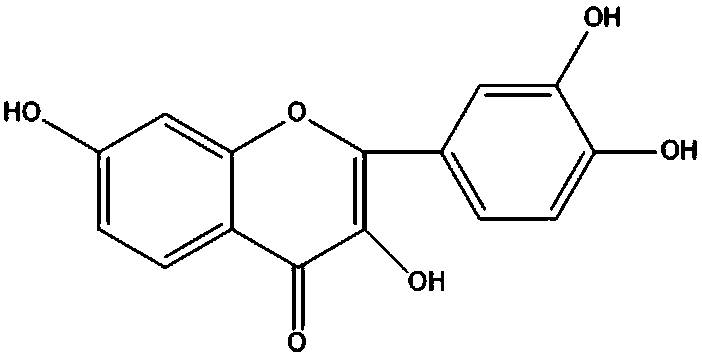

Synthesis method of fisetin

A synthetic method, the technology of fisetin, applied in the direction of organic chemistry, etc., can solve the problems that the product yield and content cannot be obtained at the same time, and the synthesis of fisetin is only suitable, so as to reduce the felling of boxwood, low production cost, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

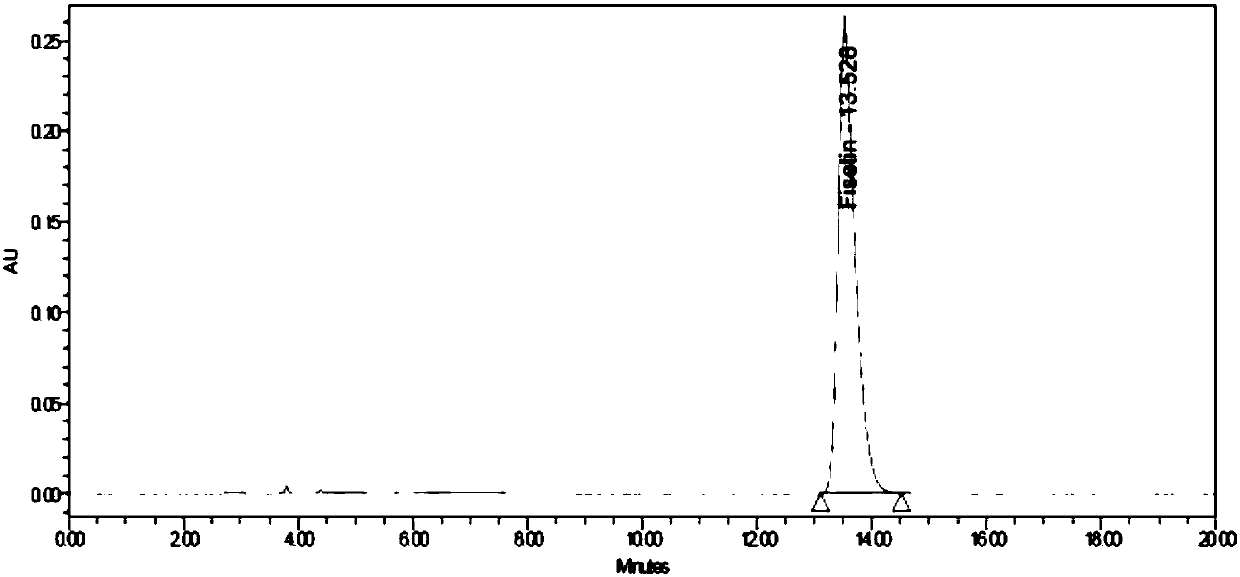

Examples

Embodiment 1

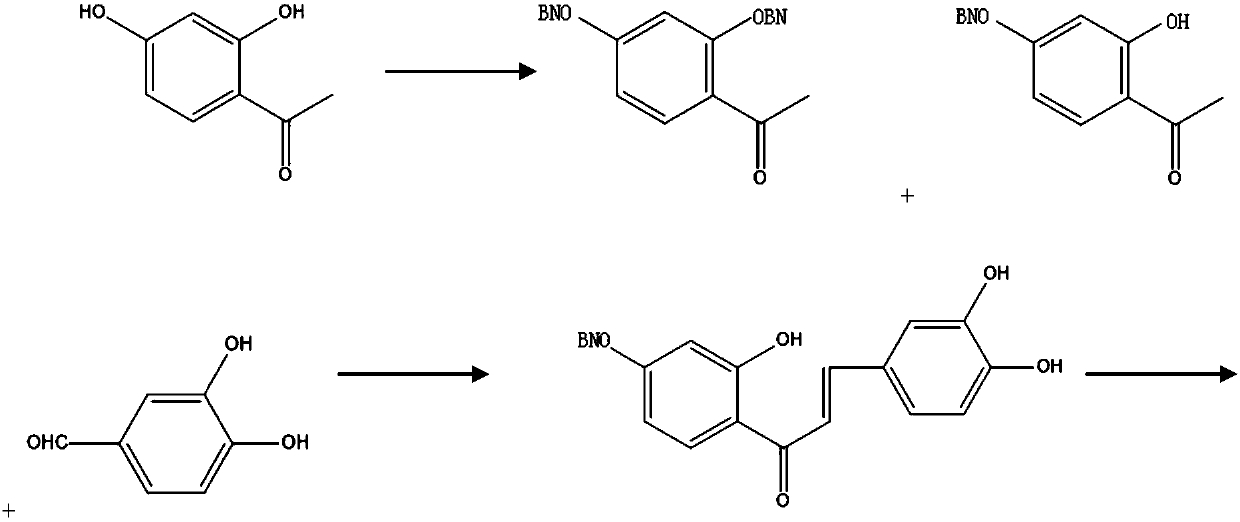

[0052] A synthetic method for fisetin, comprising the following steps:

[0053] Step 1) Produces a white mixture

[0054] 1.1) Stir 100ml of 2-butanone and 24g of benzyl chloride evenly, then add 8g of 2,4-dihydroxyacetophenone and 25g of anhydrous K 2 CO 3 , stirring, after heating and reflux reaction for 12h, add 100ml of water and stir;

[0055] 1.2) After the reaction is finished, extract with dichloromethane, evaporate the solvent by rotary evaporation, and collect the residue; and recrystallize the residue with 20ml of methanol to obtain 13.6g of white mixture powder with a yield of 75.1%.

[0056] Step 2) generate 3', 4'-dihydroxy-7-benzylchalcone

[0057] 2.1) Dissolve 13.6g of white mixture powder and 13.5g of protocatechualdehyde into 100ml of absolute ethanol, add 120g of potassium hydroxide solution with a mass concentration of 30%, stir under nitrogen protection, heat up and reflux for about 20h , cooled and poured into 150g of ice water to quench the reaction...

Embodiment 2

[0067] A synthetic method for fisetin, comprising the following steps:

[0068] Step 1) Produces a white mixture

[0069] 1.1) Stir 120ml of 2-butanone and 29g of benzyl chloride evenly, then add 9.6g of 2,4-dihydroxyacetophenone and 30g of anhydrous K 2 CO 3 , after heating up to reflux for 12 hours, add 121ml of water and stir;

