Method for purifying and deodorizing wastewater generated in fermented cordyceps taishanensis powder production process

A technology for fermenting Cordyceps fungus powder and production process, which is applied in chemical instruments and methods, neutralizing water/sewage treatment, water pollutants, etc., and can solve problems such as difficult to achieve treatment capacity, heavy odor, and excessive waste water quality control indicators. , to achieve the effect of improving processing capacity, reducing emission treatment costs, and improving the level of online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

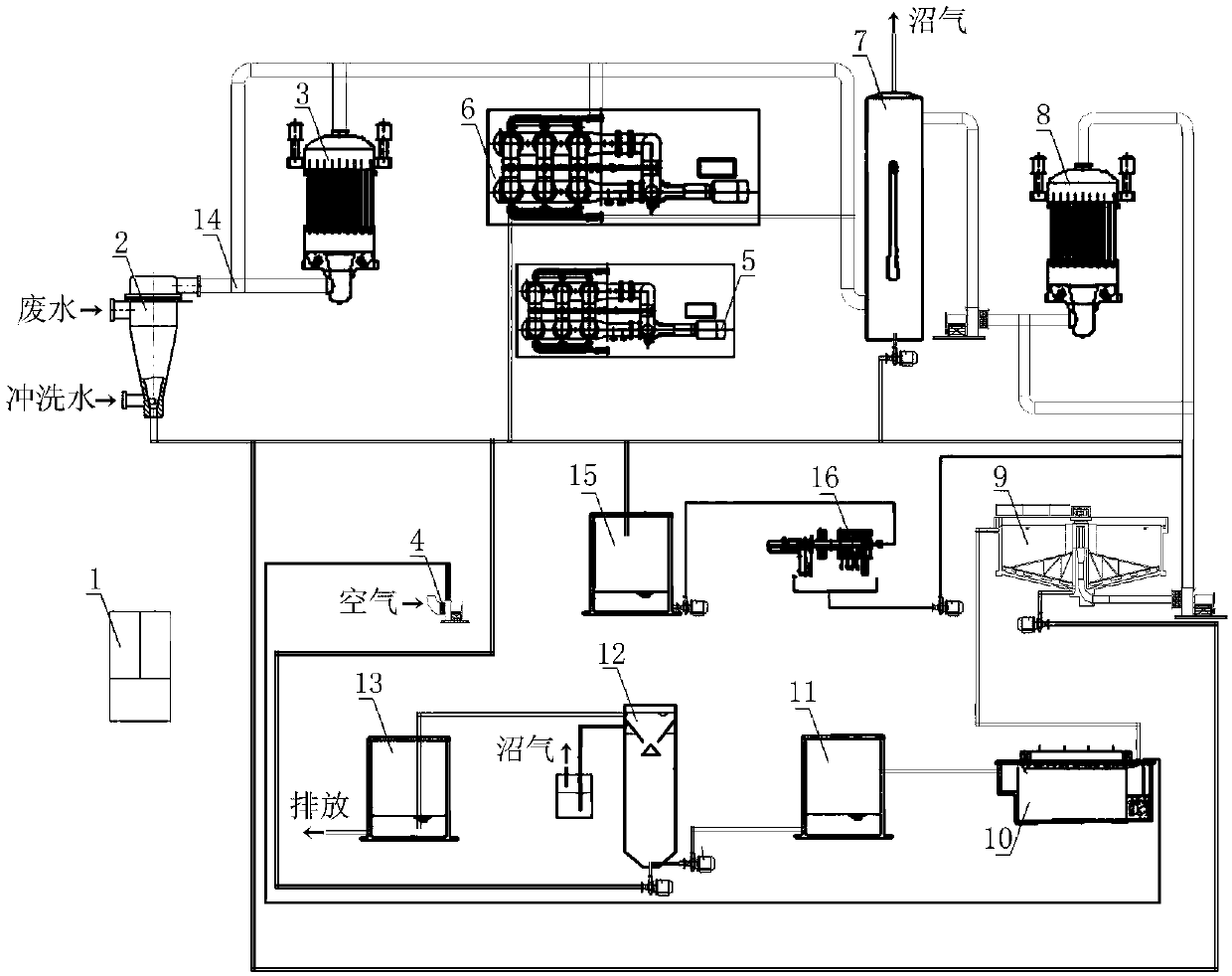

Method used

Image

Examples

Embodiment 1

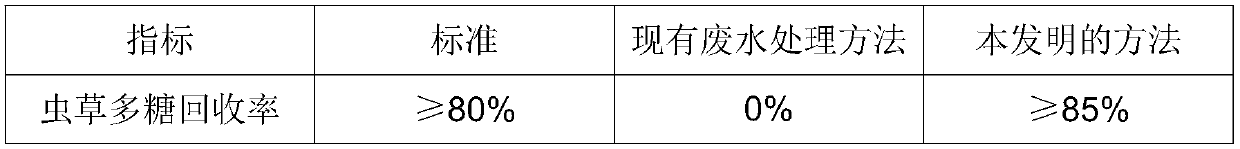

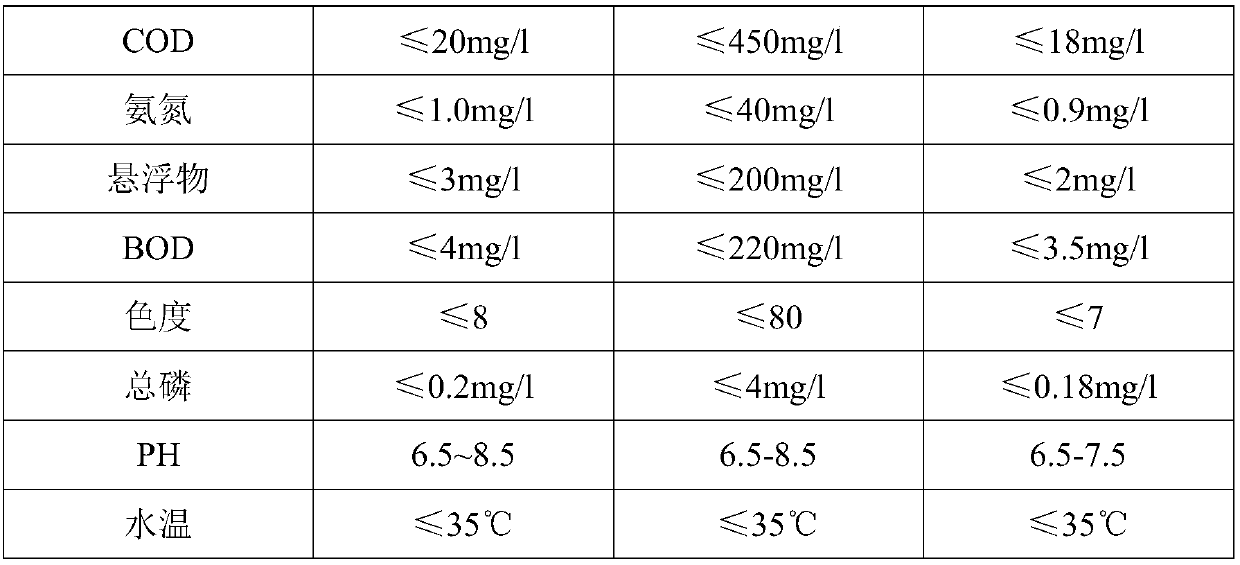

[0037] 1) Set the start-up temperature of the heat exchange system at 40°C, and the average dosage of coagulant in the settling tank is: PAM: 5mg / l; PAC: 125mg / l. The chemical reagents in the adjustment tank are sodium hypochlorite and sodium hydroxide in turn; the initial concentrations of the chemical reagents are 7% and 10% in turn. The main pollutant discharge standards of the treated water body are: COD: ≤20mg / l; ammonia nitrogen: ≤1.0mg / l; SS: ≤3mg / l; BOD: ≤4mg / l; chroma: ≤8; total phosphorus: ≤ 0.2mg / l; PH: 6.5~8.5; water temperature: ≤35℃.

[0038] 2) After the waste water from the fermentation tank produced in the production process of the fermented Cordyceps powder is separated by the cyclone separator, the deslagging waste water enters the waste water monitoring buffer room equipped with temperature and waste water concentration monitoring sensors. According to the monitoring data of the monitoring sensors, the solenoid valve is automatically controlled And the wat...

Embodiment 2

