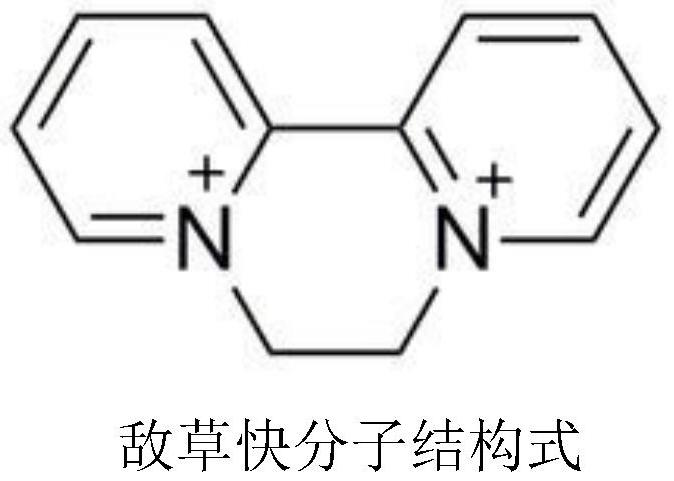

Preparation method and application of diquat molecularly imprinted polymer microspheres

A technology of molecular imprinting and diquat, applied in the directions of alkali metal compounds, chemical instruments and methods, analytical materials, etc., can solve the problems of limited enrichment multiples, complex systems, and reduced polarity, etc., and achieve strong molecular recognition ability, particle size The effect of uniform size and improved adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