[0070] 1.2) After the reaction is finished, extract with dichloromethane, evaporate the solvent by rotary evaporation, and collect the residue; and recrystallize the residue with 20ml of methanol to obtain 15.6g of white mixture powder with a yield of 75.1%.

[0071] Step 2) generate 3', 4'-dihydroxy-7-benzylchalcone

[0072] 2.1) Dissolve 15.6g of white mixture powder and 15.5g of protocatechualdehyde into 120ml of absolute ethanol, add 150g of potassium hydroxide solution with a mass concentration of 30%, and stir and heat up to reflux for about 20h under nitrogen protection. Cool and pour into 180g of ice water to quench the reaction;

[007...

Embodiment 3

[0082] A synthetic method for fisetin, comprising the following steps:

[0083] Step 1) Produces a white mixture

[0084] 1.1) Stir 50ml of 2-butanone and 12g of benzyl chloride evenly, then add 4g of 2,4-dihydroxyacetophenone and 13g of anhydrous K 2 CO 3 , after heating and reflux reaction for 12h, add 50ml of water and stir;

[0085] 1.2) After the reaction is finished, extract with dichloromethane, evaporate the solvent by rotary evaporation, and collect the residue; and recrystallize the residue with 20ml of methanol to obtain 6.5g of white mixture powder with a yield of 74.5%.

[0086] Step 2) generate 3', 4'-dihydroxy-7-benzylchalcone

[0087] 2.1) Dissolve 6.5g of white mixture powder and 6.5g of protocatechualdehyde into 50ml of absolute ethanol, add 60g of potassium hydroxide solution with a mass concentration of 30%, and stir and heat up to reflux for about 20h under nitrogen protection. Cool and pour into 80g of ice water to quench the reaction;

[0088] 2.2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com