can solve the problems of unbalanced air pressure, low output, easy glass bursting, etc., and achieve the effect of stable synthesis, safe synthesis process and strong anti-fluctuation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

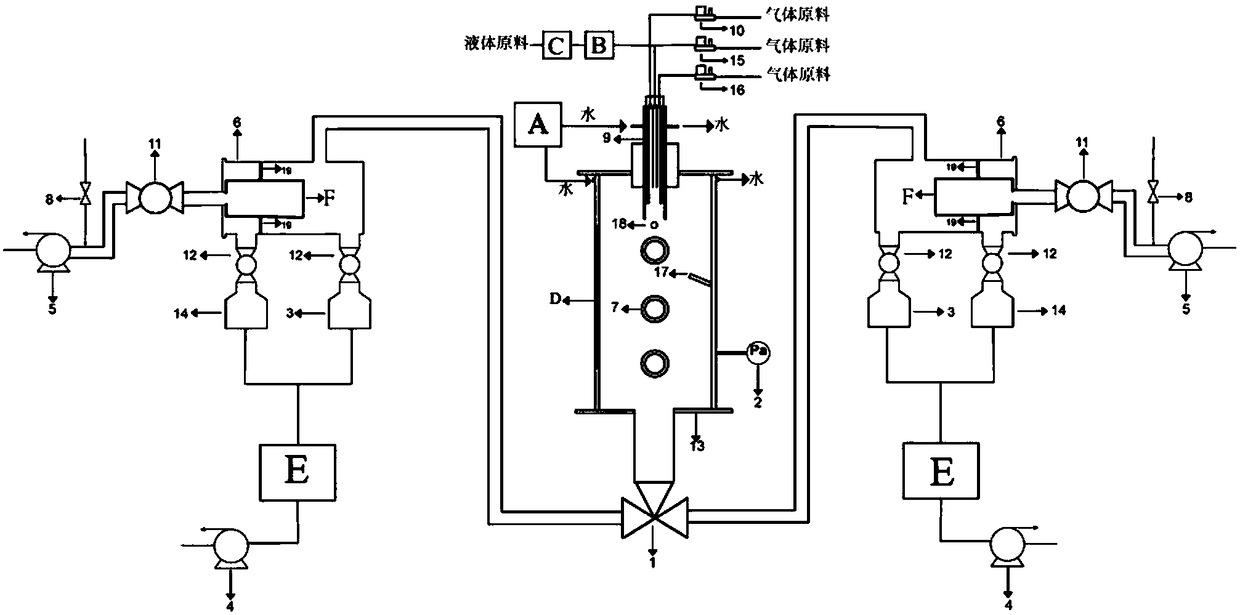

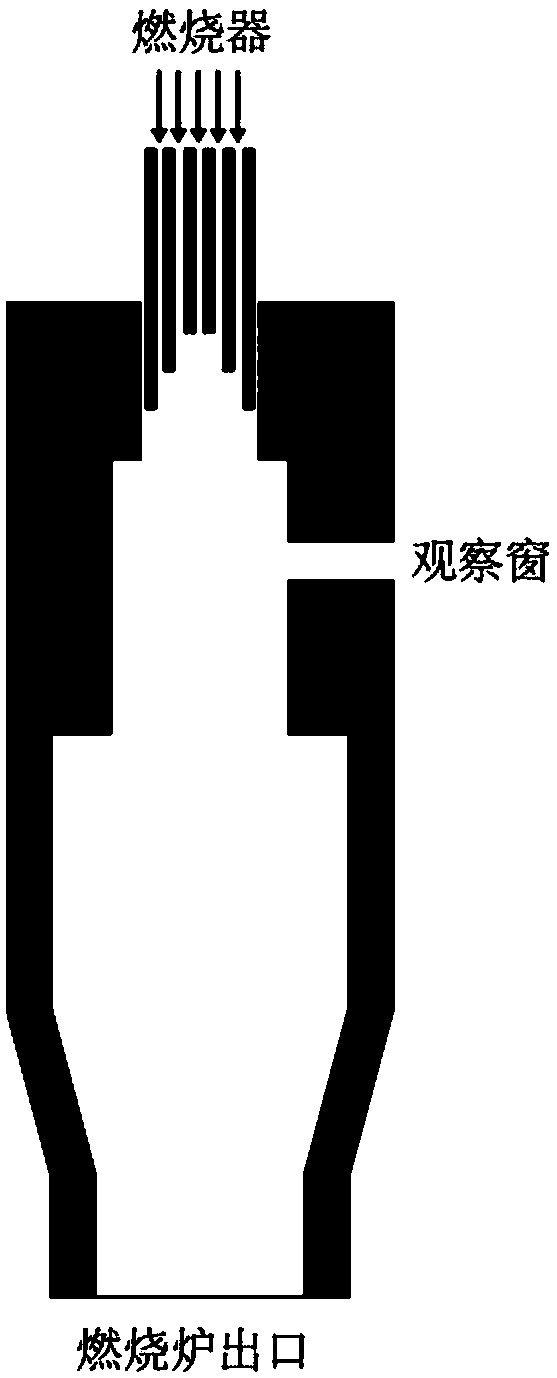

[0050] Embodiment 1, a kind of equipment that adopts combustion method to synthesize fullerene, such as figure 1 As shown, including gas supply and flow control system, liquid supply and flow control system, vaporization and preheating system, vacuum control system, ignition system, burner, combustion furnace body, atomizing nozzle, vacuum measurement and display device, product cleaning system, filter tank, circulating water cooling system and product collection tank.

[0051] The flow rate of the gas raw material is controlled by the first flow meter 10, the second flow meter 15, and the third flow meter 16; the flow rate of the liquid raw material is controlled by the constant flow pump B, and is heated and vaporized by the heater C whose set temperature is much higher than its boiling point. The gas raw material and the liquid raw material enter the burner 9 through the pipeline (the pipeline is wrapped around a heating belt to preheat the raw material) and enter the burne...

Embodiment 2

