Preparation method of hydrogel film with high adhesion to skin and function of promoting wound healing

A technology for wound healing and hydrogel film, which can be used in skin diseases, medical preparations with non-active ingredients, non-active ingredients of polymer compounds, etc. It can solve the problems of poor skin fit and poor film-forming performance, and achieve excellent Adhesion, excellent biocompatibility, effect on reducing trauma scars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Synthesis of mono-6-deoxy-p-toluenesulfonyl chloride cyclodextrin (β-CD-6-OTs):

[0030] Dissolve β-cyclodextrin (β-CD) (17.0g, 15.0mmol) in 200mL of 1% NaOH solution, and add 15mL of p-toluenesulfonyl chloride (4.0g, 22.5mmol) dropwise at 0°C ) in acetonitrile solution, stirred and reacted at 25°C for 2h, then filtered, adjusted to pH 2 with hydrochloric acid, kept at 4°C overnight, a large amount of precipitates precipitated, filtered, and the solid was recrystallized 3 times to obtain a white solid, dried in vacuo at 40°C for 5h, to obtain Mono 6-p-toluenesulfonyl cyclodextrin, spare.

[0031] (2) Synthesis of mono-6-deoxy-dopamine cyclodextrin (β-CD-6-DA):

[0032] Take 1.00g (0.78mmol) of mono-6-p-toluenesulfonyl cyclodextrin, 0.80g (4.22mmol) of dopamine hydrochloride, add catalyst DMAP to 0.19g (1.5mmol), KI to 0.06g (0.4mmol), and repeatedly vacuumize And fill with nitrogen, then inject 10mL of anhydrous DMF and 1mL of anhydrous methanol into the needle, d...

Embodiment 2

[0036] According to the reaction method of Example 1, the molecular weight of hyaluronic acid was changed to study the influence of molecular weight on the mechanical strength of the hydraulic membrane. When the molecular weight of hyaluronic acid varies from 400kDa to 1300kDa, its influence on the stress-strain value of the hydrogel membrane is verified.

[0037] Table 4 Effect of crosslinking agent content on hydrogel film stress-strain value

[0038] Molecular weight (kDa)

[0039] It can be seen from Table 4 that the molecular weight of hyaluronic acid has an optimal range. To prepare a hydrogel film similar to the elasticity and toughness of the skin epidermis, an appropriate molecular weight must be provided. When the molecular weight of hyaluronic acid is too small, the crosslinking strength is not enough. , causing the stress and strain of the gel film to be small, which cannot match the elastic strain value of the skin. Therefore, it can be known from experi...

Embodiment 3

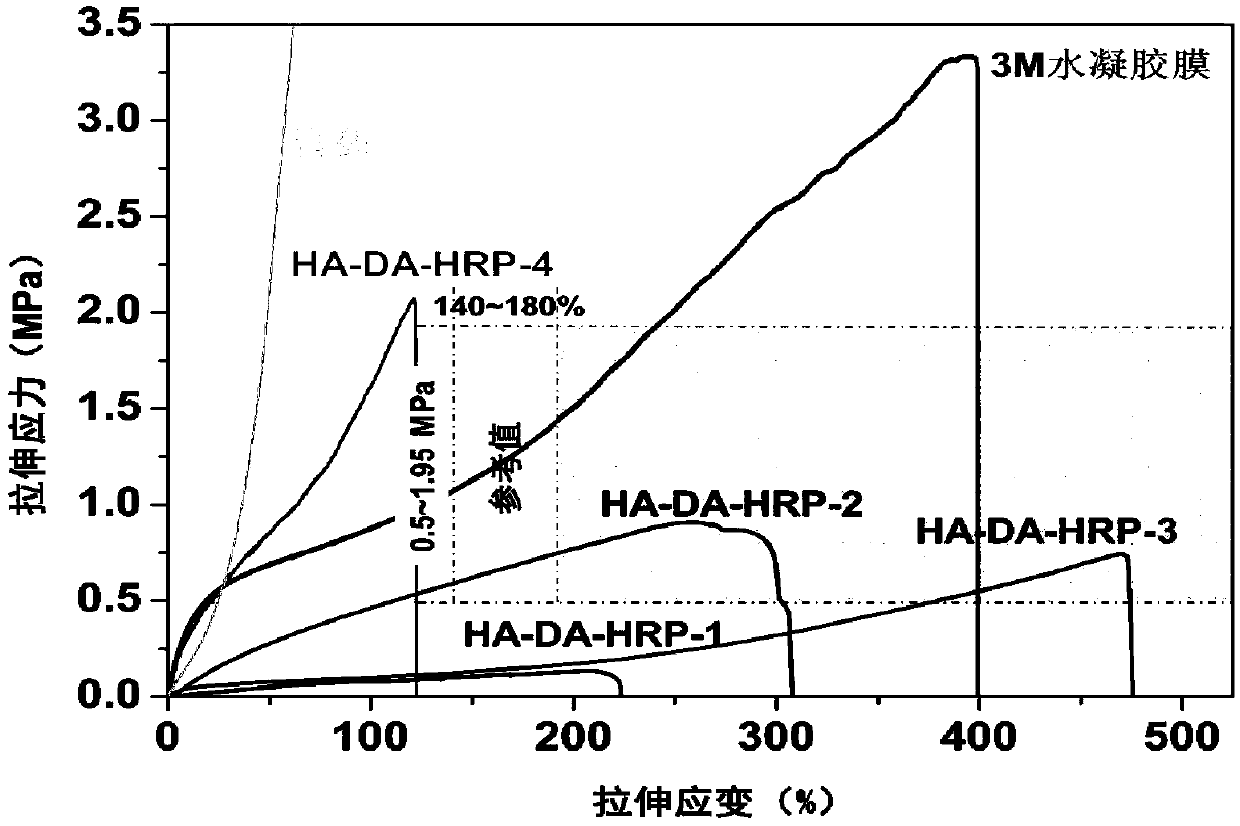

[0041] According to the reaction method of Example 1, change the molar ratio of HA and β-CD-6-DA reaction substrate, when the reaction molar ratio of HA and β-CD-6-DA is respectively 1:1, 2:1, 4 :1 and 8:1, the hydrogel films prepared were denoted as HA-DA-HRP-1, HA-DA-HRP-2, HA-DA-HRP-3, and HA-DA-HRP-4, respectively. Then use a universal testing machine to test the tensile elongation at break of the four film materials, commercial 3M hydrogel and wound plaster. Test results such as figure 1 shown.

[0042] Depend on figure 1 The results show that HA-DA-HRP-2 and HA-DA-HRP-3 are greater than the elongation at break (140-180%) of human skin stretching, but the tensile stress at break is in the range of 0.50-1.85MPa, indicating that The films prepared by HA-DA-HRP-2 and HA-DA-HRP-3 have the same tensile strength as the skin epidermis, that is, HA-DA-HRP-2 and HA-DA-HRP-3 films It has the function of skin stretch response. However, the tensile strength of commercial 3M hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com