Quick preparation method of water glass based fiber reinforced SiO2 aerogel block

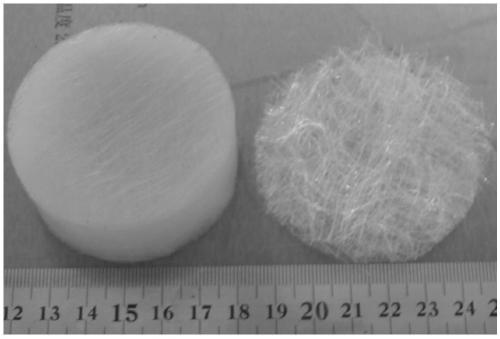

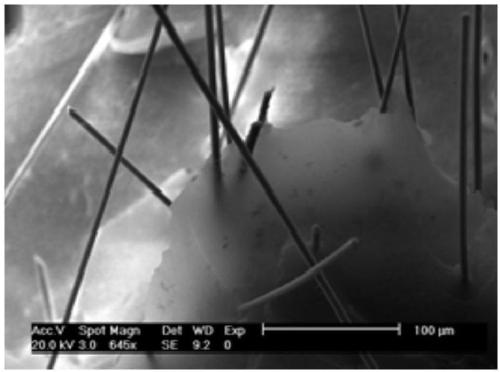

A fiber-reinforced, glass-fiber technology is applied in the field of rapid preparation of water glass-based fiber-reinforced SiO2 aerogel blocks, and can solve the problems of difficult to achieve large-scale continuous production, large solvent consumption, and low mechanical strength. , to achieve the effect of promoting industrial production and market application, simple process route and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

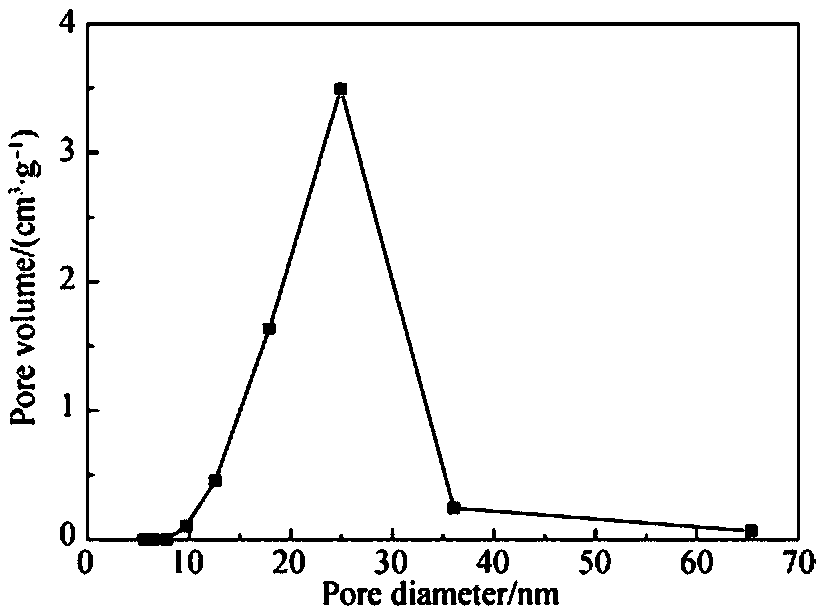

Embodiment 1

[0045] At first, industrial grade water glass (purity 55.1%, the molar ratio of solution substance is n(Na 2 O):n(SiO 2 ) = 1:3.1) and deionized water in a molar ratio of 0.015 and stirred until uniform. At room temperature, the mixed solution is passed through an exchange column filled with a strong acid styrene cation exchange resin to remove sodium, potassium and other cations present in the water glass, and the solution after the exchange treatment is acidic with a pH value of 4. Subsequently, a sodium hydroxide reagent with a concentration of 0.1 mol / L was added to adjust the pH value of the solution to 5.5 to form SiO 2 Sol.

[0046] The formed SiO 2 Stirring of the sol was continued for 25 minutes, after which the sol was poured into a polytetrafluoroethylene-lined, stainless steel-encased hydrothermal kettle filled with fibers. The hydrothermal kettle is placed in a thermostat at a certain temperature and kept warm for 6 hours. After the process was completed, the...

Embodiment 2

[0053] At first, industrial grade water glass (purity 55.1%, the molar ratio of solution substance is n(Na 2 O):n(SiO 2 ) = 1:3.1) and deionized water in a molar ratio of 0.02 and stirred until uniform. At room temperature, the mixed solution is passed through an exchange column filled with a strong acid styrene cation exchange resin to remove sodium, potassium and other cations present in the water glass, and the solution after the exchange treatment is acidic with a pH value of 4. Subsequently, a sodium hydroxide reagent with a concentration of 0.1 mol / L was added to adjust the pH value of the solution to 7 to form SiO 2 Sol.

[0054] The formed SiO 2 The sol was continuously stirred for 25 minutes, and after stirring, the sol was poured into a hydrothermal kettle with a stainless steel shell lined with polytetrafluoroethylene lined with fibers. The hydrothermal kettle was placed in a thermostat at a certain temperature and kept warm for 6 hours. After the process was c...

Embodiment 3

[0061] At first, industrial grade water glass (purity 55.1%, the molar ratio of solution substance is n(Na 2 O):n(SiO 2 ) = 1:3.1) and deionized water in a molar ratio of 0.03 and stirred until uniform. At room temperature, the mixed solution is passed through an exchange column filled with a strong acid styrene cation exchange resin to remove sodium, potassium and other cations present in the water glass, and the solution after the exchange treatment is acidic with a pH value of 4. Subsequently, a sodium hydroxide reagent with a concentration of 0.1 mol / L was added to adjust the pH value of the solution to 7 to form SiO 2 Sol.

[0062] The formed SiO 2 The sol was continuously stirred for 25 minutes, and after stirring, the sol was poured into a hydrothermal kettle with a stainless steel shell lined with polytetrafluoroethylene lined with fibers. The hydrothermal kettle was placed in a thermostat at a certain temperature and kept warm for 6 hours. After the process was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com