[0041] 1) Set the start-up temperature of the heat exchange system at 40°C, and the average dosage of coagulant in the settling tank is: PAM: 5mg / l; PAC: 125mg / l. The chemical reagents in the adjustment tank are sodium hypochlorite and sodium hydroxide in turn; the initial concentrations of the chemical reagents are 7% and 10% in turn. The main pollutant discharge standards of the treated water body are: COD: ≤20mg / l; ammonia nitrogen: ≤1.0mg / l; SS: ≤3mg / l; BOD: ≤4mg / l; chroma: ≤8; total phosphorus: ≤ 0.2mg / l; PH: 6.5~8.5; water temperature: ≤35℃.

[0042] 2) After the fermentation filtrate produced by the extraction post of fermented Cordyceps powder is separated by the cyclone separator, the deslagging wastewater enters the wastewater monitoring buffer room equipped with temperature and wastewater concentration monitoring sensors. According to the monitoring data of the monitoring sensors, the self-control solenoid valve and water pump will Deslagging wastewater selectively...

Embodiment 3

[0045] 1) Set the start-up temperature of the heat exchange system at 40°C, and the average dosage of coagulant in the settling tank is: PAM: 5mg / l; PAC: 125mg / l. The chemical reagents in the adjustment tank are sodium hypochlorite and sodium hydroxide in turn; the initial concentrations of the chemical reagents are 7% and 10% in turn. The main pollutant discharge standards of the treated water body are: COD: ≤20mg / l; ammonia nitrogen: ≤1.0mg / l; SS: ≤3mg / l; BOD: ≤4mg / l; chroma: ≤8; total phosphorus: ≤ 0.2mg / l; PH: 6.5~8.5; water temperature: ≤35℃.

[0046] 2) After the environmental cleaning wastewater produced in the production process of fermented Cordyceps powder is separated by the cyclone separator, the deslagging wastewater enters the wastewater monitoring buffer room equipped with temperature and wastewater concentration monitoring sensors. According to the monitoring data of the monitoring sensors, the self-control solenoid valve and The water pump selectively passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com