Method for preparing swainsonine by solid fermentation

A solid fermentation method, swainsonine technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of high cost, long time, low purity, etc., to save extraction costs, easy to obtain , The effect of shortening the separation and extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1) Source of bacteria

[0076] The fungus used is derived from the endophytic fungus Alternariasect.Undifilumoxytropis of the locoweed plant, provided by the China Industrial Microbiology Culture Collection and Management Center.

[0077] 2) Strain cultivation and fermentation

[0078] PDA solid medium: 200g of potatoes, 20g of glucose and 15-20g of agar, after boiling, add distilled water to 1000mL.

[0079] Rice medium: 60g of rice, 80mL of distilled water, autoclaved at 121°C for 30 minutes and then set aside.

[0080] First, inoculate the purchased strains on PDA solid medium for activation, and store some well-grown strains in refrigerators at 4°C and -20°C respectively for subsequent needs, and the rest grow well on PDA solid medium The strains are reserved for further solid fermentation.

[0081] Secondly, the fungus growing on the PDA medium and in the logarithmic phase was cut into small pieces, inoculated on the rice medium in the ultra-clean workbench, and...

Embodiment 2

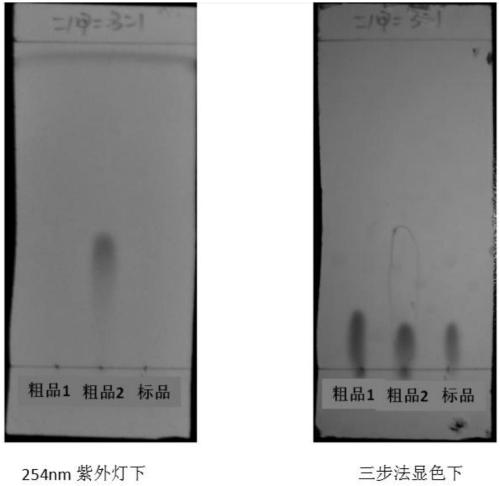

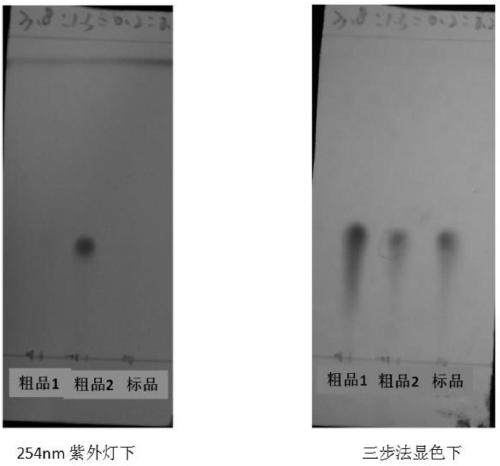

[0098] The contrast of embodiment 2 eluents

[0099] 1. TLC sample point selection: take the commercially available swainsonine standard product (purity above 99%), and the alkaline n-butanol part extract prepared according to steps 1) to 3) of Example 1 as the extract containing Crude product of swainsonine;

[0100] 2. Dissolve the swainsonine standard substance with chromatographic methanol, and be prepared with a concentration of 5mg / ml swainsonine standard solution (standard product 1); Each is prepared into a concentration of swainsonine crude product solution of 10mg / ml, which is recorded as crude product 1 and crude product 2;

[0101] 3. Choose the GF254 type of silica gel thin-layer plate, cut it into a suitable size with a glass knife, and wait for the sample to be loaded. Use clean 0.3mm capillary pipettes to absorb standard product 1, crude product 1, and crude product 2 respectively onto the prepared thin-layer plates, and prepare two thin-layer plates that hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com