A kind of preparation method of nano-gold particles with different particle sizes

A technology of nano-gold particles and particle size, which is applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems that the shape and size are difficult to control, the particle size parameters of nanoparticles cannot be adjusted, and the process parameters are difficult to control. Achieve the effects of adjustable particle size parameters, easy adjustment of preparation process parameters, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

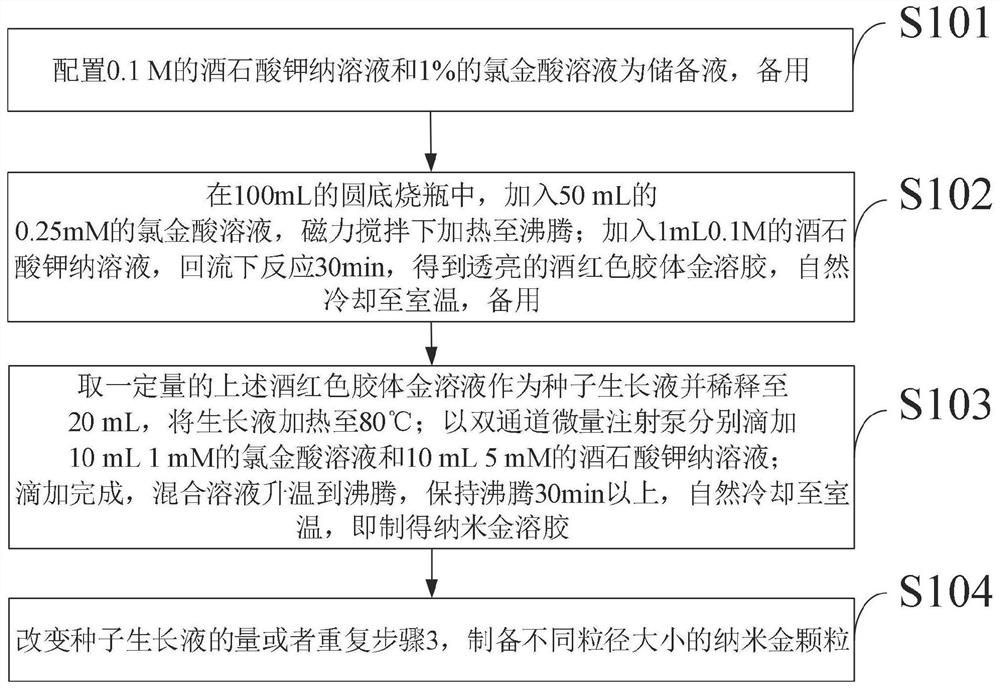

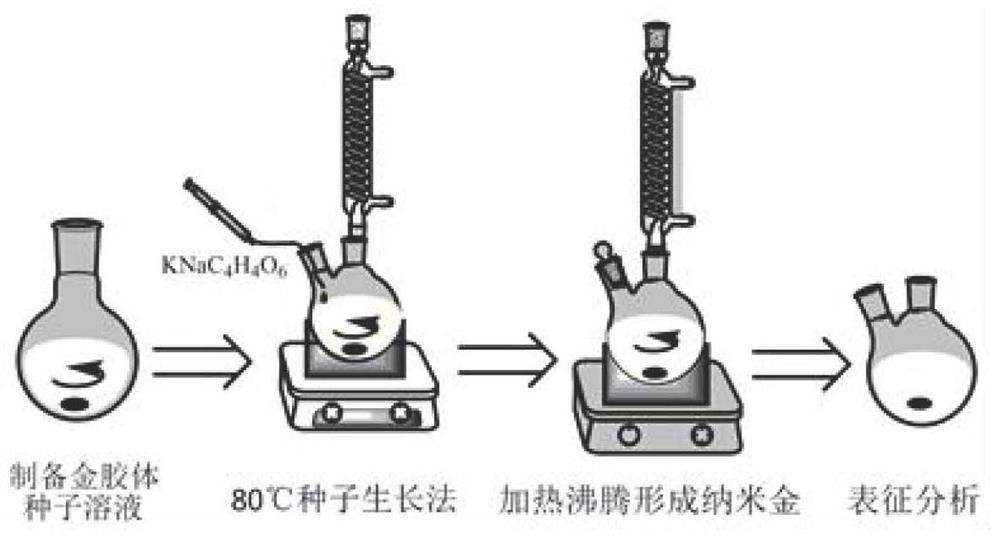

[0029] Below in conjunction with accompanying drawing, preparation method of the present invention is further described;

[0030] Such as figure 1 As shown, the preparation method of gold nanoparticles with different particle sizes provided by the embodiments of the present invention:

[0031] S101: Prepare 0.1M sodium potassium tartrate solution and 1% chloroauric acid solution as stock solution, and set aside;

[0032] S102: In a 100mL round-bottomed flask, add 50mL of 0.25mM chloroauric acid solution, and heat to boiling under magnetic stirring; add 1mL of 0.1M sodium potassium tartrate solution, and react under reflux for 30min to obtain translucent wine red colloidal gold Sol, naturally cooled to room temperature, set aside;

[0033] S103: Take a certain amount of the above-mentioned wine red colloidal gold solution as the seed growth solution and dilute it to 20mL, heat the growth solution to 80°C; add 10mL of 1mM chloroauric acid solution and 10mL of 5mM tartaric acid...

