Positive electrode material and preparation method and battery

A positive electrode material and spinel technology, which is applied to the preparation method thereof and the fields of batteries and positive electrode materials, can solve problems such as the danger of flatulence of batteries, and achieve the effects of increasing gram capacity, increasing conductivity and reducing electronic conduction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

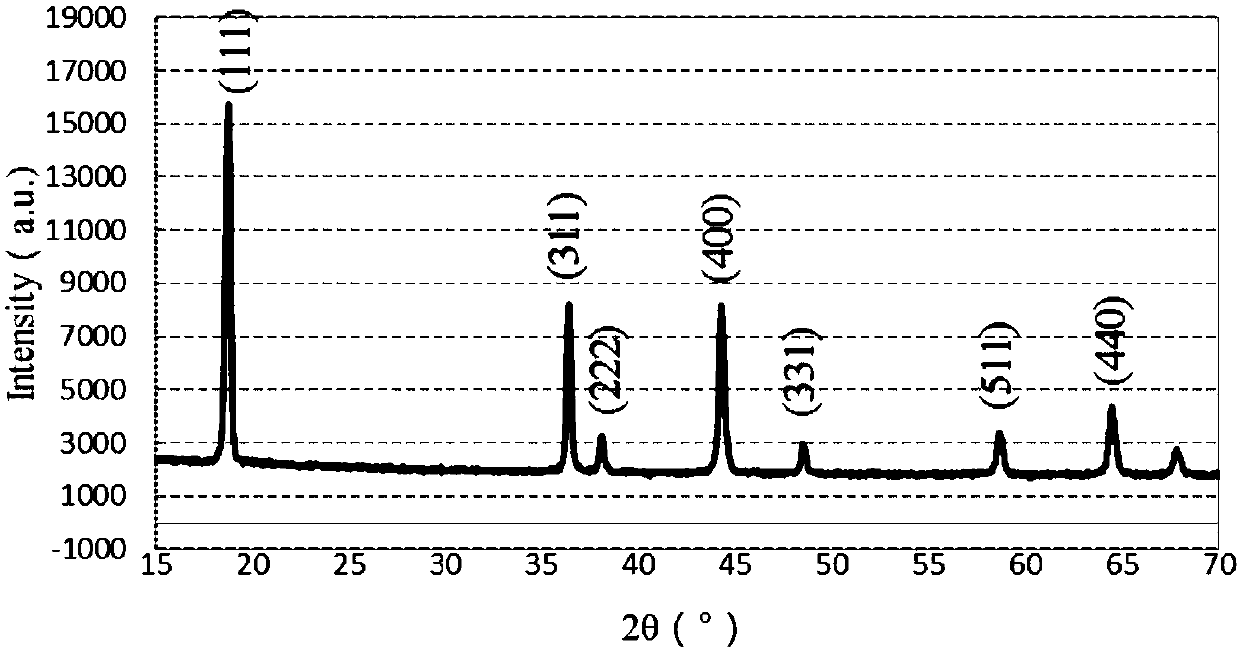

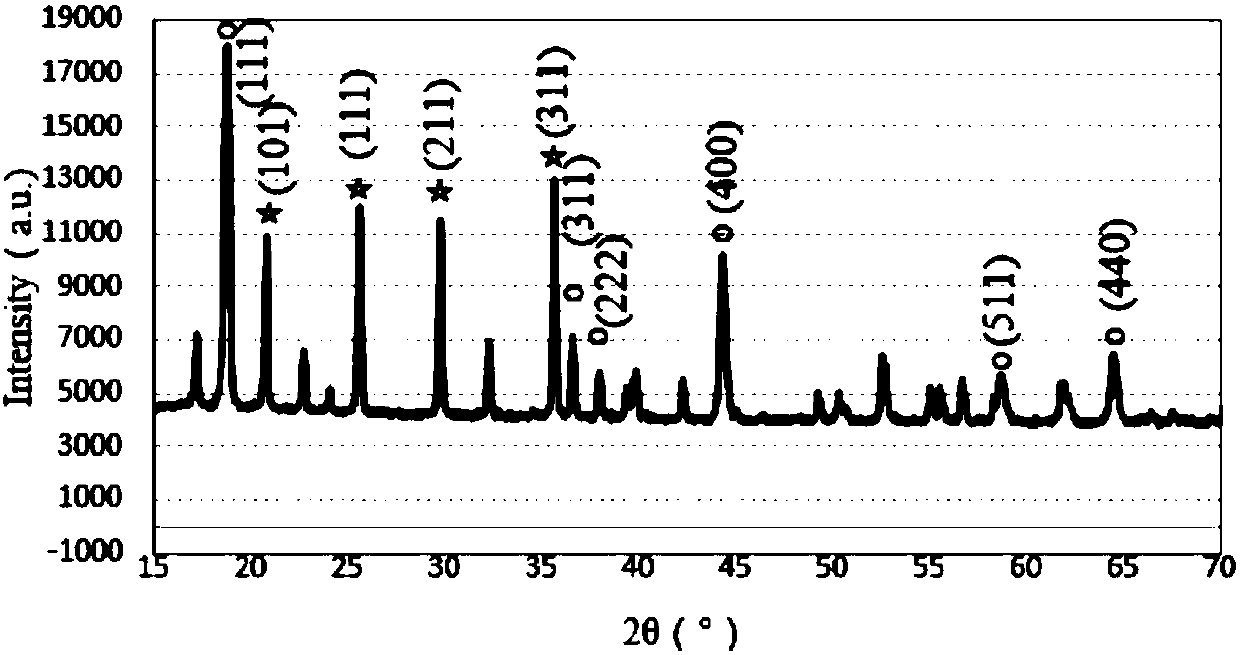

Image

Examples

preparation example Construction

[0023] The second aspect of the embodiments of the present invention provides a method for preparing a positive electrode material, at least including the following steps:

[0024] Step 1: Mix the lithium source, nickel source, manganese source and doping metal source of spinel lithium nickel manganese oxide and sinter to generate the spinel lithium nickel manganese oxide;

[0025] Step 2: Mix the lithium source, phosphorus source, iron source and carbon source of lithium iron phosphate with spinel lithium nickel manganese oxide and then granulate to obtain the precursor;

[0026] Step 3: Sintering the precursor to obtain the positive electrode material.

[0027] Optionally, in step 1, when sintering spinel lithium nickel manganese oxide, the lithium source of spinel lithium nickel manganese oxide is selected from at least one of lithium carbonate, lithium hydroxide, lithium nitrate, and lithium chloride , not limited thereto; and further optional lithium hydroxide monohydrat...

experiment example

[0089] 1. Residual lithium (Li + )Comparative Experiment

[0090] Get the cathode material that embodiment 1-7 and comparative example 1-3 prepare, under the same condition carry out residual lithium (Li + )Comparative Experiment.

[0091] Residual lithium (Li + ) amount comparison test method is the acid-base titration method: titrate lithium carbonate and lithium hydroxide in the positive electrode material with hydrochloric acid standard solution, use the pH electrode as the indicator electrode, determine the end point by means of the sudden jump generated by the potential change, and calculate the residual amount on the surface of the positive electrode material. lithium amount.

[0092] The obtained experimental results are shown in Table 4.

[0093] Table 4

[0094] project

unit

Example 1

Example 2

Example 3

Example 4

Example 5

Li +

%(w / w)

0.0810

0.0832

0.0737

0.0813

0.0734

project

unit

Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com