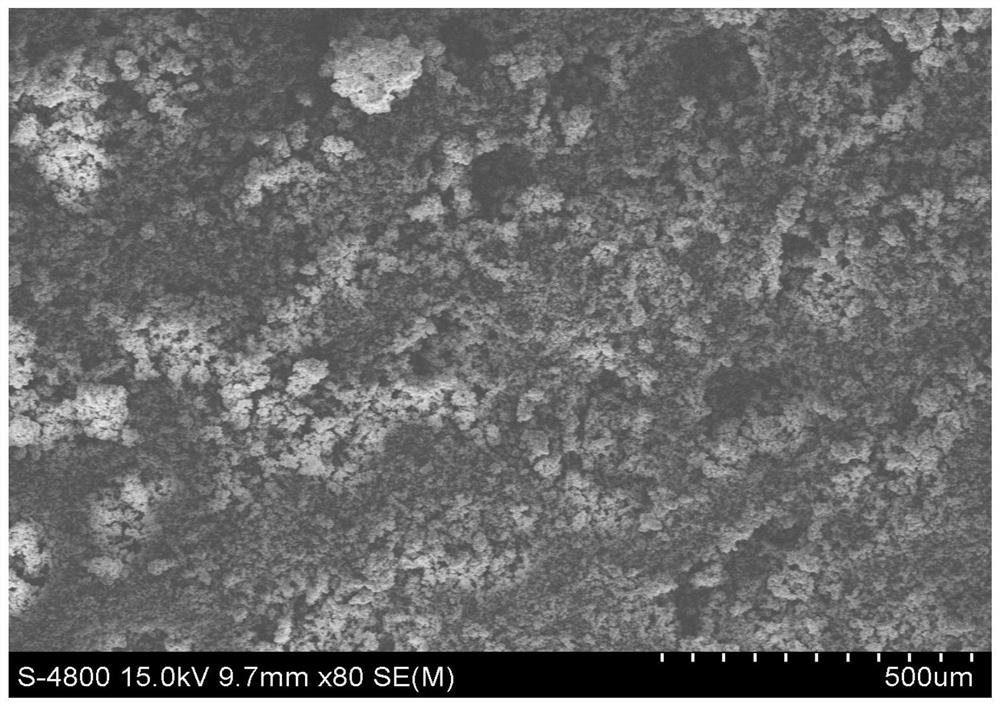

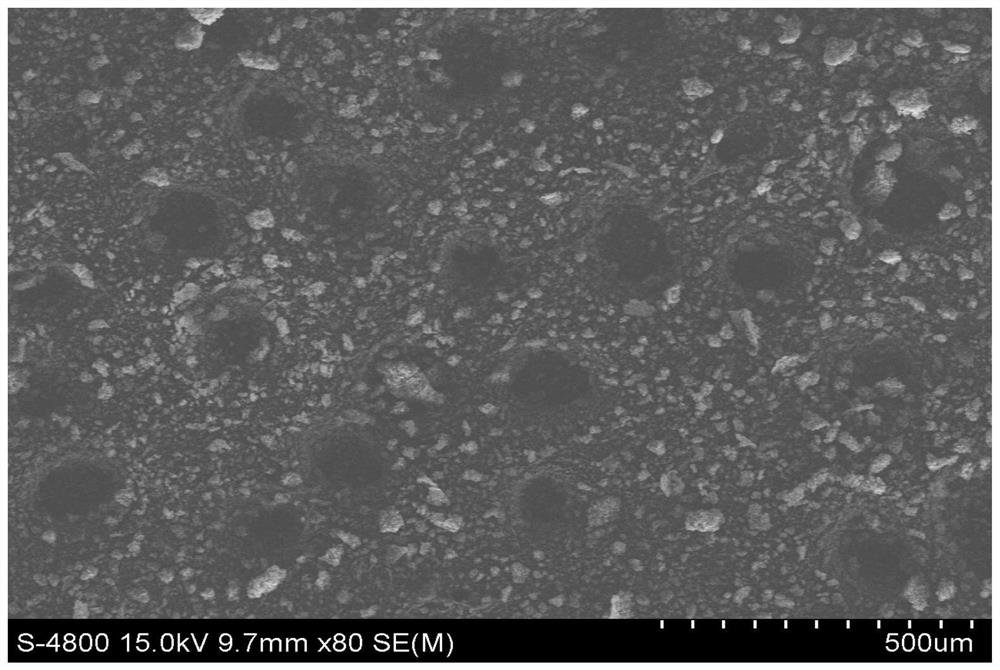

[0036] This example provides a method for preparing diquat molecularly imprinted polymer microspheres, which at least includes the following steps:

[0037] The first step, α-methacrylic acid (MAA):methyl methacrylate (MMA)=3:1, diquat is dissolved in solvent acetonitrile according to the molar ratio of 7:1, wherein, the substance of diquat The volume ratio of the amount of the solvent to the solvent is 1mmol:75mL, then add the cross-linking agent ethylene glycol dimethacrylate, the molar ratio of the cross-linking agent to diquat is 50:1, and then ultrasonically 5min, filled with nitrogen to remove oxygen, sealed, prepolymerized at 0-4°C for 15h, then transferred the prepolymer to a polypropylene plastic column polymerization reactor, added column chromatography silica gel and initiator, and α-formazol Acrylic acid (MAA): methyl methacrylate (MMA)=3:1 and the mass ratio of the mass ratio of the mass ratio of initiator azobisisobutyronitrile to methyl methacrylate (MMA)=3:1 an...

Embodiment 2

[0042] This example provides a method for preparing diquat molecularly imprinted polymer microspheres, which at least includes the following steps:

[0043] In the first step, α-methacrylic acid (MAA):methyl methacrylate (MMA)=3:1 and diquat are dissolved in the solvent acetonitrile according to the molar ratio of 9:1, wherein the diquat The volume ratio of the amount of the substance to the solvent is 1mmol:70mL, then add the cross-linking agent ethylene glycol dimethacrylate, the molar ratio of the cross-linking agent to diquat is 55:1, and then under the condition that the power is 70W Ultrasound for 3 minutes, filled with nitrogen to remove oxygen, sealed, pre-polymerized at 0-4°C for 14 hours, then transferred the prepolymer to a polypropylene plastic column polymerization reactor, added column chromatography silica gel and initiator, α-formazol The mass ratio of the sum of the amount of substances of base acrylic acid and crosslinking agent to initiator azobisisobutyroni...

Embodiment 3

[0047] This example provides a method for preparing diquat molecularly imprinted polymer microspheres, which at least includes the following steps:

[0048] In the first step, α-methacrylic acid (MAA):methyl methacrylate (MMA)=3:1 and diquat are dissolved in the solvent acetonitrile according to the molar ratio of 6:1, wherein the diquat The volume ratio of the amount of the substance to the solvent is 1mmol:90mL, then add the cross-linking agent ethylene glycol dimethacrylate, the molar ratio of the cross-linking agent to diquat is 58:1, and then under the condition that the power is 75W Ultrasound for 4 minutes, filled with nitrogen to remove oxygen, sealed, pre-polymerized at 0-4°C for 10 hours, then transferred the prepolymer to a polypropylene plastic column polymerization reactor, added column chromatography silica gel and initiator, and α- Methacrylic acid (MAA): methyl methacrylate (MMA)=3:1 and the mass ratio of the mass ratio of initiator azobisisobutyronitrile and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com