Embodiment 1

[0042] (1) configure 0.1M sodium potassium tartrate solution and 1% chloroauric acid solution for subsequent use;

[0043] (2) In a 100 mL round bottom flask, dilute 515 μL of 1% chloroauric acid stock solution to 50 mL to obtain a 0.25 mM chloroauric acid solution, and heat to boiling with magnetic stirring. Then quickly add 1mL of 0.1M sodium potassium tartrate solution, and react under reflux for 30min to obtain a bright wine red colloidal gold sol, which is naturally cooled to room temperature for later use.

[0044](3) Take an appropriate amount of the above nano-gold sol for ultraviolet-visible spectroscopy (UV-Vis) analysis and transmission electron microscope (TEM) analysis.

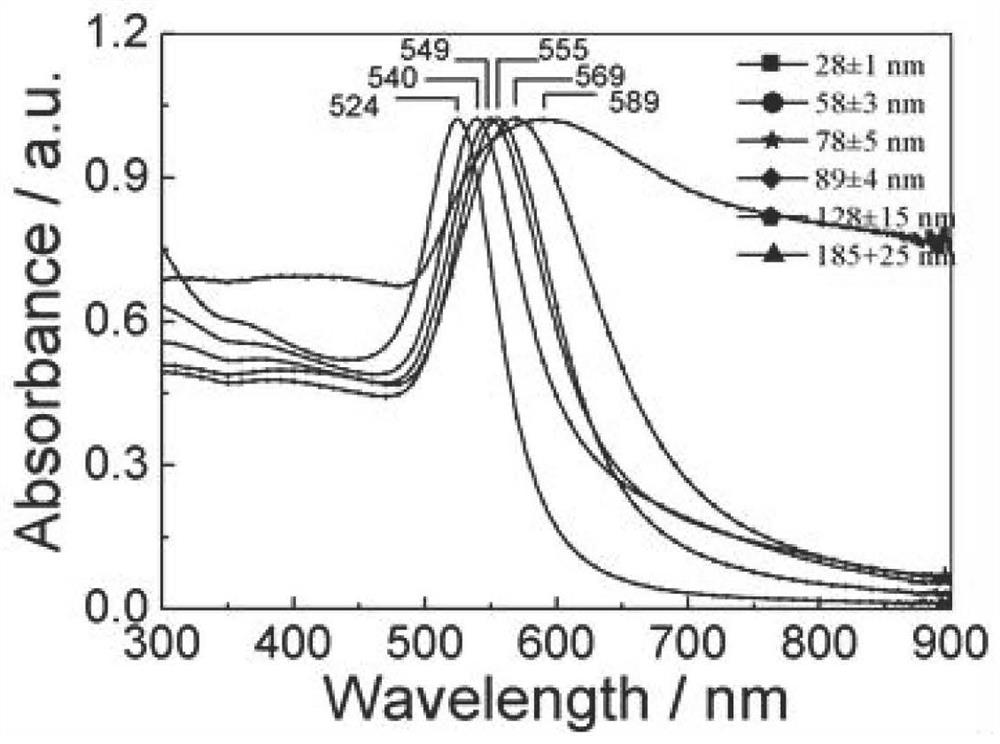

[0045] Such as image 3 and Figure 4 As shown in A, the maximum absorption peak of the nano-gold sol is located at 524nm, and through TEM analysis, it can be known that its particle size is 28±1nm, and the particles present good monodispersity.

[0046] (4) Take appropriate amount of above-me...

Embodiment 2

[0049] (1) configure 0.1M sodium potassium tartrate solution and 1% chloroauric acid solution for subsequent use;

[0050] (2) In a 100 mL round bottom flask, dilute 515 μL of 1% chloroauric acid stock solution to 50 mL to obtain a 0.25 mM chloroauric acid solution, and heat to boiling with magnetic stirring. Then quickly add 1mL of 0.1M sodium potassium tartrate solution, and react under reflux for 30min to obtain a bright wine red colloidal gold sol, which is naturally cooled to room temperature for later use.

[0051] (3) Take 4mL of the above colloidal gold sol as the seed growth solution and dilute it to 20mL, and heat the growth solution to 80°C, then add 10mL of 1mM chloroauric acid solution and 10mL of 5mM potassium tartrate sodium solution (dropping method is simple constant speed mode and the speed is 20mL / h). After the dropwise addition is completed, the mixed solution is heated to boiling, kept boiling for 30 minutes, and then naturally cooled to room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com