Preparation method of foam plastic for solar water heater

A technology of solar water heaters and foam plastics, applied in the field of foam plastics, can solve the problems of long demoulding time, increased cost, waste of electric energy, etc., and achieve improved thermal insulation performance, waterproof and impermeable performance, wide application fields, and strong corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment relates to a kind of foamed plastics for solar water heaters, which is composed of the following raw materials in parts by weight:

[0049] 82 parts of combined polyols;

[0050] 87 parts of combined isocyanates;

[0051] 8 parts of polyethersulfone resin superfine powder;

[0052] Sea pumice powder 7 parts;

[0053] 5 parts of seaweed charcoal fiber;

[0054] 3 parts of dipropylene glycol;

[0055] 1 part of MPS emulsion;

[0056] 10 parts of pearlite;

[0057] 0.9 part of sodium dioctyl sulfosuccinate;

[0058] Butanone 2 parts;

[0059] 1.5 parts of trihydroxymethyl phosphine oxide;

[0060] 1 part foaming agent;

[0061] 0.6 parts of coupling agent;

[0062] 0.8 parts of crosslinking agent;

[0063] Catalyst 0.3 parts.

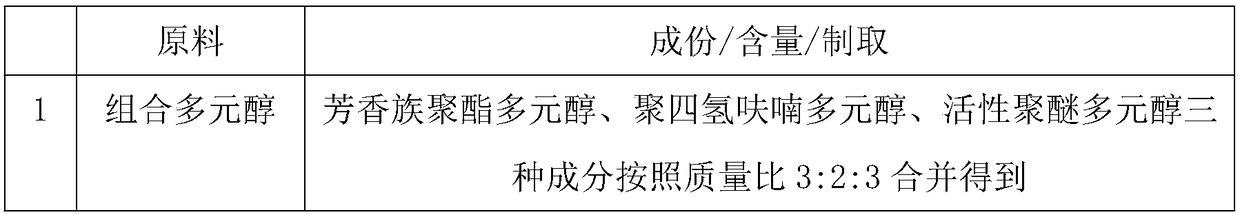

[0064] The selection and preparation of some raw materials in the present embodiment are shown in Table 1 below:

[0065] Table 1

[0066]

[0067]

[0068] The preparation method of foamed plastics generally carr...

Embodiment 2

[0074] This embodiment relates to a kind of foamed plastics for solar water heaters, which is composed of the following raw materials in parts by weight:

[0075] 88 parts of combined polyols;

[0076] 94 parts of combined isocyanates;

[0077] 9 parts of polyethersulfone resin superfine powder;

[0078] Sea pumice powder 9 parts;

[0079] 6 parts of seaweed charcoal fiber;

[0080] 4 parts of dipropylene glycol;

[0081] 1.5 parts of MPS emulsion;

[0082] 13 parts of pearlite;

[0083] 1.1 parts of sodium dioctyl sulfosuccinate;

[0084] Butanone 3 parts;

[0085] 2 parts of trihydroxymethyl phosphine oxide;

[0086] 1.2 parts of blowing agent;

[0087] 0.8 parts of coupling agent;

[0088] 1 part of cross-linking aid;

[0089] Catalyst 0.75 parts.

