Porous carbon nano-tube flexible battery material containing nano-silicon and preparation method thereof

A flexible battery and flexible material technology, applied in the direction of secondary batteries, battery electrodes, active material electrodes, etc., to achieve the effect of increasing the specific surface area, reducing the transmission distance, and controlling the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

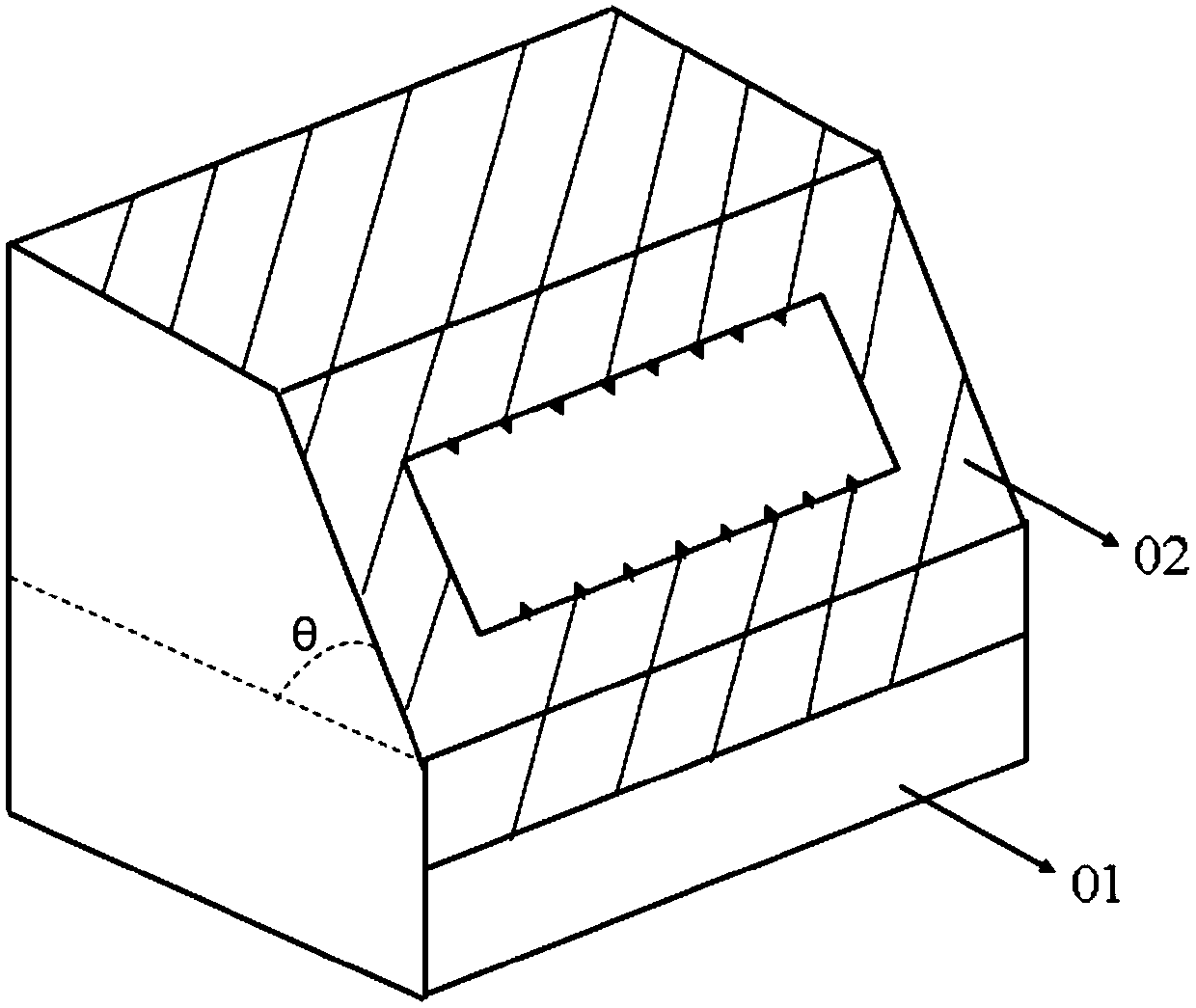

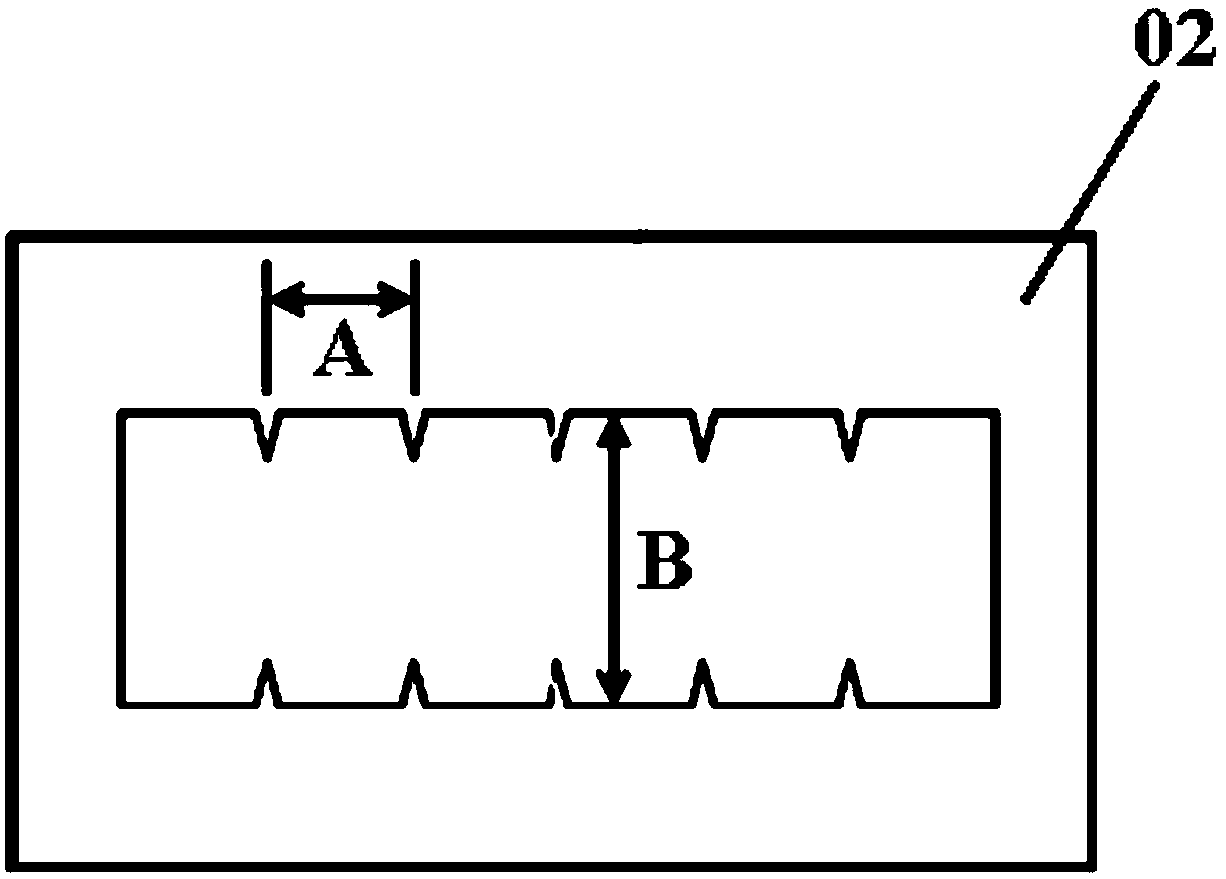

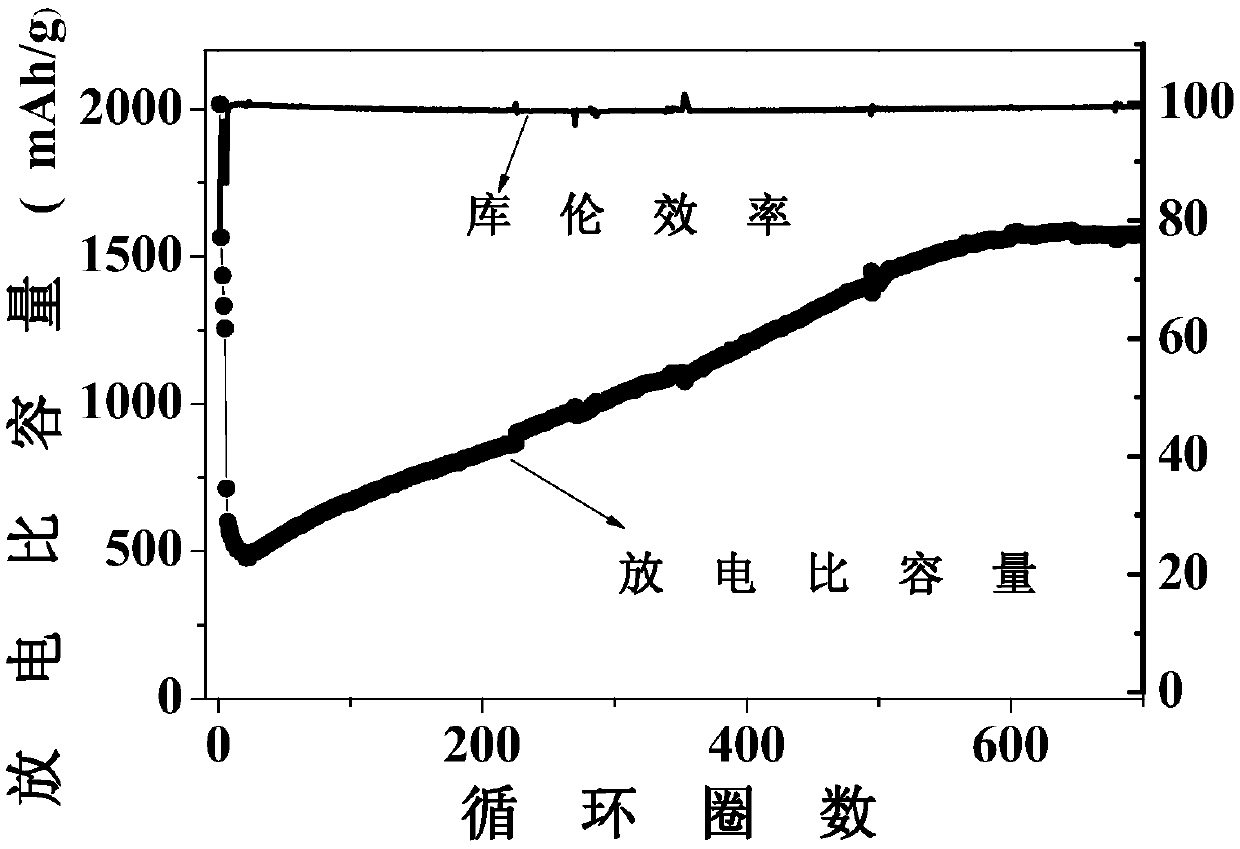

[0037]First, 0.25g of silane coupling agent HK560 and 0.5g of fumed silica (with a particle size of 50-500nm) were refluxed in 100mL of ethanol at 90°C for 4 hours for surface modification treatment; then 1.15g of polyacrylonitrile, 0.05 Add g polymethyl methacrylate to 10mL organic solvent N,N dimethylformamide, heat and stir at 60°C for 60min until dissolved; then add surface-modified fumed silica particles, and disperse evenly by ultrasonic to obtain spinning silk slurry; after the above-mentioned spinning solution is removed from the small vacuoles, pass through a high-voltage electrospinning machine at 20KV, the needle point and the