Iron-copper bimetal particle and preparation method thereof, and treatment method for dinitrodiazophenol wastewater

A technology of dinitrodiazophenol and a treatment method is applied in the field of treatment of dinitrodiazophenol wastewater, which can solve the problems of narrow pH applicable range, short service life of raw materials, corrosion and consumption, etc., so as to achieve improvement and reuse. The effect of utilization, low production cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

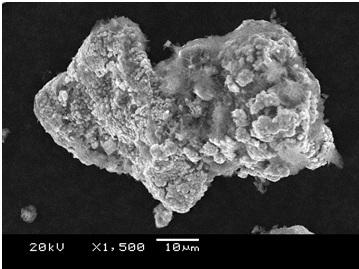

[0059] At room temperature, normal pressure and a stirring speed of 500r / min, iron powder with an average particle size of about 50 µm was added to an aqueous solution of copper sulfate with a copper ion concentration of 10 mg / L, and the amount added was iron powder and copper ion The mass ratio of the mixture was 10:2, and then continued to stir for 15 minutes, then allowed to settle for 15 minutes, and then discharged the supernatant, and washed the obtained solid particles with deionized water to remove salt impurities on the surface, and then under the protection of nitrogen in the Dry at 40°C until there is no moisture on the surface to obtain iron-copper bimetallic particles. figure 1 It can be observed from the scanning electron microscope image that the particle size of the obtained iron-copper bimetallic particles is about 50~60μ, which is composed of iron particles and copper particles, and the copper particles are evenly distributed and adhered to the surface of the ...

Embodiment 2

[0061] At room temperature, normal pressure and a stirring speed of 600r / min, iron powder with an average particle size of about 800µm was added to industrial wastewater with a copper ion concentration of 12mg / L, and the amount added was the mass ratio of iron powder to copper ion 10:1, then continue to stir for 20 minutes, and then let it settle for 5 minutes to discharge the supernatant, wash the obtained solid particles with deionized water to remove salt impurities on the surface, and then dry at 40°C under the protection of nitrogen When there is no moisture on the surface, iron-copper bimetallic particles are obtained. The particle size is about 800~850μm, which is observed by scanning electron microscope. It is composed of iron particles and copper particles, and the copper particles are evenly distributed and adhered to the surface of the iron particles. .

Embodiment 3

[0063] At room temperature, normal pressure and a stirring speed of 600r / min, iron powder with an average particle size of 100 µm was added to copper sulfite aqueous solution with a copper ion concentration of 14 mg / L, and the amount of iron powder and copper ion added was The mass ratio is 10:1, then continue to stir for 20 minutes, then let it settle for 20 minutes and then discharge the supernatant, wash the obtained solid particles with deionized water to remove salt impurities on the surface, and then dry them under vacuum at room temperature When there is no moisture on the surface, iron-copper bimetallic particles are obtained. The particle size is about 100-150 μm, which is observed by scanning electron microscopy. It is composed of iron particles and copper particles, and the copper particles are evenly distributed and adhered to the surface of the iron particles. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com