Micro-nano composite particles and liquid phase insertion preparation process thereof

A technology of micro-nano composite and preparation process, which is applied in the direction of aluminum compounds, nanotechnology, nanotechnology, etc., and can solve the problems of small amount of filler and inability to play its role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

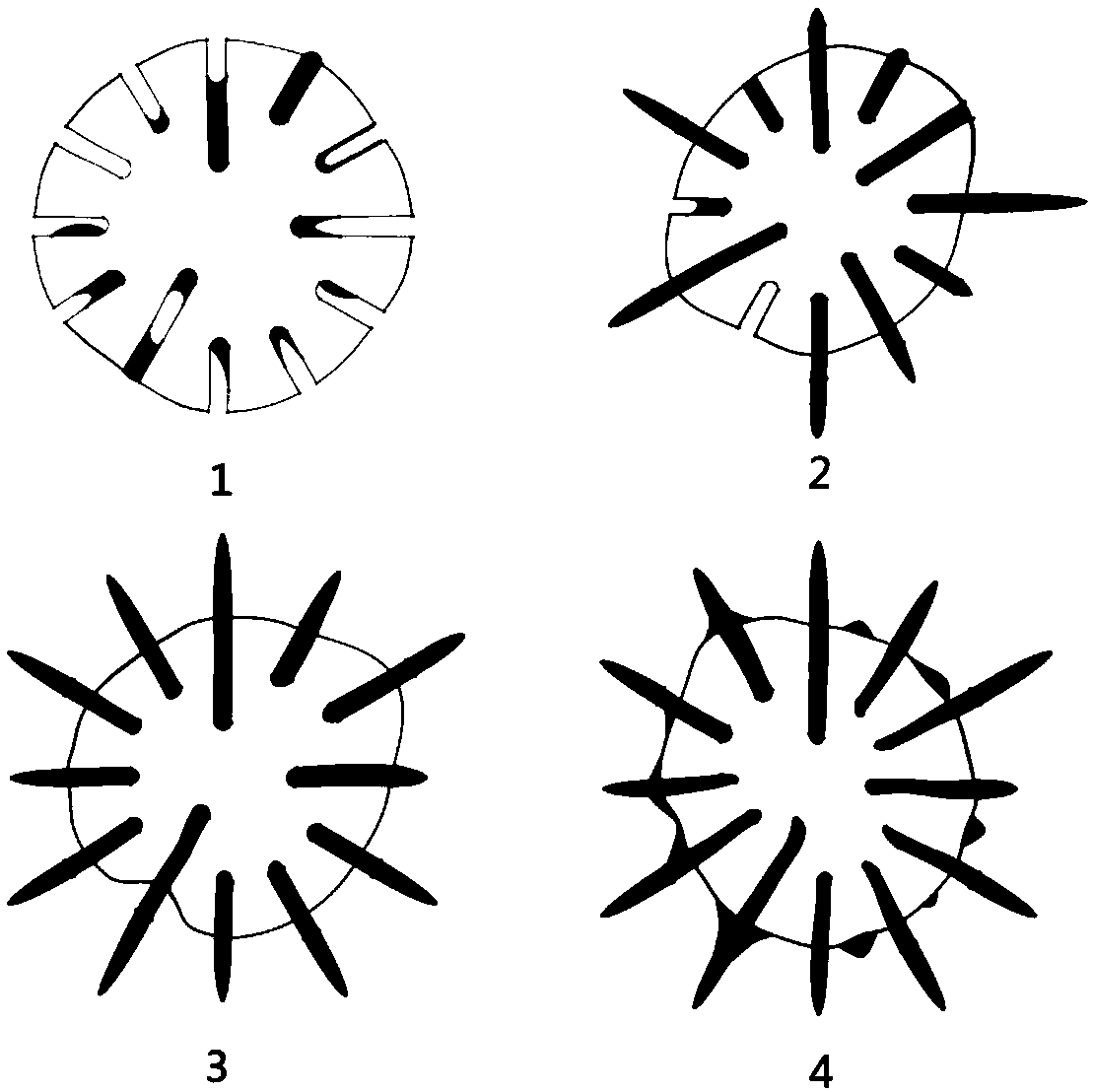

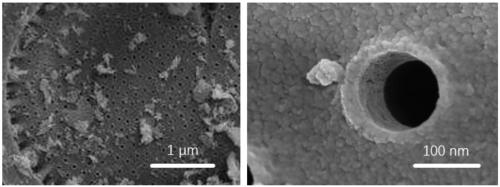

[0071] In a micro-nano composite particle provided in this embodiment, nano-scale particles smaller than the micro-pore diameter of the porous micro-nano particle and below the nano-scale are inserted into the porous micro-nano particle to form a three-dimensional porous and / or thorn-shaped micro-nano composite particle. The single pore embedded amount of porous and / or thorn-like micro-nano composite particles is 5-100% of the pore volume, and the BET nitrogen adsorption specific surface area is 30m 2 / g~350m 2 / g, see figure 1 As shown in the figure, the state of the micro-nano composite particles is that the nano-scale and below-nano-scale particles may not be inserted or partially inserted or fully inserted and formed into thorns, and even a certain degree of nano-scale and below-nanoscale particles are attached to the surface of the substrate. figure 2The 10000x and 100000x scanning electron microscope photos of the three-dimensional porous / thorn-like micro-nano composit...