[0052] Embodiment 2, a kind of method of a large amount, continuous synthesis of fullerenes, adopt the equipment of embodiment 1, take technical grade pure oxygen as oxidant, take acetylene as gaseous fuel, take benzene as liquid raw material, carry out following steps successively:

[0053] 1), open the acetylene supply pipeline, adjust the flow rate to 35SLM through the second mass flow meter 15, place the metal electrode tip of the igniter near the acetylene gas outlet of the burner, turn on the igniter, and the electric spark ignites the acetylene to generate a flame;

[0054] 2) Start the vacuum pump group, open the first valve 1 and the second valve 11, open the oxygen gas supply pipeline at the same time, adjust the flow rates to 15SLM and 35SLM respectively through the first mass flow meter 10 and the third mass flow meter 16, and start the circulating water cooling system;

[0055] 3) Open the benzene supply pipeline, adjust the flow rate to 30mL / min through the const...

Embodiment 3

[0069] Embodiment 3, make the following changes with respect to embodiment 2:

[0070] In step 3), the liquid fuel is cyclopentadiene;

[0071] All the other are identical with embodiment 2.

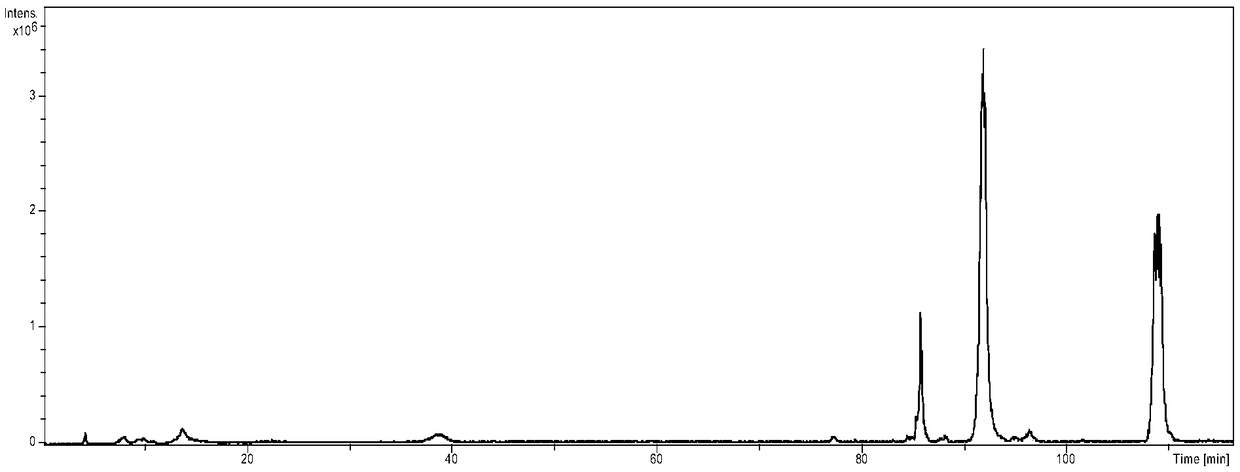

[0072] The output of solid combustion products is about 20kg / d, and the toluene extract of combustion products contains a variety of fullerenes such as C 60 and C 70 , fullerene hydrides such as C 50 h 10 and C 64 h 4 , fullerene derivatives such as C 60 (C 5 h 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com