A kind of solid phase microextraction coating preparation method

An extraction and coating technology, applied in the field of solid-phase microextraction coating preparation, can solve the problems of large environmental pollution, low mechanical strength, and poor thermal stability in the preparation process, and achieve reduced environmental pollution, high mechanical strength, and extraction of coatings. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

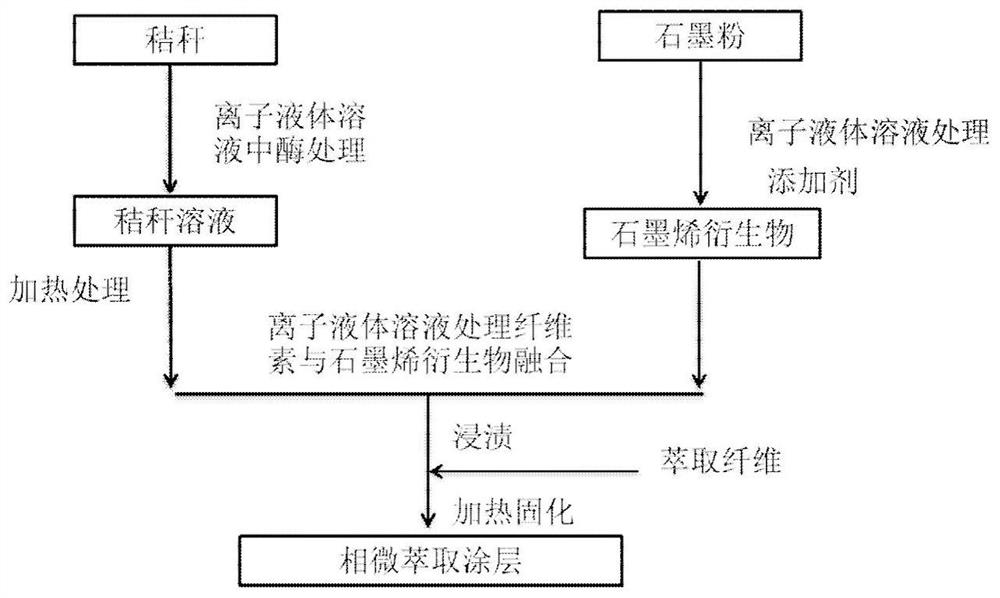

[0023] The solid-phase microextraction coating preparation method of the present embodiment comprises the steps:

[0024] (1) Preparation of straw powder: cut corn straw into small pieces of about 0.5 cm, dry, crush, and pass through a 100-mesh sieve;

[0025] (2) Preparation of ionic liquid aqueous solution: 30% (W / V%) ionic liquid aqueous solution: take 30g ionic liquid 1-ethyl-3-methylimidazole diethyl phosphate salt, add 100ml deionized water;

[0026] (3) Preparation of straw solution: take 100g of 30% ionic liquid aqueous solution, add 1g of straw, add 0.01g of cellulase and pectinase, stir at 50°C for 30min, filter to obtain straw, dry, add 80% 1-ethyl- 100 g of a mixed solution of 3-methylimidazolium phosphate diethyl ester salt and 20% DMSO was heated at 150° C. for 1 hour, and cooled for later use to obtain a straw solution;

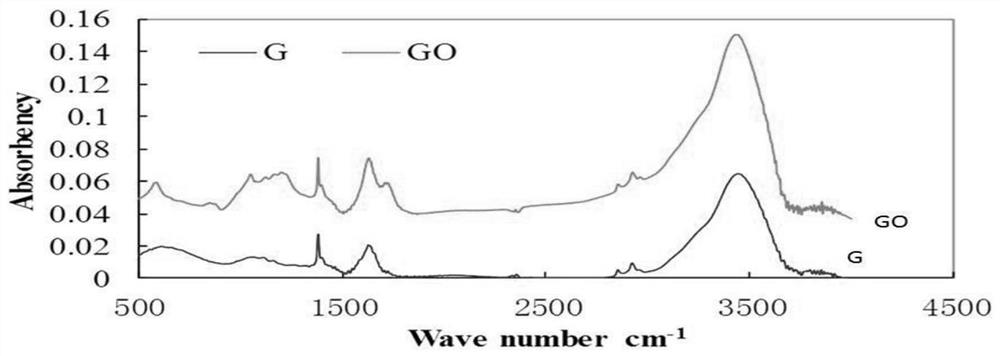

[0027] (4) Preparation of graphene oxide derivatives: Add 1g of graphite powder to 100g of acidic ionic liquid 1-ethyl-3-methylimidazole diet...

Embodiment 2

[0032] The solid-phase microextraction coating preparation method of the present embodiment comprises the steps:

[0033] (1) Preparation of straw powder: cut mulberry straw into small pieces of about 0.5 cm, dry, crush, and pass through a 100-mesh sieve;

[0034] (2) Preparation of ionic liquid aqueous solution: 30% (W / V%) ionic liquid aqueous solution: take 30g ionic liquid 1-butyl-3-methylimidazolium chloride salt, add 100ml deionized water;

[0035] (3) Preparation of straw solution: Take 100g of 30% ionic liquid aqueous solution, add 1g of straw, add 0.01g of cellulase, stir at 50°C for 30min, filter to obtain straw, dry, add 90% 1-ethyl-3-methylimidazole 100 g of a mixed solution of diethyl phosphate salt and 10% DMSO was heated at 160° C. for 30 min, and cooled for later use to obtain a straw solution;

[0036] (4) Preparation of graphene oxide derivatives: Add 1g of graphite powder to 100g of acidic ionic liquid 1-ethyl-3-methylimidazole diethyl phosphate salt, add it t...

Embodiment 3

[0041] The solid-phase microextraction coating preparation method of the present embodiment comprises the steps:

[0042] (1) Preparation of straw powder: cut wheat straw into small pieces of about 0.5 cm, dry, crush, and pass through a 100-mesh sieve;

[0043] (2) Preparation of ionic liquid aqueous solution: 30% (W / V%) ionic liquid aqueous solution: get 30g 1-ethyl-3-methylimidazole phosphate dimethyl salt and 1-butyl-3-methylimidazole acetic acid Add 100ml of deionized water to the ionic liquid in which the salt is mixed according to 1:1 (W / W);

[0044] (3) Preparation of straw solution: Take 100g of 30% ionic liquid aqueous solution, add 1g of straw, add 0.01g of pectinase, stir at 50°C for 30min, filter to obtain straw, dry, add 85% 1-ethyl-3-methylimidazole 100 g of a mixed solution of dimethyl phosphate salt and 15% DMSO was heated at 160° C. for 30 min, and cooled for later use to obtain a straw solution;

[0045] (4) Preparation of graphene oxide derivatives: Add 1g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com