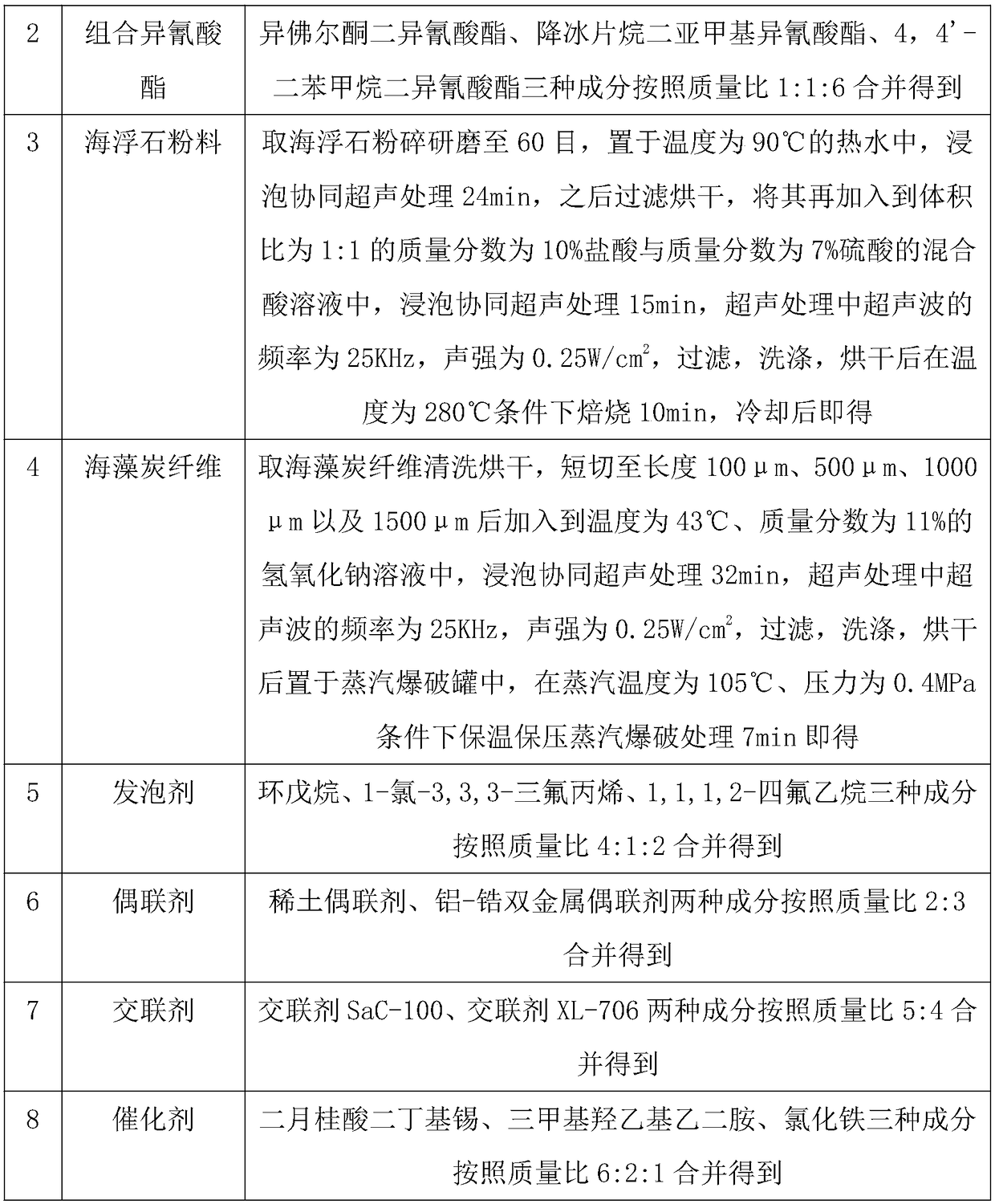

[0090] The selection and preparation of some raw materials in this embodiment are shown in Table 2 below:

[0091] Table 2

[0092]

[0093] The preparation method of foamed plastics generally carries out accord...

Embodiment 3

[0099] This embodiment relates to a kind of foamed plastics for solar water heaters, which is composed of the following raw materials in parts by weight:

[0100] 94 parts of combined polyols;

[0101] 101 parts of combined isocyanates;

[0102] 10 parts of polyethersulfone resin superfine powder;

[0103] Sea pumice powder 11 parts;

[0104] 7 parts of seaweed charcoal fiber;

[0105] 5 parts of dipropylene glycol;

[0106] 2 parts of MPS emulsion;

[0107] 15 parts of pearl sand;

[0108] 1.3 parts of sodium dioctyl sulfosuccinate;

[0109] Butanone 3.5 parts;

[0110] 2.5 parts of trihydroxymethyl phosphorus oxide;

[0111] 1.5 parts of blowing agent;

[0112] 1 part of coupling agent;

[0113] 1.2 parts of crosslinking agent;

[0114] Catalyst 1.2 parts.

