Preparation method of vanadium oxide nanobelt/nickel foam composite self-supporting electrode material

A self-supporting electrode, vanadium pentoxide nanotechnology, applied in the field of preparation of vanadium oxide nanobelt/foam nickel composite self-supporting electrode materials, can solve the problems of difficult commercial applications, low electronic conductivity and ion conductivity, and poor structure. Stability and other issues, to achieve the effect of reducing sample morphology damage, increasing active injection sites, and large surface active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

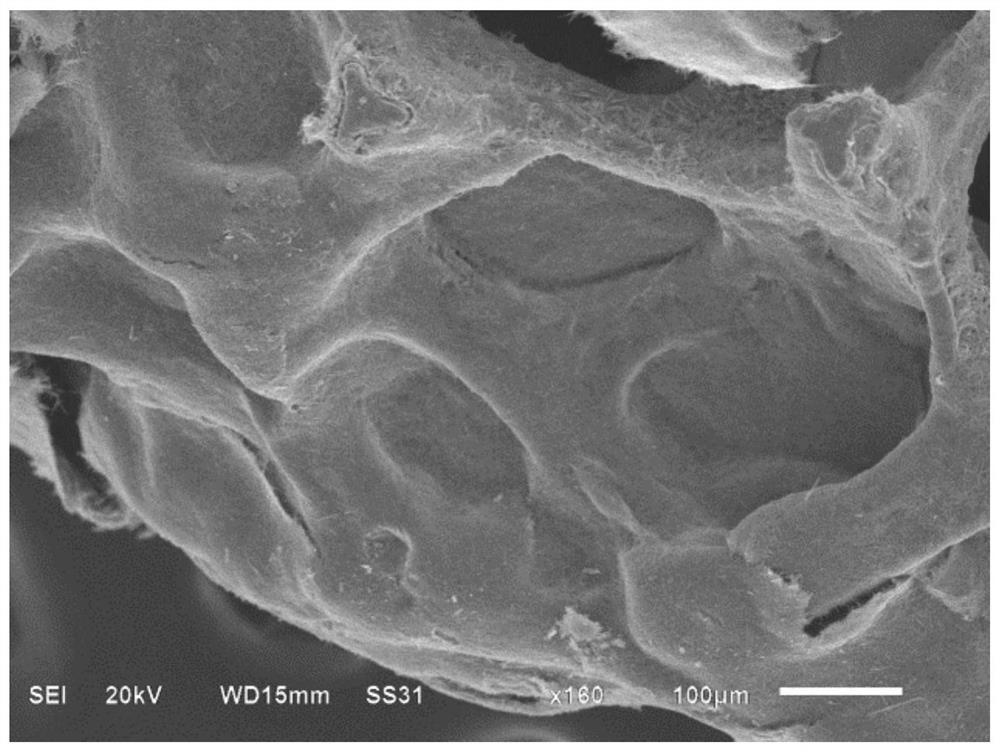

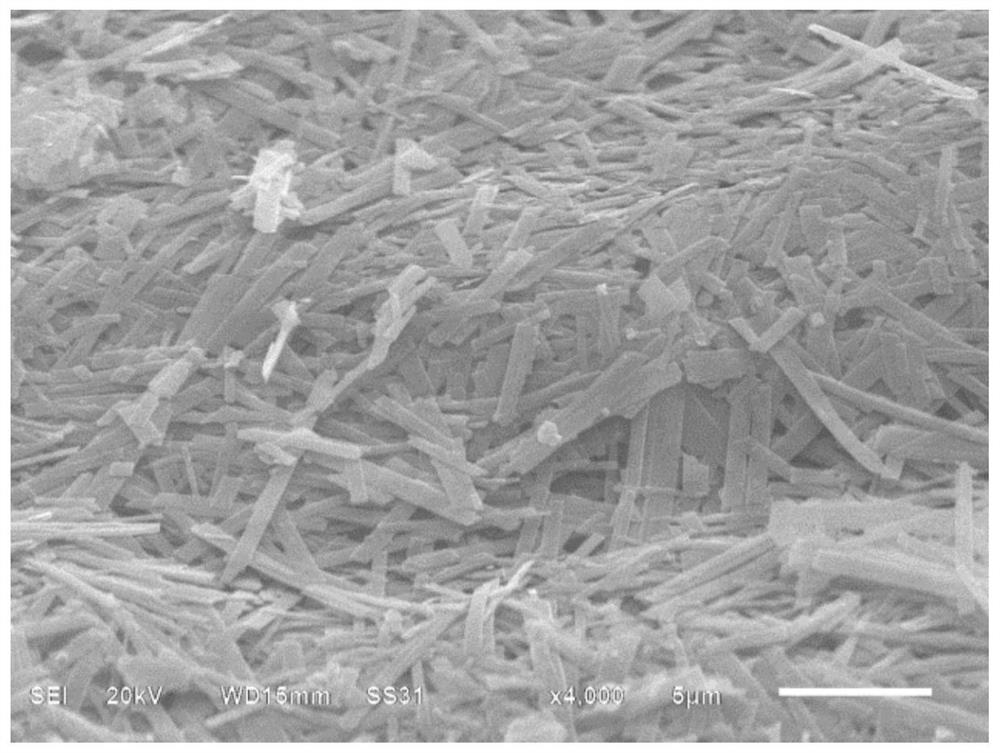

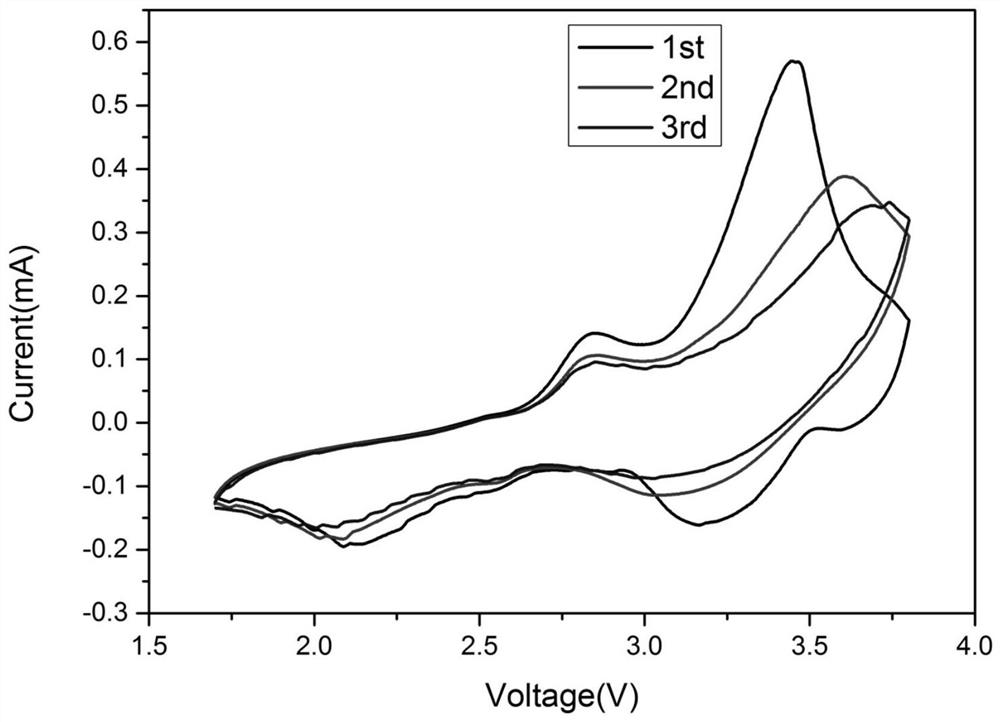

[0027] This embodiment provides a method for preparing a vanadium oxide nanobelt / nickel foam composite self-supporting electrode material, comprising the following steps:

[0028] S1: Take vanadium pentoxide powder and add it to deionized water, add hydrogen peroxide dropwise to the deionized water under stirring to completely dissolve the vanadium pentoxide powder, and then add a surfactant to the solution to obtain a vanadium-containing solution. The agent is a block copolymer of polyethylene oxide and polypropylene oxide, the molecular weight of polyethylene oxide in the block copolymer of polyethylene oxide and polypropylene oxide is 5000-20000, polypropylene oxide The molecular weight of the block is 2000-5000, and the concentration of the surfactant in the vanadium-containing solution is 4.8g / L;

[0029] S2: Put the nickel foam in the vanadium-containing solution, and react under pressure and heating conditions. The reaction temperature of the foam nickel and the vanadiu...

Embodiment 2

[0032] This embodiment provides a method for preparing a vanadium oxide nanobelt / nickel foam composite self-supporting electrode material, comprising the following steps:

[0033] S1: Take vanadium pentoxide powder and add it to deionized water, add hydrogen peroxide dropwise to the deionized water under stirring to completely dissolve the vanadium pentoxide powder, and then add a surfactant to the solution to obtain a vanadium-containing solution. The agent is a block copolymer of polyethylene oxide and polyacrylic acid, the molecular weight of polyethylene oxide in the block copolymer of polyethylene oxide and polyacrylic acid is 2000-5000, and the molecular weight of the polyacrylic acid block is 2000 ~10000, the concentration of the surfactant in the vanadium-containing solution is 7.5g / L;

[0034] S2: Put the nickel foam in the vanadium-containing solution, and react under pressure and heating conditions. The reaction temperature of the foam nickel and the vanadium-contai...

Embodiment 3

[0037] This embodiment provides a method for preparing a vanadium oxide nanobelt / nickel foam composite self-supporting electrode material, comprising the following steps:

[0038] S1: Take vanadium pentoxide powder and add it to deionized water, add hydrogen peroxide dropwise to the deionized water under stirring to completely dissolve the vanadium pentoxide powder, and then add a surfactant to the solution to obtain a vanadium-containing solution. The agent is a block copolymer of polyethylene oxide and polyacrylic acid, the molecular weight of polyethylene oxide in the block copolymer of polyethylene oxide and polyacrylic acid is 2000-5000, and the molecular weight of the polyacrylic acid block is 2000 ~10000, the concentration of the surfactant in the vanadium-containing solution is 10g / L;

[0039] S2: Put the nickel foam in the vanadium-containing solution, and react under pressure and heating. The reaction temperature of the foamed nickel and the vanadium-containing solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com