Phthalic acid ester plastifier single-stranded DNA nucleic acid aptamer and screening and representing method and electrochemical sensor thereof

A technology of monobutyl phthalate and nucleic acid aptamer, which is applied in the biological field, can solve the problems of no specific recognition of phthalate plasticizer nucleic acid aptamers reported, and achieve high affinity And selectivity, high affinity, good specificity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

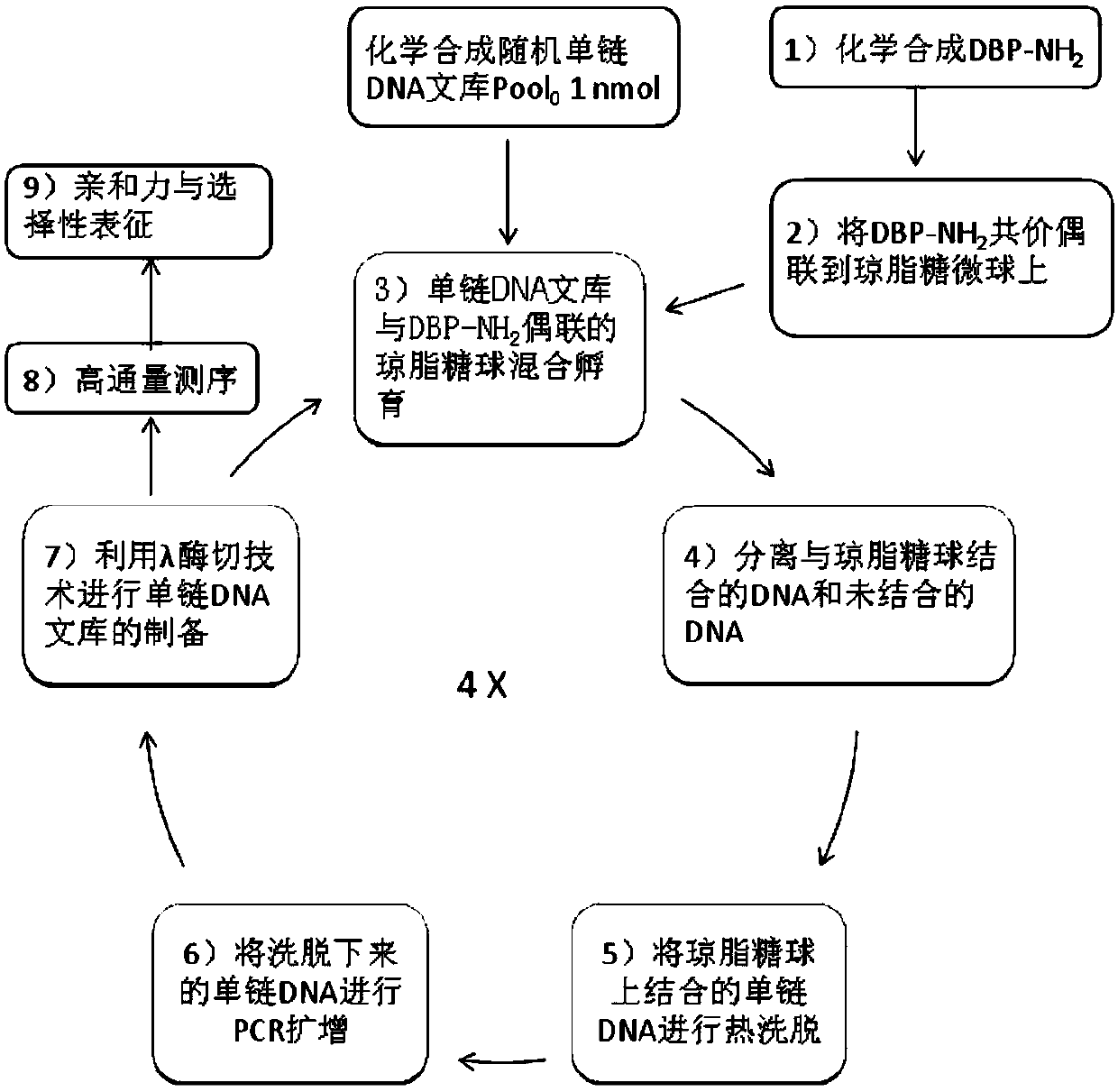

[0035] Example 1: Technical route for screening single-stranded DNA aptamers of phthalate plasticizers using SELEX and high-throughput sequencing technology

