Antibacterial and flame-retardant polypropylene composite material

A technology of flame-retardant polypropylene and composite materials, applied in the field of composite materials, can solve the problems of threatening the health of users and the breeding of various pathogenic bacteria, etc., and achieve the effects of improving mechanical properties, increasing crystallinity, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

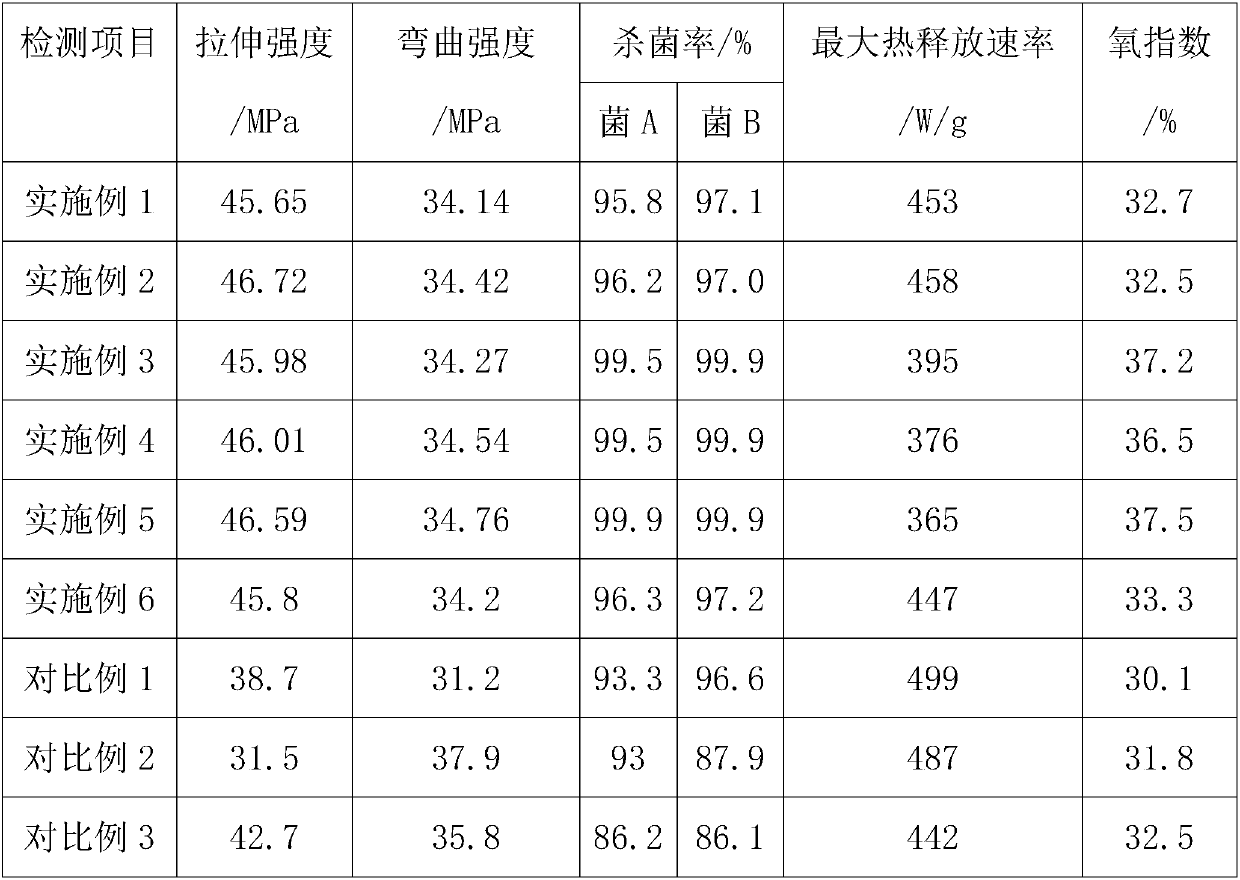

Examples

Embodiment 1

[0017] A kind of antibacterial flame-retardant polypropylene composite material that the present invention proposes, its raw material comprises by weight: 70 parts of polypropylene, 5 parts of nitrile rubber, 15 parts of butadiene rubber, 4 parts of nylon, 9 parts of ethylene octene copolymer, 1.5 parts of compatibilizer, 11 parts of silicon dioxide, 0.5 parts of nano-titanium dioxide, 3 parts of attapulgite, 1 part of calcium sulfate whisker, 17 parts of ammonium polyphosphate, 5 parts of trihydroxyethylisocyanurate, 13 parts of pentaerythritol 3 parts, aluminum hydroxide 3 parts, nickel phosphate 4 parts, nano-carbon material 0.5 parts, basalt fiber 2 parts, lauryl betaine 0.35 parts, polyhexamethylene guanidine salt 2 parts, chlorophyll cupric acid 1 part.

Embodiment 2

[0019] A kind of antibacterial flame-retardant polypropylene composite material that the present invention proposes, its raw material comprises by weight: 55 parts of polypropylene, 12 parts of nitrile rubber, 5 parts of butadiene rubber, 13 parts of nylon, 3 parts of ethylene octene copolymer, 4 parts of compatibilizer, 5 parts of silicon dioxide, 4 parts of nano titanium dioxide, 1 part of attapulgite, 3.8 parts of calcium sulfate whiskers, 8 parts of ammonium polyphosphate, 12 parts of trihydroxyethyl isocyanurate, 5 parts of pentaerythritol 8 parts, aluminum hydroxide 8 parts, nickel phosphate 0.8 parts, nano-carbon material 1.9 parts, basalt fiber 0.5 parts, lauryl betaine 0.1 part, polyhexamethylene guanidine salt 3.6 parts, chlorophyll cupric acid 0.1 part.

Embodiment 3

[0021] A kind of antibacterial flame-retardant polypropylene composite material that the present invention proposes, its raw material comprises by weight: 67 parts of polypropylene, 7 parts of nitrile rubber, 14 parts of butadiene rubber, 5 parts of nylon, 8 parts of ethylene octene copolymer, 2.3 parts of compatibilizer, 10 parts of silicon dioxide, 1 part of nano-titanium dioxide, 2.6 parts of attapulgite, 1.6 parts of calcium sulfate whiskers, 15 parts of ammonium polyphosphate, 7 parts of trishydroxyethyl isocyanurate, 12 parts of pentaerythritol 4 parts, 4 parts of aluminum hydroxide, 3.6 parts of nickel phosphate, 0.9 parts of nano-carbon materials, 1.7 parts of basalt fiber, 0.32 parts of dodecyl betaine, 2.7 parts of polyhexamethylene guanidine salt, 0.7 parts of chlorophyll cupric acid;

[0022] Wherein, the compatibilizer is a mixture of polypropylene grafted maleic anhydride, ethylene octene copolymer grafted maleic anhydride, polypropylene grafted dibutyl maleate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com