receiving device (the receiving device is a zigzag receiving device, and its structural diagram is as follows: figure 1 As shown, it is composed of a zigzag receiving plate 02 made of aluminum or copper supported by a polymethyl methacrylate (PMMA) substrate 01 , and the inclination angle θ of the zigzag receiving plate 02 to the horizontal dir...

Embodiment 2

[0040] First, 0.5g of silane coupling agent HK560 and 0.5g of water glass hydrolyzed silica (with a particle size of 50-500nm) were refluxed in 100mL of ethanol at 90°C for 4 hours for surface modification treatment; then 1.15g of polyacrylonitrile , Add 0.1g polymethyl methacrylate to 10mL organic solvent N,N dimethylformamide, heat and stir at 60°C for 60min until dissolved; then add surface-modified water glass hydrolyzed silica particles, and ultrasonically Disperse to obtain the spinning slurry; after the above-mentioned spinning solution is removed from the small bubbles, pass through the high-voltage electrospinning machine at 20KV, the needle point and the receiving device (the receiving device is a zigzag receiving device, and its structural diagram is as follows: figure 1 and figure 2 As shown), the distance of 25cm, the blunt needle pushing speed of 0.035ml / min, the humidity of the spinning process is 35% to 40%, and the temperature of the spinning process is 20 to...

Embodiment 3

[0043] First, 1g of silane coupling agent HK560 and 0.5g of tetraethyl orthosilicate hydrolyzed silica (particle size 50-500nm) were refluxed in 100mL of ethanol at 90°C for 4 hours for surface modification treatment; then 1.15g of poly Add acrylonitrile and 0.12g polylactic acid to 10mL organic solvent N,N dimethylformamide, heat and stir at 60°C for 60min until dissolved; then add surface-modified ethyl orthosilicate hydrolyzed silica particles, ultrasonic Uniformly disperse to obtain spinning slurry; after the above-mentioned spinning solution is removed from small bubbles, pass through a high-voltage electrospinning machine at 20KV, the needle point and the receiving device (the receiving device is a zigzag receiving device, and its structural diagram is as follows: figure 1 and figure 2 As shown), the distance of 25cm, the blunt needle pushing speed of 0.035ml / min, the humidity of the spinning process is 35% to 40%, and the temperature of the spinning process is 20 to 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com