[0036] Such as figure 1 As shown, the technical route of the present invention for screening single-stranded DNA nucleic acid aptamers of phthalate plasticizers using SELEX and high-throughput sequencing technology includes the following steps: (1) DBP-NH 2 Chemical synthesis and characterization; (2) DBP-NH 2 Epoxy-activated Sepharose microspheres (Epoxy-activated Sepharose TM 6B) coupling and characterization; (3) 6×10 14 (1nmol) of commercially synthesized starting single-stranded DNA library (pool 0 , Table 1) and DBP-NH 2 The coupled agarose microspheres are mixed and incubated; (4) the agarose microspheres bound with the nucleic acid aptamer are separated and washed from the DNA sequence not bound to the agarose microspheres; (5) the washed agarose The nucleic acid aptamers on the microspheres were eluted by heat; (6)...

Embodiment 2

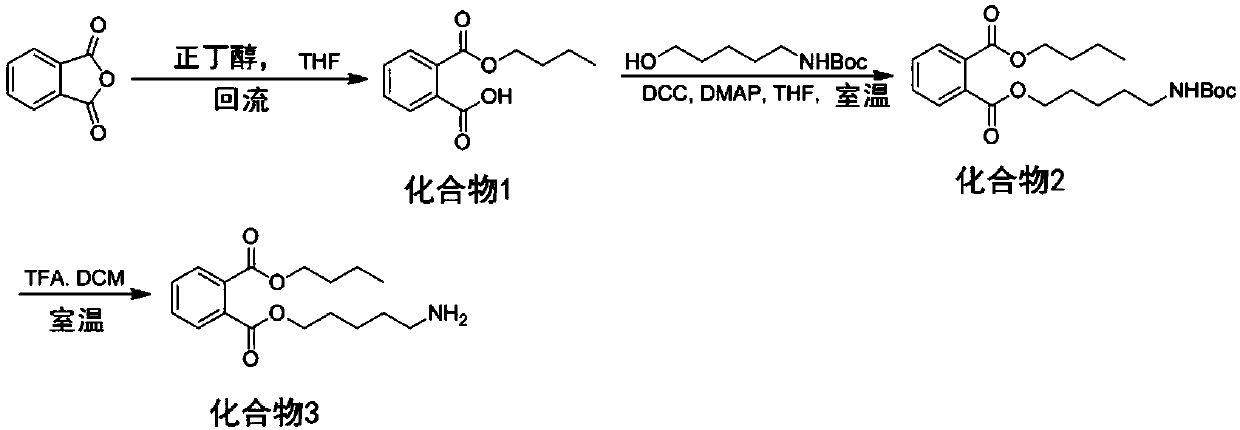

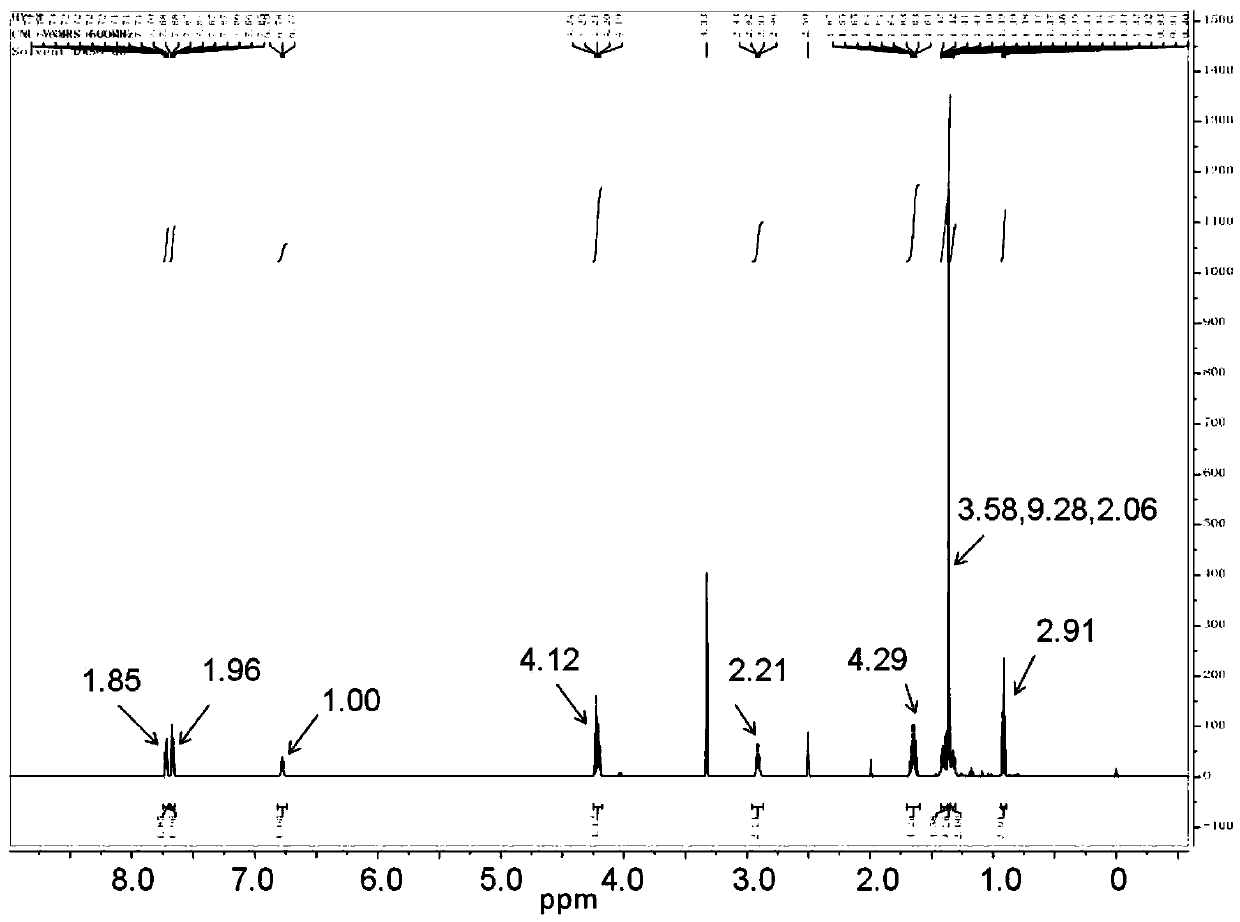

[0037] Example 2: The amino derivative of DBP (DBP-NH 2 ) Synthesis and characterization

[0038] DBP-NH 2 The synthetic route is as figure 2 Shown. The reagents used in this example are all analytically pure, each step of the reaction process is monitored in real time by thin layer chromatography, and the product is separated and purified by a silica gel column. The specific synthesis method, conditions and characterization are as follows (1-3):

[0039] (1) Preparation of monobutyl phthalate (compound 1)

