Preparation method of fullerene thin film for organic solar cell

A technology of solar cells and fullerenes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low conversion efficiency and high price, achieve the effects of reducing the content of impurities, mild preparation method conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

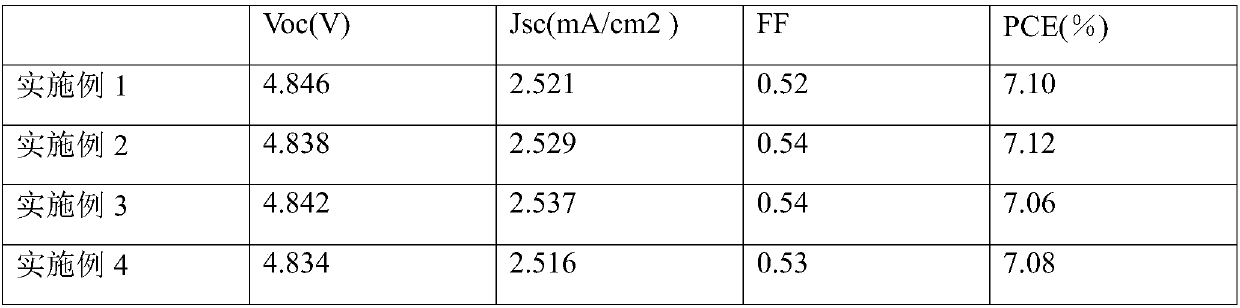

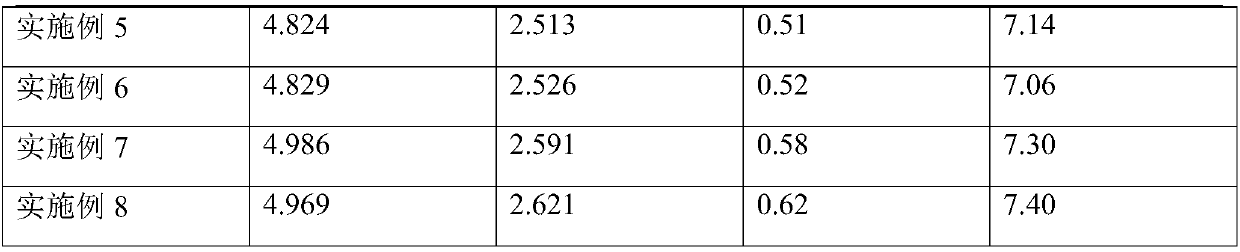

Examples

Embodiment 1

[0034] A method for preparing a fullerene film for an organic solar cell, comprising the steps of:

[0035]Step 1. Dissolve salicylic acid in deionized water to form a 2.0mol / L salicylic acid aqueous solution, add aniline under the protection of an inert protective gas, shake on a shaker for at least 20 minutes to mix evenly, and then add 5.0mol / L L of ammonium persulfate aqueous solution, placed on a shaker for at least 30 minutes to mix evenly, left to stand for at least 24 hours, centrifuged to remove the supernatant, purified water to wash the solid for at least 2 times, put the solid in an oven to dry, and then pulverize to obtain Powder A; the volume ratio of the salicylic acid aqueous solution, aniline and ammonium persulfate aqueous solution is 1:0.7:1.2 in turn; the shaking temperature of the shaker is 40°C, and the speed of the shaker is 200r / min; The drying temperature is 80°C, and the drying time is ≥1 hour; the particle size of the powder A is ≥100 mesh;

[0036]...

Embodiment 2

[0040] A method for preparing a fullerene film for an organic solar cell, comprising the steps of:

[0041] Step 1. Dissolve salicylic acid in deionized water to form a 3.0mol / L salicylic acid aqueous solution, add aniline under the protection of an inert protective gas, shake on a shaker for at least 20 minutes to mix evenly, and then add 6.0mol / L L of ammonium persulfate aqueous solution, placed on a shaker for at least 30 minutes to mix evenly, left to stand for at least 24 hours, centrifuged to remove the supernatant, purified water to wash the solid for at least 2 times, put the solid in an oven to dry, and then pulverize to obtain Powder A; the volume ratio of the salicylic acid aqueous solution, aniline and ammonium persulfate aqueous solution is 1:0.9:1.2 in sequence; the shaking temperature of the shaking table is 50°C, and the speed of the shaking table is 300r / min; The drying temperature is 100°C, and the drying time is ≥1 hour; the particle size of the powder A is ...

Embodiment 3

[0046] A method for preparing a fullerene film for an organic solar cell, comprising the steps of:

[0047] Step 1. Dissolve salicylic acid in deionized water to form a 2.5mol / L salicylic acid aqueous solution, add aniline under the protection of an inert protective gas, shake it on a shaker for at least 20 minutes to mix evenly, and then add 5.5mol / L L of ammonium persulfate aqueous solution, placed on a shaker for at least 30 minutes to mix evenly, left to stand for at least 24 hours, centrifuged to remove the supernatant, purified water to wash the solid for at least 2 times, put the solid in an oven to dry, and then pulverize to obtain Powder A; the volume ratio of the salicylic acid aqueous solution, aniline and ammonium persulfate aqueous solution is 1:0.8:1.4 in turn; the shaking temperature of the shaker is 45°C, and the speed of the shaker is 250r / min; The drying temperature is 90°C, and the drying time is ≥1 hour; the particle size of the powder A is ≥100 mesh;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com