CoFe2O4/nitrogen-doped sludge-based activated carbon catalyst for activating persulfate to perform advanced treatment on coking wastewater and preparation method thereof

A technology for activating persulfate and advanced treatment, which is applied in physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., and can solve the problem of uneven distribution of active component nanoparticles, high equipment requirements, and catalytic Low activity and other problems, to achieve high catalytic stability and service life, enhance catalytic activity, and strengthen the effect of catalytic action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The main raw material for preparing sludge-based activated carbon—sludge is taken from the sludge thickening tank of Anshan Iron and Steel Coking Plant. The specific properties are shown in Table 1, Table 2 and Table 3:

[0049] Table 1: Basic properties of coking plant thickener sludge

[0050]

[0051] Table 2: Heavy metal content of dry sludge in thickening tank of coking plant

[0052]

[0053] Table 3: Organic content of dry sludge in thickening tank of coking plant

[0054]

[0055] A kind of CoFe activated persulfate for advanced treatment of coking wastewater 2 o 4 / Nitrogen-doped sludge-based activated carbon catalyst preparation method, comprising:

[0056] (1) Preparation of sludge-based activated carbon: Mix 10g of sludge powder and straw at a mass ratio of 3:1, add 30mL of 20% zinc chloride solution and impregnate for 16h, then activate in a tube furnace at 500°C for 2h, wash with hydrochloric acid 1. After washing with water, dry at 80°C in a ...

Embodiment 2

[0090] The same as the implementation of Example 1, when preparing sludge-based activated carbon, the mass ratio of sludge to straw was replaced by 1:1, the concentration of zinc chloride was replaced by 50%, the volume was replaced by 20mL, the soaking time was replaced by 12h, and the activation temperature was Replaced with 500°C, carbonization time replaced with 1h; preparation of CoFe 2 o 4 / N-doped sludge-based activated carbon Co(NO 3 ) 2 ·6H 2 The quality of O is replaced by 5.85g, Fe(NO 3 ) 3 9H 2 The quality of O was replaced by 16.20g, the dosage of citric acid was replaced by 12.65g, the pH was adjusted to 5 with ammonia water, the temperature of the water bath was replaced by 80°C, the dosage of sludge-based activated carbon was replaced by 18.81g, and the amount of acrylamide was replaced by Replace the amount of 10g and initiator ammonium persulfate with 0.15g, replace the firing temperature with 600°C, and replace the firing time with 1h, as follows:

[...

