Cathodic micro-arc oxidation solution and method for preparing DLC composite oxidation film on steel surface

A technology of composite oxide film and cathode micro-arc, which is applied in anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc. Density and other issues, to achieve the effect of increased hardness, increased growth rate, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

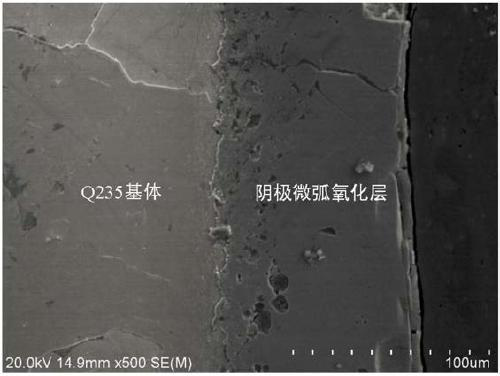

[0017] In this example, the processed steel material is Q235 low carbon steel sample.

[0018] Firstly, the steel material to be treated is pretreated, and the steel surface is pretreated step by step with sandpaper (200#-1200#), rinsed with acetone, rinsed with deionized water and dried.

[0019] Then configure the cathodic micro-arc oxidation solution. The cathodic micro-arc oxidation solution is: methanol 200mL, ethanolamine 200mL, urea 210g, nickel sulfate 15g, nano-carbon powder 20g, sodium chloride 100g, deionized water 450mL.

[0020] After the electrolyte is prepared, immerse the two electrodes in the electrolytic cell equipped with the prepared electrolyte, ventilate and stir; quickly raise the voltage to 420V at room temperature and keep it for 12 minutes.

[0021] After the above steps, the Q235 low-carbon steel whose surface is covered with a uniform DLC composite oxide film is finally obtained.

[0022] The workpiece was cut and mounted with bakelite powder. Aft...

Embodiment 2

[0024] According to the same method as in Example 1, the Q235 low-carbon steel sample was pretreated, the electrolyte was prepared, and the low-carbon steel was subjected to cathodic micro-arc oxidation treatment. The difference from Example 1 is that in this example, the electrolyte components are methanol 240mL, ethanolamine 300mL, urea 200g, nickel sulfate 15g, nano carbon powder 15g, sodium chloride 80g, deionized water 560mL. Apply a voltage of 350V for 4 minutes.

[0025] After the above steps, the Q235 low-carbon steel whose surface is covered with a uniform DLC composite oxide film is finally obtained. The thickness of the composite oxide film measured by the same method as in Example 1 was 25 μm, and the microhardness of the film layer was 610 HV.

Embodiment 3

[0027] According to the same method as in Example 1, the Q235 low-carbon steel sample was pretreated, the electrolyte was prepared, and the low-carbon steel was subjected to cathodic micro-arc oxidation treatment. The difference is that in this example, 280mL of methanol, 200mL of ethanolamine, 300g of urea, 15g of nickel sulfate, 30g of nano-carbon powder, 100g of sodium chloride, and 450mL of deionized water are contained in the electrolyte. Apply a voltage of 520V for 12 minutes.

[0028] After the above steps, the Q235 low-carbon steel whose surface is covered with a uniform DLC composite oxide film is finally obtained. The thickness of the composite oxide film measured by the same method as in Example 1 was 100 μm, and the microhardness of the film layer was 1150 HV.

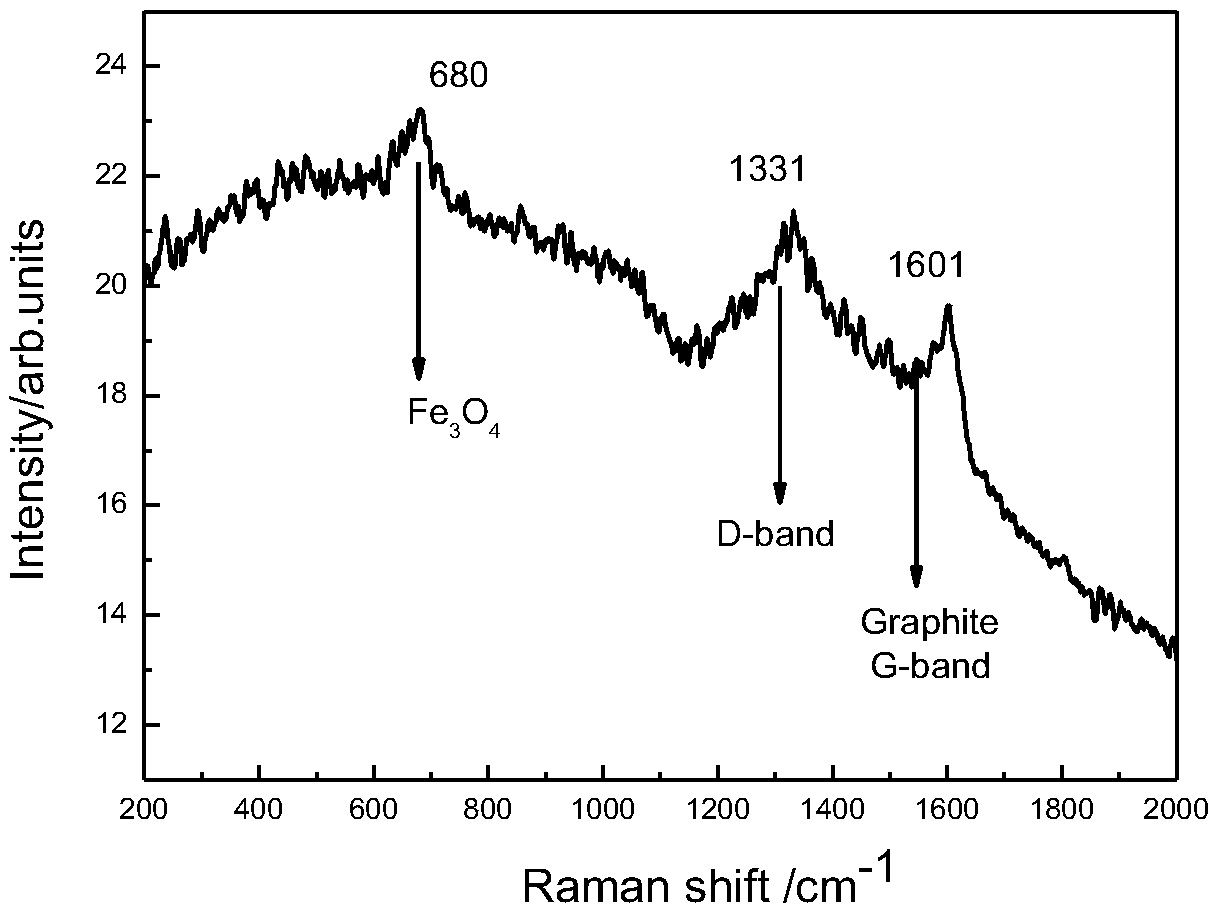

[0029] The Raman spectrum of the DLC composite oxide film was detected by a Horiba LabRAM Aramis Raman spectrometer, and it was determined that the film layer contained diamond-like carbon (DLC) components...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com