Pinus koraiensis needle essential oil as well as extraction method and application thereof in bacteriostatic culture medium

A technology of pine needle essential oil and extraction method, which is applied in the directions of essential oil/spice, fat production, etc., to achieve the effect of increasing the number of species and reducing the rate of bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Production of Red Pine Needle Essential Oil

[0059] (1) Crush the dried pine leaves, weigh 250g, place in a 2000mL retort, add 1500ml of distilled water, and soak for 4 hours.

[0060] (2) Install the container

[0061] The installation sequence is from bottom to top, from left to right. Fix the distillation bottle in the electric heating jacket, install the distillation head, connect the condenser, adjust the receiving bottle, and check all the connections.

[0062] (3) heating distillation

[0063] The initial temperature of the electric heating mantle is set at 150°C, and after the liquid boils, it drops to 120°C, and at the same time, the water inlet is turned on. It is advisable to control the distillation speed at 2-3 drops / second. When the distillation time is 4 hours and the distillate is clear and transparent, the distillation can be stopped. Turn off the power first, then stop the water inlet, and finally disassemble the distillation device, the order of ...

Embodiment 2

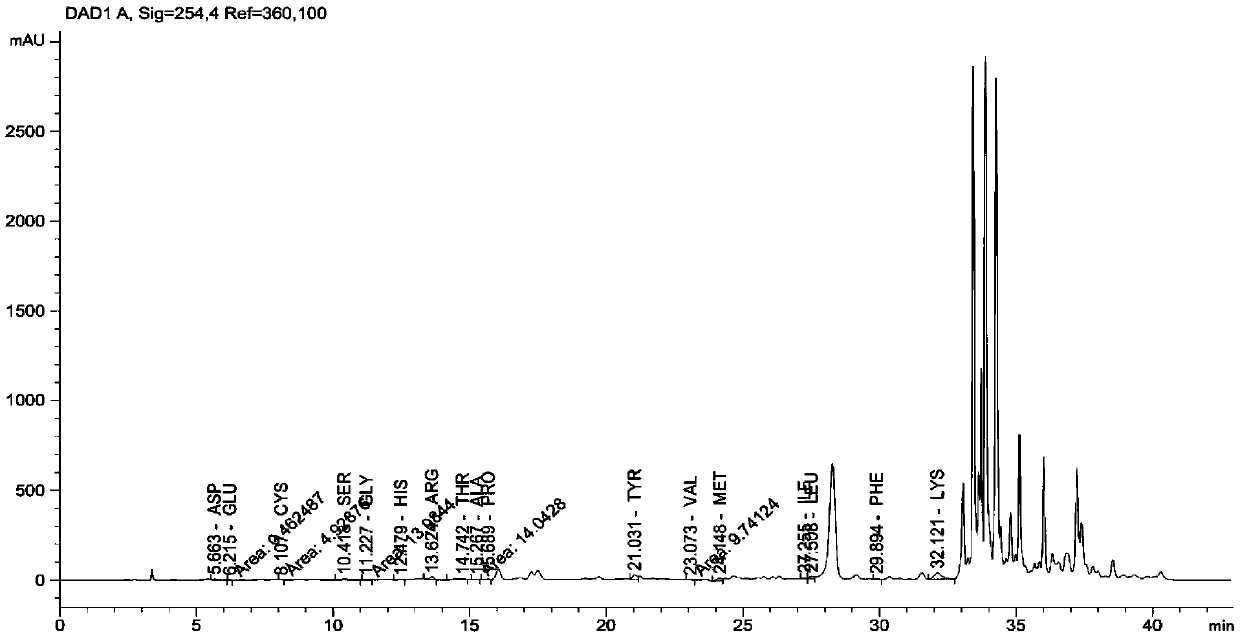

[0067] Analysis of Free Amino Acid Components by High Performance Liquid Chromatography

