A high-spectrum selective high-temperature solar energy absorbing coating and its preparation method

A solar energy absorption and selectivity technology, applied in the field of solar thermal, can solve the problems of large investment in continuous production lines, high production costs, harsh process conditions, etc., and achieve enhanced spectral selectivity and high temperature resistance, excellent impact resistance, The effect of low thermal emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

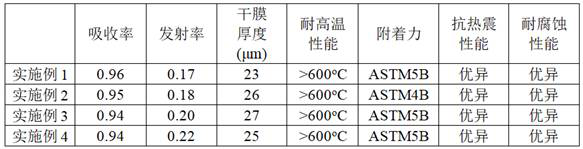

Examples

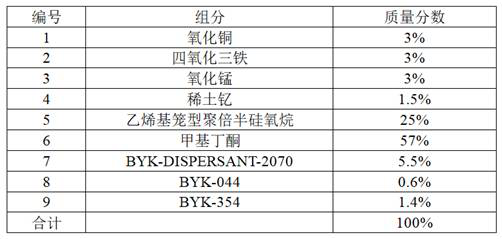

Embodiment 1

[0021] A preparation of high-spectrum selective high-temperature solar energy absorbing coating, the specific preparation method is as follows: solvent xylene, wetting and dispersing agent BYK-DISPERSANT-2070, defoamer BYK-044, leveling agent BYK-354 and high temperature resistant resin Add vinyl cage polysilsesquioxane into the container in turn, stir and disperse, and then add light-absorbing pigments (copper oxide, ferric oxide, manganese oxide, in which copper oxide is in the shape of nanorods with a diameter of 30nm and a length of 1 μm , the color is black; Fe3O4 is a nano-powder with a particle size of 80 nm and a specific surface area of 20 m 2 / g, the color is black; manganese oxide nanopowder, particle size is 70nm, specific surface area is 20 m 2 / g, color is black) and filler rare earth yttrium (particle size 30nm, specific surface area 40 m 2 / g), use a high-speed disperser, stir at a speed of 800 rpm for 50 min, and then use a sand mill or ball mill to dispers...

Embodiment 2

[0025] A preparation of high-spectrum selective high-temperature solar energy absorbing coating, the specific preparation method is as follows: solvent ethyl acetate, wetting and dispersing agent BYK-DISPERSANT-2070, defoamer BYK-044, leveling agent BYK-354 and high temperature resistant Resin trimethylsilyl cage polysilsesquioxane, etc. were added to the container in sequence, stirred and dispersed, and then light-absorbing pigments (copper oxide, ferric oxide, manganese oxide, copper oxide in the form of nanorods with a diameter of 60nm, The length is 2 μm, the color is black; Fe3O4 is nano-powder, the particle size is 30 nm, and the specific surface area is 60 m 2 / g, color is black; manganese oxide nanopowder, particle size is 30 nm, specific surface area is 90 m 2 / g, the color is black) and filler rare earth yttrium (particle size 75nm, specific surface area is 60m 2 / g), use a high-speed disperser, stir at a speed of 1000 rpm for 80 minutes, and then use a sand mill or...

Embodiment 3

[0029] A preparation of high-spectrum selective high-temperature solar energy absorbing coating, the specific preparation method is as follows: solvent xylene, wetting and dispersing agent BYK-DISPERSANT-108, defoamer BYK-044, leveling agent BYK-354 and high temperature resistant resin Add trimethylsilyl cage polysilsesquioxane into the container in turn, stir and disperse, and then add light-absorbing pigments (copper oxide, ferric oxide, manganese oxide, wherein the copper oxide is in the shape of nanorods with a diameter of 40nm and a length of 1.5 μm, the color is black; ferric oxide is a nano-powder with a particle size of 50 nm and a specific surface area of 40 m 2 / g, color is black; manganese oxide nanopowder, particle size is 60 nm, specific surface area is 50 m 2 / g, the color is black) and filler rare earth yttrium (particle size 50nm, specific surface area 45m 2 / g), use a high-speed disperser, stir at a speed of 900 rpm for 60 minutes, and then use a sand mill ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com