Embodiment 2

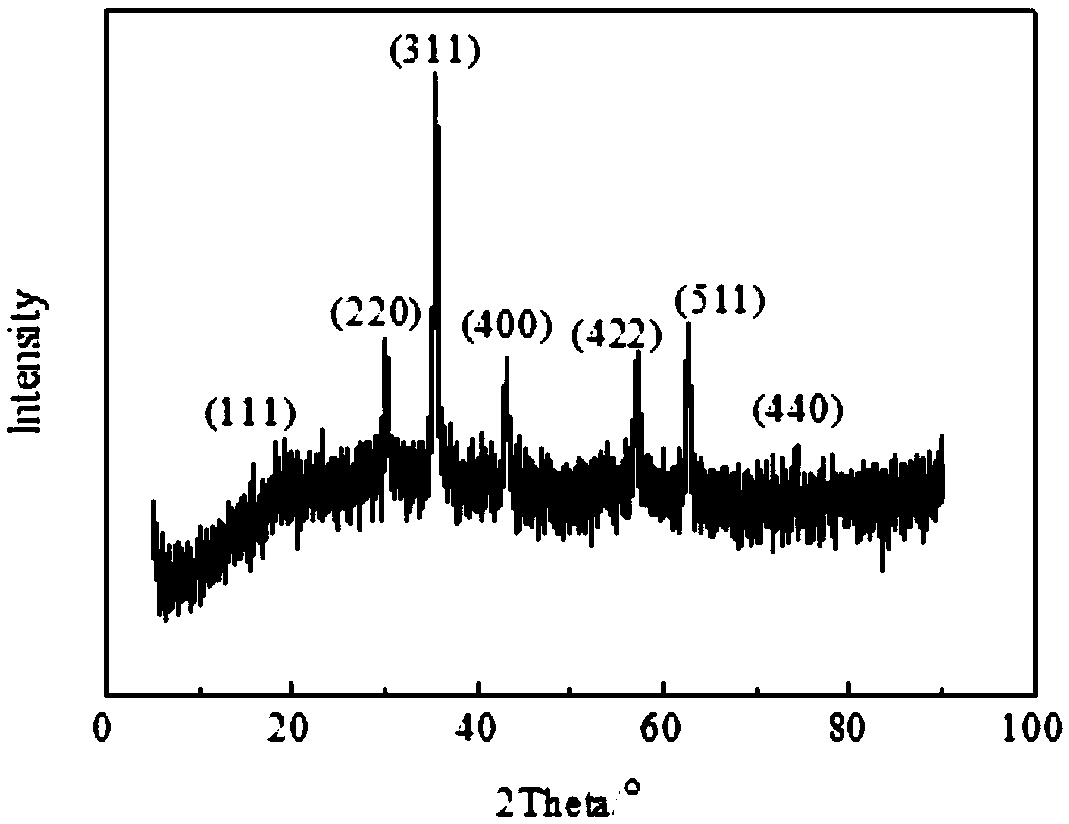

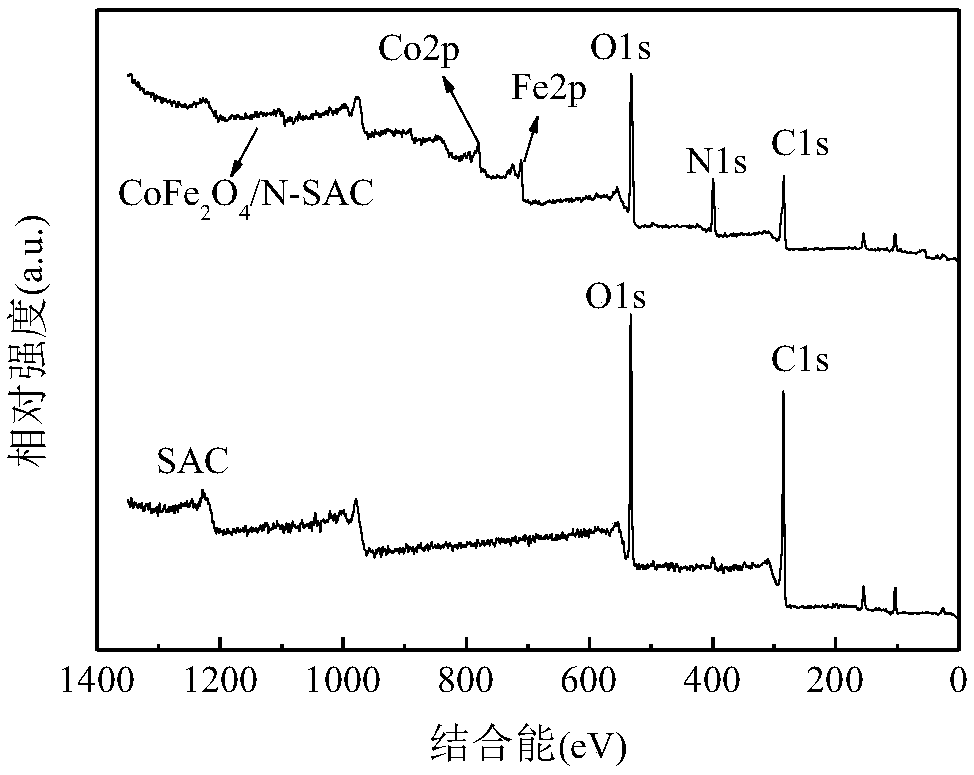

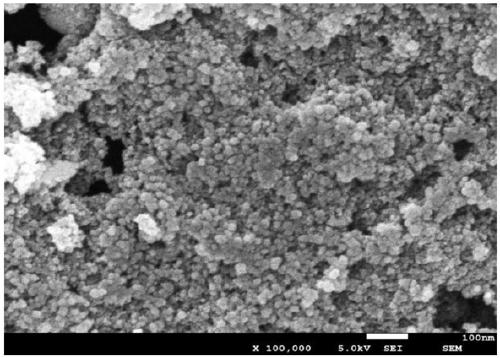

[0094] Implementation Example 2, CoFe 2 o 4 / Nitrogen-doped sludge-based activated carbon (CoFe 2 o 4 / N-SAC) and the N, O, C content of sludge-based activated carbon SAC and the XPS results of different forms of structured nitrogen content are shown in Table 6 below;

[0095] Table 6: XPS results of N, O, C content and different forms of structured nitrogen content in the catalyst

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com