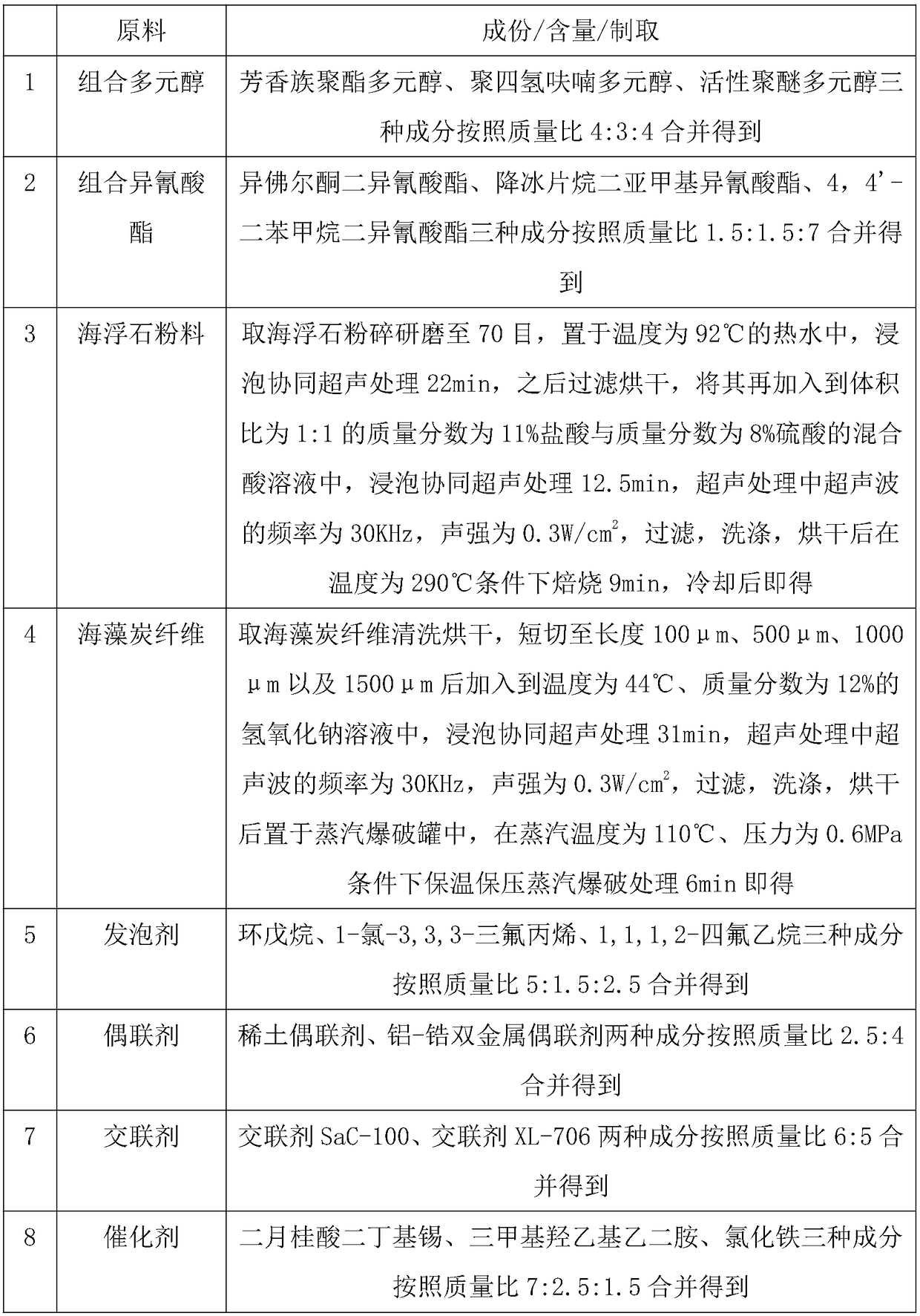

[0115] The selection and preparation of some raw materials in the present embodiment are shown in Table 3 below: Table 3

[0116]

[0117] The preparation method of foamed plastics generally carries out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com