Embodiment 2

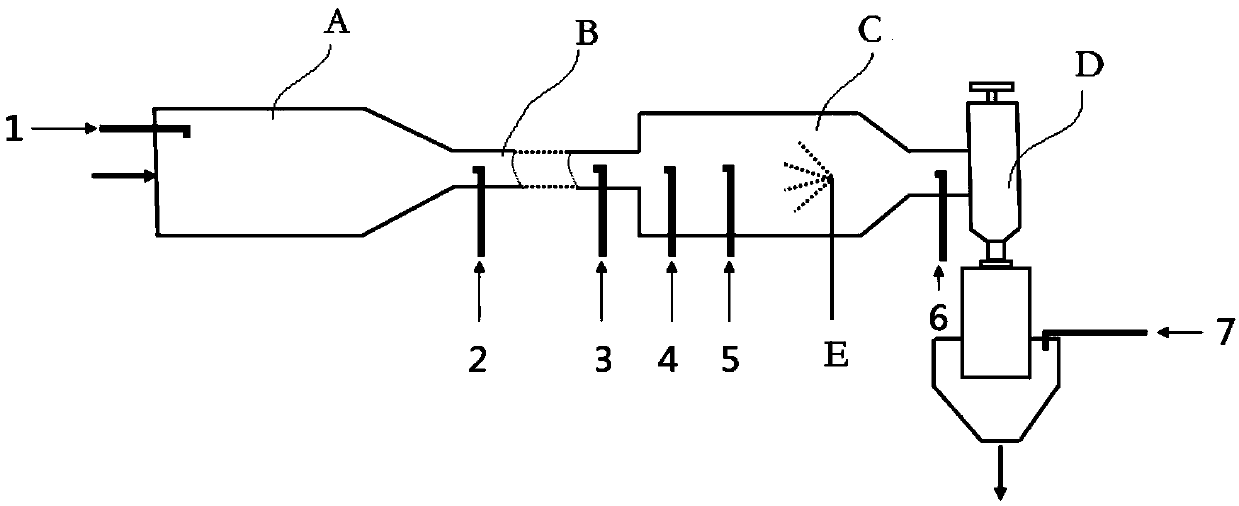

[0076] The present embodiment provides a preparation process of the above-mentioned micro-nano composite particles, comprising the following steps:

[0077] S1. get zinc nitrate hexahydrate and dissolve it in deionized water to form a zinc nitrate solution of 10 g / ml, and stir for 2 minutes for subsequent use;

[0078] S2. Mix silica and aluminum oxide porous micro-nano composite substrate with methanol to obtain a solution of porous micro-nano particles, and place it in an ultrasonic instrument for ultrasonic dispersion. The ultrasonic frequency is 60 Hz, the temperature is below 50 °C, and the ultrasonic time is For 0.1h, a porous micro-nano particle suspension with a concentration of 20g / ml is obtained; in this embodiment, the composite substrate is made of 20% silicon dioxide and 80% aluminum oxide in parts by weight;

[0079] S3. Dissolve ammonia water in deionized water and configure it into 30% concentration of ammonia water for use;

[0080] S4. Mix the porous micro-n...

Embodiment 3

[0086] The present embodiment provides a preparation process of the above-mentioned micro-nano composite particles, comprising the following steps:

[0087] S1. get copper sulfate and dissolve it in deionized water to form a copper sulfate solution of 20g / ml, stir for 2 minutes and then use it for later use;

[0088] S2. Mix calcium carbonate and aluminum oxide porous micro-nano composite substrate with ethanol to obtain a solution of porous micro-nano particles, and place it in an ultrasonic device for ultrasonic dispersion. The ultrasonic frequency is 30 Hz, the temperature is below 80 °C, and the ultrasonic time is 2h, a porous micro-nano particle suspension with a concentration of 1 g / ml was obtained; in this embodiment, the composite substrate was prepared with 95% calcium carbonate and 5% aluminum oxide in parts by weight;

[0089] S3. Dissolve urea in deionized water, and configure it as a buffer solution with a concentration of 50% for later use (ammonium root and copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com