[0068] Analytical instrument: Shimadzu LC-20A high performance liquid chromatograph. Chromatographic conditions: mobile phase A: a mixture obtained by mixing acetonitrile and 0.1mol / L sodium acetate solution (take 8.2g of anhydrous sodium acetate and add 900ml of water to dissolve) according to the volume ratio of 3:97, adjust the pH value to 6.5 with acetic acid . Mobile phase B: a mixture obtained by mixing acetonitrile and water at a volume ratio of 4:1. Chromatographic column: AglientC18 (4.6×250mm×5μm), flow rate is 1.0ml / min, column temperature is 40°C, detection wavelength is 254nm, injection volume is 10μL, elution gradient is shown in Table 1.

[0069] Table 1 The eluting gradient table of mobile phase

[0070]

[0071] The standard chromatograms of 17 kinds of amino acids for the detection of free amino acids by high performance liquid chromatography are shown in figure 1...

Embodiment 3

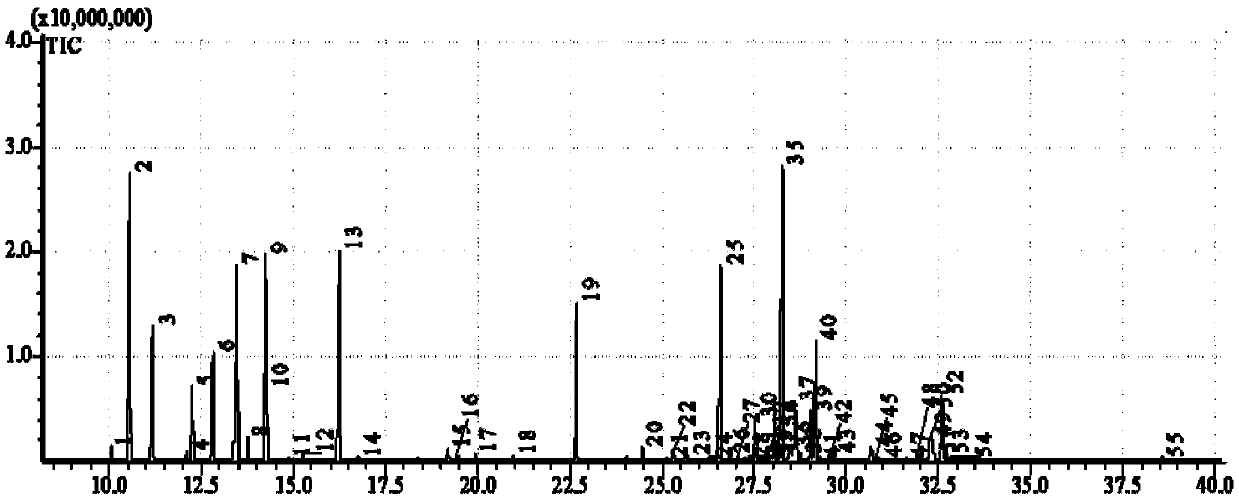

[0077] Gas chromatography-mass spectrometry analysis of volatile oil components

[0078] Analytical instrument: Shimadzu gas-mass spectrometer, GCMS-QP2010, automatic sampler: AOC-20i.

[0079] Chromatographic conditions: quartz capillary column, length 30.0cm, diameter 250.00μm, thickness 0.25μm. The linear velocity was 43.4cm / s, the flow rate was 1.44mL / min, and the heating program: the initial temperature was 40°C, kept for 5min, and then raised to 260°C at 5°C / min. Finally, run at 280°C for 7 minutes, the carrier gas is He, the temperature of the injection port is 280°C, the split ratio is 20:1, and the injection volume is 1.0 μL.

[0080] Mass spectrometry conditions: standard electron EI source (70e V), ion source temperature 230°C, interface temperature 250°C, solvent delay 3min, detection voltage 0.1KV, start time 3.00min, end time 60.00min, full scan mode, scan interval 0.30s, scanning speed is 1428, scanning range: m / z50.00-450.00.

[0081] According to the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com