[0040] Add n-butanol (5ml) to a 50ml dry round bottom flask containing phthalic anhydride (8.5g, 57mmol), anhydrous tetrahydrofuran (7.5ml) and clean and dry magnets. Stir magnetically Heat to reflux at 60°C for 9 hours. An insoluble white solid is formed. After standing at room temperature, filter with suction, wash the bottle with tetrahydrofuran and filter with suction again. A white paste-like substance was obtained after rotary steaming. Join CH 2 Cl 2 Afterwards, the...

Embodiment 3

[0045] Example 3: DBP-NH 2 Coupling on epoxy activated agarose microspheres

[0046] 0.1 g of epoxy-activated agarose microspheres were swollen with deionized water, and washed repeatedly with 20 mL of deionized water to obtain 350 μL wet spheres. Then use 0.2M Na 2 CO 3 (pH≈12) Wash the agarose balls. Add 46.7mg (0.15mmol) DBP-NH to the 500μL reaction system 2 , Placed at room temperature to shake for 48 hours. After the reaction, use pH 4.5 sodium acetate buffer solution (0.1M sodium acetate, 0.5M NaCl) and pH 12 sodium carbonate buffer solution (0.2M NaHCO 3 / Na 2 CO 3 , 0.5M NaCl) alternately wash the agarose microspheres three times, and finally wash with water, and dilute to 500μL, and store in a refrigerator at 4°C for later use. Elemental analysis (Elementar Vario MICROCUBE, Germany) showed that the proportions of the constituent elements C, H, N, and S of the agarose spheres were 33.61%, 9.26%, 0.92% and 1.09%, respectively. Coupling DBP-NH 2 After that, the proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com